Copper on both sides supporting SMD and through-hole components

Copper on both sides supporting SMD and through-hole components

High cost-effectiveness with flexible layout options

High cost-effectiveness with flexible layout options

Typical for power modules and consumer electronics

Typical for power modules and consumer electronics

Allows for higher circuit density than single-sided designs

Allows for higher circuit density than single-sided designs

Ideal balance between performance and production cost for mid-range applications

Ideal balance between performance and production cost for mid-range applications

| Feature | Technical specification |

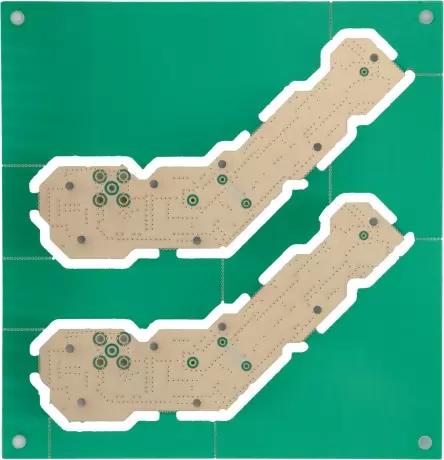

| Number of layers | 2 Layers |

| Materials | FR-4 standard, FR-4 high performance, FR-4 halogen-free |

| Copper weights (finished) | 0.5 oz – 6 oz |

| PCB Thickness | 0.40 mm – 6.0 mm |

| Max. dimensions | 620 mm x 720 mm |

| Min. track and gap | 0.075 mm / 0.075 mm |

| Min. mechanical drill | 0.15 mm |

| Surface finishes available | HASL (SnPb), LF HASL (SnNiCu), OSP, ENIG, Immersion Tin, Immersion Silver, Electrolytic gold, Gold fingers |

![]()

Engineering Support

![]()

Prototyping Services

![]()

Fast Turnaround

![]()

Seamless Transition to Mass Production

How does the trace routing differ in double sided PCBs compared to single sided PCBs?

How does the trace routing differ in double sided PCBs compared to single sided PCBs?  What are the advantages of double sided PCBs?

What are the advantages of double sided PCBs?  What is the process of manufacturing double sided PCBs?

What is the process of manufacturing double sided PCBs?  What is a double sided PCB?

What is a double sided PCB?

Customer support