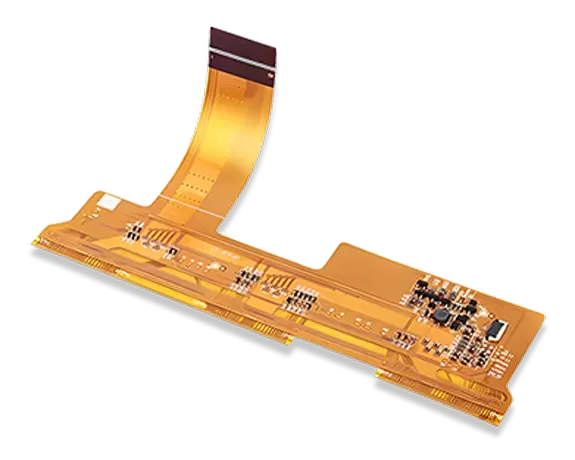

Ultra-thin, bendable and lightweight

Ultra-thin, bendable and lightweight

Adapts to dynamic folding and curved installations

Adapts to dynamic folding and curved installations

Eliminates the need for bulky connectors and cables in tight spaces

Eliminates the need for bulky connectors and cables in tight spaces

Offers excellent heat dissipation and reliability under mechanical stress

Offers excellent heat dissipation and reliability under mechanical stress

Used in automotive dashboards, rollable displays and flexible sensors

Used in automotive dashboards, rollable displays and flexible sensors

| Feature | Technical specification |

| Number of layers | 1-6 Layers |

| Materials | Polyimide, Polyester |

| Profile method | Laser cutting, punching, rout |

| Copper weights (finished) | 8 μm – 70 μm |

| FPC thickness | 0.05 mm – 0.80 mm |

| Max. dimensions | 250 mm x 610 mm |

| Min. track and gap | 0.05 mm / 0.05 mm |

| Min. mechanical drill | 0.1 mm |

| Surface finishes available | HASL (SnPb), LF HASL (SnNiCu), OSP, ENIG, Immersion Tin, Immersion Silver, Electrolytic gold, Gold fingers |

![]()

Engineering Support

![]()

Prototyping Services

![]()

Fast Turnaround

![]()

Seamless Transition to Mass Production

What is the difference between flexible and rigid-flex PCBs?

What is the difference between flexible and rigid-flex PCBs?  What materials are used to make flexible PCBs?

What materials are used to make flexible PCBs?  What types of applications are suitable for flexible PCBs?

What types of applications are suitable for flexible PCBs?  What are the benefits of using flexible PCBs?

What are the benefits of using flexible PCBs?  What is a flexible PCB?

What is a flexible PCB?  What should I know before ordering flexible PCBs?

What should I know before ordering flexible PCBs? Good design is key. Clear bend areas, proper materials, and choosing a supplier with flex PCB experience help avoid cracks or breaks.

Customer support