Printed Circuit Boards (PCBs) are integral components in electronic devices. They provide electrical connections and support between electronic components, enabling circuits to function properly.

The quality and reliability of PCBs are crucial for the performance, stability, and lifespan of electronic devices. Therefore, choosing a reliable PCB manufacturer is essential to ensure product quality and a smooth production process.

Here are several key reasons to understand the importance of PCB manufacturers.

Reliable PCB manufacturers possess extensive knowledge and experience in PCB design, manufacturing, and assembly. They are familiar with the latest PCB technologies and industry standards, providing professional advice and support to ensure that PCB designs and manufacturing meet requirements.

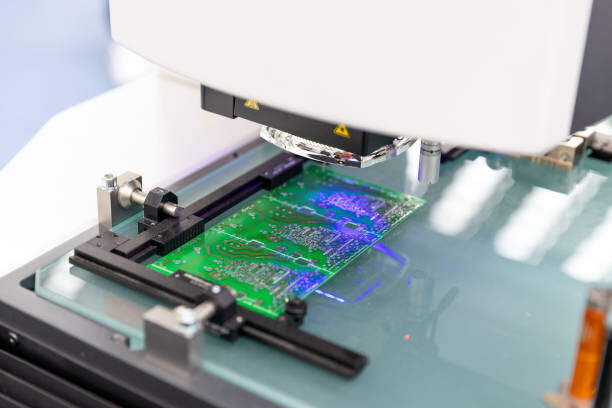

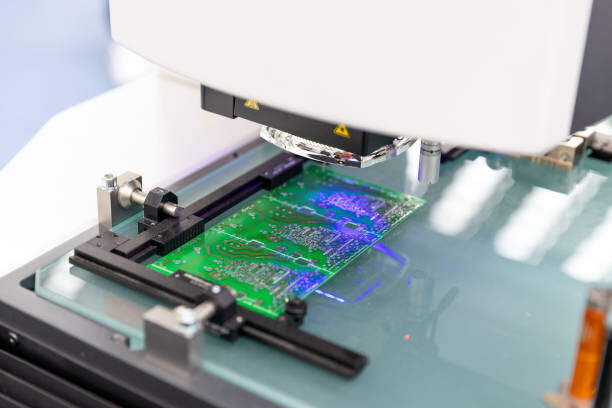

Reliable PCB manufacturers implement stringent quality control measures to ensure that the produced PCBs adhere to high-quality standards. They utilize advanced inspection equipment and techniques, including electrical testing, X-ray inspection, and visual inspection.

Through rigorous quality control processes, reliable manufacturers can deliver PCBs that meet specifications, reducing failure rates and minimizing the risk of repairs and recalls.

Reliable PCB manufacturers have excellent production capacity and supply chain management capabilities to meet customer demands and deliver on time. They typically have state-of-the-art production equipment and automated processes to improve production efficiency and capacity utilization.

This ensures that PCB production can be completed on time, even within tight project schedules, avoiding production delays and losses.

Reliable PCB manufacturers usually offer comprehensive technical support and after-sales service. They can address customer questions during PCB design, material selection, and production processes. After PCB delivery, they provide timely troubleshooting and product return services to ensure customer satisfaction.

In conclusion, selecting a reliable PCB manufacturer is crucial for ensuring the quality, production capacity, and after-sales support of PCBs. A close and dependable partnership with a professional manufacturer can provide high-quality PCBs, assisting customers in achieving success in a competitive market.

Therefore, understanding their expertise, quality control capabilities, production capacity, and after-sales services is vital when evaluating and selecting PCB manufacturers.

Before selecting a reliable PCB manufacturer, it is essential to define your requirements and establish evaluation criteria.

This will help you assess the capabilities of different manufacturers and find the most suitable partner for your needs. Here are some detailed steps and considerations.

Identify the type and specifications of the PCB:

PCB type: Determine whether you need a single-sided, double-sided, or multi-layer PCB.

PCB size and shape: Define the dimensions and shape limitations based on your application requirements.

PCB materials and thickness: Specify the desired substrate material (e.g., FR-4) and layer thickness requirements.

Define quality requirements:

Establish quality standards and specifications for the PCB, such as IPC standards (IPC-A-600, IPC-A-610, etc.).

Consider reliability and durability requirements, especially for applications exposed to high temperatures, humidity, or vibrations.

Determine quantity and delivery time:

Identify the required quantity of PCBs to find manufacturers capable of meeting your batch requirements.

Consider project timelines to ensure manufacturers can deliver the PCBs on time.

Consider manufacturer certifications and quality control:

Identify your certification requirements for manufacturers, such as ISO 9001 Quality Management System certification.

Understand the manufacturer's quality control processes and testing methods to ensure they can provide PCBs that meet the standards.

Consider supply chain and environmental requirements:

Understand the manufacturer's supply chain management capabilities, including raw material sourcing and supplier partnerships.

Consider environmental requirements to ensure the manufacturer complies with relevant regulations and sustainable development principles.

Consider after-sales service and technical support:

Ensure the manufacturer can provide timely technical support and after-sales service to address potential issues and provide assistance.

Understand the manufacturer's troubleshooting processes, product return and exchange policies, and the quality of their after-sales service.

Consider pricing and commercial terms:

Consider the price levels of PCB manufacturers, aligning with your budget and quality requirements.

Compare the commercial terms of different manufacturers, such as payment methods, delivery terms, and warranty periods.

By clearly defining your requirements and criteria, you will be able to selectively screen and evaluate PCB manufacturers more effectively, choosing a reliable manufacturer that aligns with your project's specific needs and standards.

Researching and collecting relevant information is a crucial step in evaluating and selecting a reliable PCB manufacturer.

This information will help you understand the manufacturer's capabilities, quality control measures, reputation, and customer feedback. Here are some detailed steps to conduct research and collect information.

Use search engines and online directories: Utilize search engines like Google, Bing, or online directories to find PCB manufacturers' websites and online listings. Input relevant keywords such as "reliable PCB manufacturers" or "PCB manufacturer reviews" to obtain related search results. This will provide you with some manufacturer names and website addresses.

Visit the manufacturer's website: Visiting the manufacturer's official website is a vital way to gather detailed information. Explore their website to learn about their service range, production capabilities, quality control systems, and customer support. Check if their website appears professional, if the information is clear, and if they provide detailed information about their manufacturing processes and quality management.

Refer to customer reviews and social media feedback: Seeking customer reviews and feedback can provide insights into the manufacturer's actual performance. Look for customer reviews of the manufacturer or search for relevant discussions on industry forums and social media platforms. This feedback can provide information about the manufacturer's reliability, quality, and customer service.

Attend industry exhibitions and events: Industry exhibitions and events serve as another avenue to learn about PCB manufacturers. These events often attract numerous suppliers and manufacturers. You can engage in face-to-face conversations with manufacturer representatives, ask questions about their business and capabilities, and obtain their promotional materials and contact information.

Consider the manufacturer's experience and industry reputation: Understanding the manufacturer's experience and reputation is a key factor in selecting a reliable manufacturer.

Look into the manufacturer's history, years in operation, and the clients and projects they have worked with.

Consider choosing manufacturers with a good industry reputation and extensive experience, as this often signifies reliable manufacturing capabilities and quality assurance.

Seek advice and opinions from others: Engage in conversations with industry professionals, colleagues, or friends to seek their advice and experiences regarding reliable PCB manufacturers.

Their recommendations and insights can be highly valuable and provide suggestions for trustworthy manufacturers.

Reference customer feedback and reputation

Customer feedback and reputation are important criteria for evaluating the reliability of a manufacturer. You can obtain customer feedback and reputation through the following methods.

Search online forums and social media: Look for discussions and reviews related to PCB manufacturers. User experiences shared on these platforms can help you understand the manufacturer's reputation and customer satisfaction.

Seek recommendations and testimonials: Consult industry peers, suppliers, or other relevant individuals for their advice and recommendations on reliable manufacturers. Their experiences and opinions can provide valuable guidance for your selection.

Request samples and conduct trial production

Requesting samples and conducting small-scale trial production is an effective method to assess the quality and capabilities of a manufacturer. Here are the relevant steps.

Approach potential manufacturers for sample requests: Contact the manufacturers and ask them to provide samples so that you can personally evaluate their quality and technical expertise.

Assess the quality of samples: Carefully examine the appearance, dimensions, materials, and workmanship of the samples. Ensure that they meet your requirements and standards.

Conduct small-scale trial production: Collaborate with the manufacturer to carry out a small-scale trial production. This will help you understand the manufacturer's production capacity, delivery capabilities, and responsiveness.

Consider cost and delivery time

Cost and delivery time are factors that need to be considered holistically when selecting a manufacturer. Here are some considerations.

Compare prices from different manufacturers: Request quotes from multiple manufacturers and compare their prices. Note that the lowest price does not always indicate the best choice; you need to balance the relationship between price and quality.

Inquire about delivery time: Ensure that the manufacturer can deliver your orders on time. Learn about their production cycle, logistics processes, and delivery guarantees.

By conducting comprehensive research and collecting information, you will gain a detailed understanding of various PCB manufacturers.

This will help you narrow down your options and select reliable manufacturers that meet your requirements and standards. Remember, ongoing research and information gathering are crucial for making informed decisions.

When selecting a reliable PCB manufacturer, it is crucial to assess their capability and reputation.

Here are some detailed steps and considerations.Experience and Technical Expertise

Investigate the manufacturer's experience and industry reputation to understand their years in the PCB manufacturing field and expertise.

Check if the manufacturer possesses advanced production equipment and technologies, such as advanced printing, plating, and quality inspection equipment.

Assess whether the manufacturer has the capability to handle complex designs and special requirements, such as multilayer boards, rigid-flex boards, or high-frequency boards.

Quality Control System and Certification Standards

Understand the manufacturer's quality control system, such as ISO 9001 certification, to ensure their product quality meets international standards.

Check for other certifications, such as ISO 14001 environmental management system certification, indicating the manufacturer's environmental responsibility.

Ensure that the manufacturer adopts traceability and rigorous quality inspection processes to ensure thorough testing and inspection at every production stage.

Supply Chain Management and Reliability Assurance

Assess the manufacturer's supply chain management capabilities, including raw material procurement, inventory management, and supplier selection.

Verify if the manufacturer works with reliable suppliers and partners to ensure the quality and timely delivery of raw materials.

Explore the manufacturer's stocking strategy and emergency response plan to ensure supply reliability and stability.

Reference Customer Evaluations and Social Media Feedback

Review the manufacturer's website and official materials to understand their partner and customer list.

Look for evaluations and feedback about the manufacturer on relevant industry forums, social media, and online discussion groups.

Pay attention to key indicators in customer reviews, such as on-time delivery, product quality, and after-sales service performance.

Visit the Manufacturer's Factory and Facilities

If possible, personally visit the manufacturer's factory and production facilities.

Observe the manufacturer's production line and process flow to understand their production capacity and quality control measures.

Engage in face-to-face communication with the manufacturer's team to inquire about their capability and reputation.

Considering the above factors collectively will help evaluate the manufacturer's capability and reputation, assisting you in selecting a reliable PCB manufacturer to meet your requirements and ensure high-quality products and services.

Before selecting a reliable PCB manufacturer, it is crucial to understand their importance in ensuring the quality and performance of the final product.

Here are some detailed insights into understanding the importance of PCB manufacturers.

Key Role: PCBs are the core components of modern electronic devices, providing the necessary connections and support between electronic components. The quality and performance of the PCB directly impacts the stability and reliability of the entire electronic device. A reliable PCB manufacturer can deliver high-quality printed circuit boards, ensuring the proper functioning of the device.

Technical Expertise: A reliable PCB manufacturer should possess advanced technical capabilities and expertise. They should be well-versed in various types of PCB designs and manufacturing requirements, offering customized solutions based on clients' needs. They should have state-of-the-art production equipment and process technologies to ensure high-quality PCB production.

Quality Control: A reliable PCB manufacturer should have stringent quality control systems in place. They should employ various quality inspection and testing methods to ensure that each PCB complies with specifications and standards. Comprehensive functional testing, reliability testing, and environmental adaptability testing should be conducted to ensure the stability and durability of the PCB under different operating conditions.

Supply Chain Management: A reliable PCB manufacturer should have effective supply chain management systems. They should establish long-term partnerships with reliable raw material suppliers to ensure the availability of high-quality materials. They should have robust inventory management and delivery capabilities to meet customer demands promptly.

Reliability Assurance: A reliable PCB manufacturer should provide reliability assurance measures. They should have appropriate warranty policies and be able to offer prompt responses and solutions to address any quality issues or failures. They should have a strong after-sales service and technical support team to promptly address customer inquiries and provide necessary assistance.

Understanding the importance of PCB manufacturers will help you clarify your expectations and requirements during the selection process. By partnering with a reliable manufacturer, you can ensure that you receive high-quality and reliable PCBs, thereby enhancing the overall quality and competitiveness of your final product.

When evaluating and selecting a reliable PCB manufacturer, comparing quotes and business terms is a crucial step.

This step can help you make informed decisions balancing economic benefits and business conditions. Here are some detailed descriptions and suggestions to assist you in the comparison process.

Request quotes from multiple manufacturers

Send inquiries to several potential PCB manufacturers, asking them to provide detailed quotes tailored to your requirements.

Ensure you provide sufficient information to manufacturers, such as PCB specifications, layers, material requirements, surface finishes, impedance control, etc., to ensure that the quotes received are based on the same requirements.

Compare prices

Focusing solely on the lowest price may lead to quality and service issues, so it's important to consider prices along with other factors.

Evaluate the quotes from each manufacturer, ensuring the prices are reasonable and align with your budget.

Pay attention to delivery time

Ensure that the quotes include clear delivery times. If your project has time constraints, choosing a manufacturer capable of delivering on time is crucial.

Consider payment terms

Compare the manufacturers' payment terms and methods. Understand whether they accept installment payments or other flexible payment options that match your financial requirements.

Factor in after-sales service

Inquire about the manufacturers' after-sales service policies. Understand if they provide product warranties, repair support, and replacement services.

Review business terms

Carefully read and compare the business terms of each manufacturer. Pay attention to special terms, return policies, order cancellation provisions, etc.

Consider production capacity

If your project requires large-scale production, ensure that the manufacturer has sufficient capacity to meet your needs.

Seek negotiation opportunities

After comparing quotes and business terms, if necessary, you can engage in further negotiations with manufacturers to seek better prices and business conditions.

Consider all these factors and make decisions based on your needs and priorities. Selecting a manufacturer with reasonable pricing, favorable business terms, and a good reputation ensures you receive high-quality PCBs along with satisfactory delivery and after-sales service.

After-sales service and support are crucial factors to consider when selecting a reliable PCB manufacturer.

An excellent manufacturer not only provides high-quality products but also offers comprehensive after-sales support to ensure customer satisfaction and long-term partnerships.

When considering after-sales service and support, here are some important aspects to consider.

Technical Support: The manufacturer should be able to provide professional technical support to assist customers in resolving any potential issues. They should have a skilled team of engineers who can address customer's technical inquiries, provide consultations, and offer advice.

Troubleshooting: The manufacturer should have well-established troubleshooting procedures and solutions in place. If any issues or failures occur during the use of PCBs, the manufacturer should be able to respond promptly and provide appropriate solutions to minimize production downtime and losses.

Repair and Warranty Policies: Understanding the manufacturer's repair and warranty policies is crucial. They should offer reasonable warranty periods and conditions and clearly state how faults and repair requests are handled during the warranty period. Additionally, knowing their repair process and turnaround time is essential to ensure timely resolution when repairs are needed.

After-Sales Service Response Time: Timely response to after-sales service inquiries is a key factor in assessing a manufacturer's reliability. The manufacturer should be able to respond quickly when customers raise questions or request support and take appropriate actions to address the issues.

After-Sales Training and Support Materials: The manufacturer can provide training and support materials to help customers better understand and utilize their PCB products. These training courses may include product introductions, operating guidelines, troubleshooting tips, and more. Offering these resources can increase customer satisfaction and enhance their trust in the manufacturer.

Supply Chain Flexibility: The manufacturer should have supply chain flexibility to adjust and support customers' needs and changes. They should have backup suppliers and inventory management systems in place to ensure timely supply of the required PCB products during emergency situations.

Customer Feedback and References: Reviewing customer testimonials and references can provide valuable insights into the quality of after-sales service and support. Understanding the experiences and feedback of other customers can help assess whether the manufacturer excels in this aspect.

In conclusion, selecting a manufacturer that provides timely technical support and comprehensive after-sales service is crucial for long-term partnerships. When evaluating and selecting a PCB manufacturer, it is essential to consider the aspects of after-sales service and support and choose manufacturers that excel in these areas to ensure the best fulfillment of your PCB requirements.

When selecting a manufacturer, maintaining ongoing communication and collaboration is crucial. Ensure to establish a good working relationship with the manufacturer and communicate your needs and expectations in a timely manner to ensure the final PCB product meets your requirements.

By considering the factors mentioned above comprehensively, you will be able to evaluate and select a reliable PCB manufacturer who can provide high-quality PCB products for your project and ensure the success and continuous development of the partnership.

SprintPCB: Your Reliable PCB Support Provider SprintPCB is a renowned high-tech enterprise offering comprehensive PCB manufacturing services to clients globally. With our extensive expertise and cost-effective solutions, you can prioritize your organization's critical requirements while enjoying a seamless process. Get in touch with us today and discover how we can assist you.