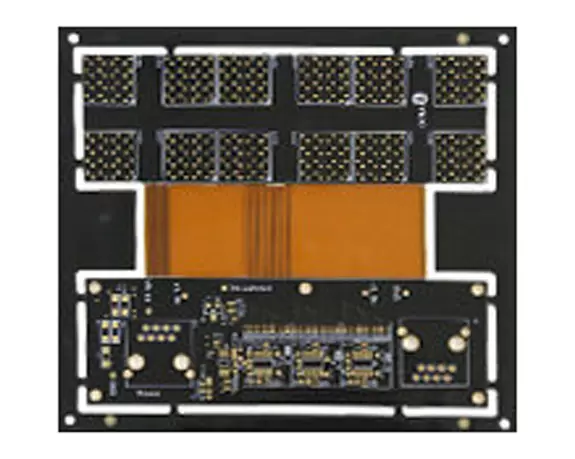

Integrated rigid sections with flexible tails for compact layouts

Integrated rigid sections with flexible tails for compact layouts

Vibration-resistant and reduces the need for connectors

Vibration-resistant and reduces the need for connectors

Simplifies assembly and improves long-term reliability

Simplifies assembly and improves long-term reliability

Enables 3D configurations for space-constrained applications

Enables 3D configurations for space-constrained applications

Used in aerospace, medical implants and premium wearables

Used in aerospace, medical implants and premium wearables

| Feature | Technical specification |

| Number of layers | 4 – 60 layers |

| Bending performance | Based on the specific design, the bend performance can range from a basic 90 bend to fit to a full dynamic flex with 360 range of motion in the flex tail that will withstand continuous cycles throughout the product life |

| Bend features | Bend radius controls the flexibility of the flex portion of the board. The thinner the material the lower the bend radius and the more flexible the flex section |

| Materials | RA copper, HTE copper, FR-4, polyimide, adhesive |

| Copper weights (finished) | 0.5 OZ – 6 OZ |

| PCB thickness | 0.40 mm – 6.0 mm |

| PCB thickness in flex section | 0.05mm x 0.8mm |

| Max. dimensions | 620 mm x 720 mm |

| Min. track and gap | 0.075 mm / 0.075 mm |

| Min. mechanical drill | 0.15 mm |

| Surface finishes available | HASL (SnPb), LF HASL (SnNiCu), OSP, ENIG, Immersion Tin, Immersion Silver, Electrolytic gold, Gold fingers |

![]()

Engineering Support

![]()

Prototyping Services

![]()

Fast Turnaround

![]()

Seamless Transition to Mass Production

What is the production process for a rigid-flex PCB like?

What is the production process for a rigid-flex PCB like?  What industries commonly use rigid-flex PCBs?

What industries commonly use rigid-flex PCBs?  What are the benefits of using a rigid-flex PCB?

What are the benefits of using a rigid-flex PCB?  How does a rigid-flex PCB differ from a standard PCB?

How does a rigid-flex PCB differ from a standard PCB?  What is a rigid-flex PCB?

What is a rigid-flex PCB?  Do rigid-flex PCBs have special quality requirements?

Do rigid-flex PCBs have special quality requirements? Yes. They need strict bend tests, good material control, and careful inspection to avoid cracks or layer separation during use.

Customer support