Introduction

In today’s fast-paced electronics landscape, the PCB Board serves as the backbone of virtually every device, from consumer gadgets to industrial machinery. At SprintPCB, we specialize in delivering cutting-edge PCB Board solutions tailored to meet the demands of engineers, startups, and Fortune 500 companies alike. This guide dives deep into the intricacies of PCB Board technology, offering actionable insights to optimize your projects for performance, reliability, and scalability.

What Is a PCB Board? The Foundation of Modern Electronics

A PCB Board (Printed Circuit Board) is a laminated substrate that mechanically supports and electrically connects electronic components using conductive pathways, pads, and traces. Unlike traditional point-to-point wiring, PCB Boards streamline assembly, reduce errors, and enhance repeatability.

- Core Components: Substrate (FR-4, ceramic), copper layers, solder mask, silkscreen.

- Applications: Smartphones (miniaturized PCB Boards), automotive systems (high-temperature boards), medical devices (flexible circuits).

- Why It Matters: A well-designed PCB Board ensures signal integrity, thermal management, and compliance with industry standards like IPC-6012.

7 Unbeatable Advantages of High-Performance PCB Boards

Investing in premium PCB Boards pays dividends across the product lifecycle:

- Precision Engineering: Laser-drilled microvias and tight tolerances (±0.05mm) for complex designs.

- Durability: Flame-retardant substrates (UL94-V0) withstand harsh environments.

- Signal Integrity: Controlled impedance traces minimize EMI/RFI interference.

- Cost Efficiency: Automated assembly reduces labor costs by 40–60%.

- Scalability: Rapid prototyping to mass production with consistent quality.

- Sustainability: Lead-free finishes (ENIG, HASL) align with RoHS directives.

- Customization: Support for rigid, flex, and rigid-flex PCB Boards.

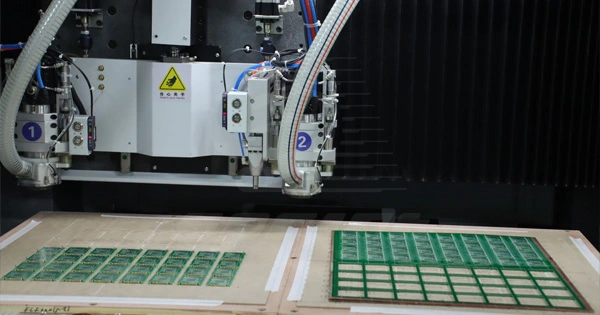

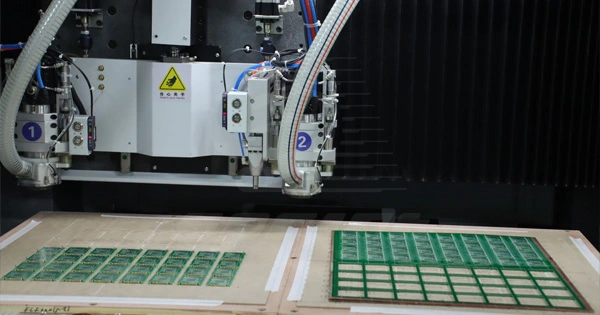

Behind the Scenes: SprintPCB’s PCB Board Manufacturing Excellence

Our PCB Board production process combines cutting-edge technology with rigorous quality control:

Design Validation

- DFM/DFA checks to eliminate errors in Gerber files.

- 3D simulations for thermal and mechanical stress analysis.

Material Selection

- High-Tg FR-4 for automotive/military applications.

- Polyimide for flexible PCB Boards in wearables.

Layer Stacking & Etching

- Laser direct imaging (LDI) for 6μm trace width accuracy.

- Plasma etching for HDI boards.

Testing & Certification

- Automated optical inspection (AOI) and flying probe testing.

- IPC Class 3 compliance for mission-critical applications.

How to Select the Perfect PCB Board: A Buyer’s Checklist

Avoid costly mistakes by evaluating these factors:

- Material: FR-4 (budget-friendly), Rogers 4350B (high-frequency), aluminum (heat dissipation).

- Layer Count: 1–2 layers for simple circuits vs. 12+ layers for advanced computing.

- Surface Finish: ENIG (corrosion resistance) vs. OSP (cost-effective for short shelf life).

- Certifications: ISO 9001, IATF 16949 (automotive), and ITAR (defense).

Top 5 PCB Board Design Pitfalls (and How to Fix Them)

Even seasoned engineers stumble over these issues:

- Insufficient Clearance: Traces spaced <0.2mm risk short circuits.

- Fix: Follow IPC-2221 guidelines for spacing.

- Thermal Hotspots: Poor heat dissipation reduces component lifespan.

- Fix: Add thermal vias and copper pours.

- Signal Crosstalk: Parallel routing of high-speed lines.

- Fix: Use ground planes and differential pairs.

- DFM Neglect: Ignoring fab house capabilities.

- Fix: Collaborate early with your PCB Board manufacturer.

- Overcomplicated Layouts: Excessive layers inflate costs.

- Fix: Simplify with modular design practices.

Why Engineers Trust SprintPCB for PCB Board Solutions

With 15+ years of expertise, SprintPCB stands out through:

- Speed: 24-hour prototyping turnaround for urgent projects.

- Precision: Advanced equipment for 0.1mm microvia drilling.

- Global Support: Factories in the US, China, and Germany.

- Transparency: Real-time order tracking and detailed test reports.

Conclusion

Whether you’re developing an IoT sensor or a satellite communication system, mastering PCB Board design and manufacturing is non-negotiable. Partner with SprintPCB to leverage our technical prowess, industry certifications, and customer-first philosophy.

Ready to elevate your project? Request a free PCB Board quote today and join 10,000+ satisfied clients!