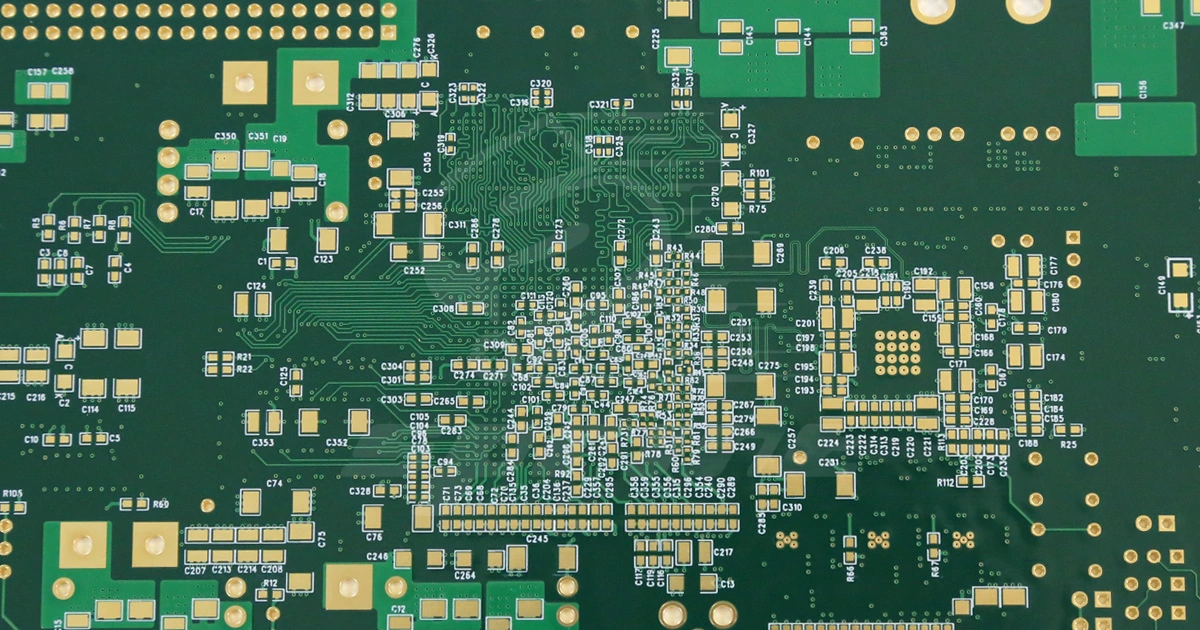

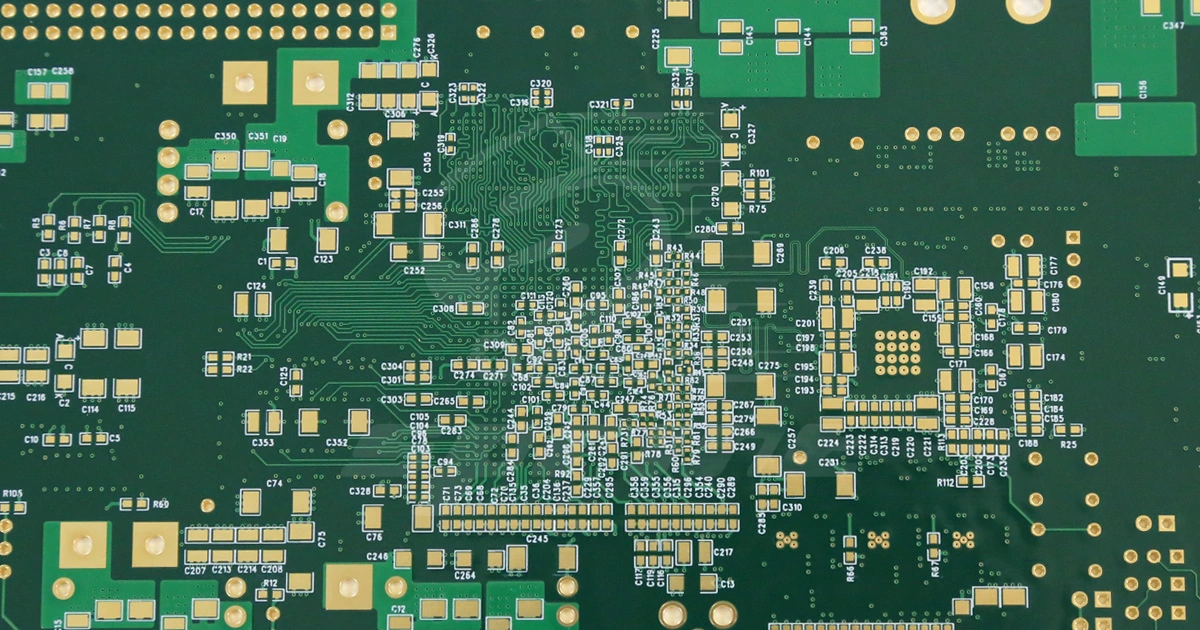

PCB circuit boards achieve circuit functionality by connecting electronic components together. This article will comprehensively introduce the technical characteristics and application value of PCB circuit boards from aspects such as PCB specifications, parameters, features, advantages, and application scenarios.

1. PCB Specifications

PCB circuit boards come in a variety of specifications and models. Depending on different application needs and the size requirements of electronic devices, different specifications and models can be selected. Common PCB specifications include single-sided boards,

double-sided boards, and multilayer boards.

Among them,

multilayer boards are made by stacking multiple layers of circuit boards, allowing for more complex circuit layouts and higher levels of integration.

2. Product Parameters

Materials: PCB circuit boards typically use fiberglass-reinforced materials, such as FR-4, which have good insulation properties and mechanical strength.

Thickness: The thickness of PCB circuit boards usually ranges from 0.2mm to 6.0mm, with different thicknesses chosen based on specific needs.

Line Width and Spacing: The line width and spacing of PCB circuit boards determine the board's conductivity and signal transmission speed, generally reaching 0.1mm.

Hole Diameter: The hole diameter on PCB circuit boards is used for installing components and making circuit connections, with common diameters being 0.3mm and 0.4mm.

3. Product Features

High Reliability: PCB circuit boards are manufactured using professional processes and strict quality control, resulting in high reliability and stability, capable of operating in harsh environments.

High Density: PCB circuit boards enable tight component layouts and high integration, enhancing the performance and functionality of electronic devices.

Good Conductivity: PCB circuit boards use metal wires to connect electronic components, providing good conductivity for high-speed signal transmission and stable current output.

Ease of Manufacturing and Assembly: PCB circuit boards employ standardized manufacturing processes and automated assembly equipment, significantly improving production efficiency and product quality.

4. Product Advantages

Enhanced Performance: PCB circuit boards allow for tight component layouts and high integration, reducing circuit length and signal transmission time, thereby improving the performance and response speed of electronic devices.

Cost Reduction: The standardized and automated manufacturing processes of PCB circuit boards greatly reduce production costs and improve production efficiency.

Ease of Maintenance and Upgrading: Components on PCB circuit boards can be easily disassembled and replaced, facilitating the maintenance and upgrading of electronic devices and extending the product's lifespan.

Environmental Friendliness: PCB circuit boards use lead-free soldering processes and environmentally friendly materials, meeting environmental standards and reducing pollution.

5. Application Scenarios

PCB circuit boards are widely used in electronic devices across various fields, such as communication equipment, computers, consumer electronics, and medical devices.

Communication Equipment: In communication equipment, PCB circuit boards are used to achieve signal transmission and processing, ensuring stability and reliability in communication.

Computers: In computers, PCB circuit boards are used to connect various hardware components, enabling data transmission and processing.

Consumer Electronics: In consumer electronics, PCB circuit boards are used to achieve control and interaction of various functional modules.

Medical Devices: PCB circuit boards use lead-free soldering processes and environmentally friendly materials, meeting environmental standards and reducing pollution.