Features extra-thick copper layers (typically >2oz) for high current-carrying capacity

Features extra-thick copper layers (typically >2oz) for high current-carrying capacity

Ideal for power electronics, motor controllers, and industrial equipment

Ideal for power electronics, motor controllers, and industrial equipment

Enhances thermal conductivity and improves heat dissipation

Enhances thermal conductivity and improves heat dissipation

Increases mechanical strength for high-reliability applications

Increases mechanical strength for high-reliability applications

Supports complex high-power designs while reducing the need for additional cooling

Supports complex high-power designs while reducing the need for additional cooling

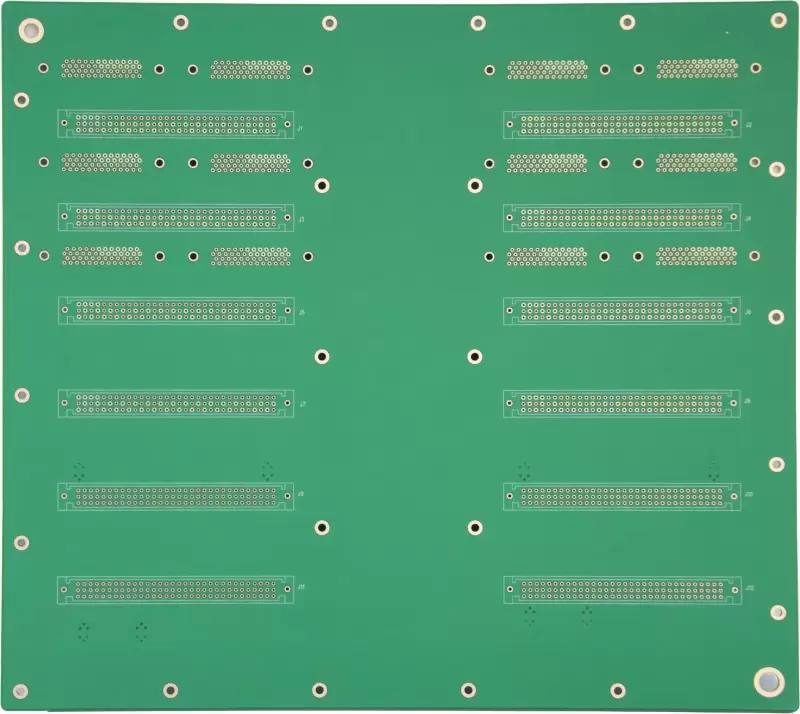

| Feature | Technical specification |

| Number of layers | 2-40 Layers |

| Materials | FR-4 standard, FR-4 high performance, FR-4 halogen-free |

| Copper weights (finished) | 2oz – 6 oz |

| PCB Thickness | 0.40 mm – 6.0 mm |

| Max. dimensions | 620 mm x 720 mm |

| Min. track and gap | 0.075 mm / 0.075 mm |

| Min. mechanical drill | 0.15 mm |

| Surface finishes available | HASL (SnPb), LF HASL (SnNiCu), OSP, ENIG, Immersion Tin, Immersion Silver, Electrolytic gold, Gold fingers |

![]()

Engineering Support

![]()

Prototyping Services

![]()

Fast Turnaround

![]()

Seamless Transition to Mass Production

Are there any design guidelines for thick copper PCBs?

Are there any design guidelines for thick copper PCBs?  Can SprintPCB produce multilayer thick copper PCBs?

Can SprintPCB produce multilayer thick copper PCBs?  What are the advantages of thick copper PCBs?

What are the advantages of thick copper PCBs?  What are the main applications of thick copper PCBs?

What are the main applications of thick copper PCBs?  What is considered a thick copper PCB?

What is considered a thick copper PCB?  What quality issues should I watch for with thick copper PCBs?

What quality issues should I watch for with thick copper PCBs? Pay attention to trace width, layer adhesion, and heat management. Work with an experienced manufacturer to avoid defects like uneven plating.

Customer support