At a critical stage where the global automotive industry is shifting toward intelligence and electrification, the performance and stability of core electronic components have become key factors in competition among automakers. With deep expertise in the mid-to-high-end PCB sector, SprintPCB has become a strategic partner for many overseas automotive manufacturers. Today, using the case of a European automotive electronics supplier, we will analyze in detail how SprintPCB, from the first contact to long-term cooperation, leverages meticulous service and professional capabilities to help automotive clients overcome production challenges.

Over the past 18 years, SprintPCB has developed into a one-stop manufacturer specializing in R&D and production of mid-to-high-end, multi-layer PCBs. Relying on a dual-drive model of “global coverage” and “localized support,” the company's business now spans more than 86 countries and regions worldwide. It has established service centers in East China, South China, North China, and the United States, and formed dedicated international client service teams to provide full-process localized support. To date, SprintPCB has served more than 10,000 enterprises globally.

The client in this case is a well-known European automotive electronics supplier (core partners include Tesla and Ford, with main products in vehicle intelligent control systems such as autonomous driving perception modules and in-vehicle infotainment systems). With the booming demand for new energy vehicles, the client faced multiple stringent requirements in PCB procurement that their original supplier could no longer meet. They therefore launched a new supplier selection process, and after multiple rounds of technical evaluation and vendor comparison, decided to conduct their first on-site visit to SprintPCB in China.

High Reliability PCB Demand: Vehicle intelligent control systems operate in temperature ranges from -40℃ to 125℃ and must withstand continuous vibration during driving. This requires exceptional temperature resistance and anti-vibration performance. Particularly for autonomous driving perception modules, PCBs must feature 10+ layer high-density designs to ensure millimeter-wave radar and camera signals transmit without delay. Any circuit failure could trigger serious safety risks.

Global Synchronized Supply Requirement: The client has three major production bases in North America, Mexico, and Germany. They require suppliers to achieve “one order, global distribution,” with delivery cycles for each base controlled within 7–10 days to prevent supply chain disruptions that could delay automaker assembly.

Compliance and Certification Standards: As an automotive supplier, PCBs must comply with the IATF16949 automotive quality management certification, while materials must meet international environmental standards such as RoHS and REACH to ensure access to major global automotive markets.

To ease the unfamiliarity of their first visit to China, SprintPCB's foreign trade team spent a week preparing a customized reception plan: booking a four-star hotel 20 minutes from the company, preparing a bilingual itinerary map of "Airport - Hotel - Company" in Chinese and English (marking convenient facilities); after the customer arrives in Shenzhen, the team will pick up the customer at the airport with a sign printed with the customer's logo, assist with luggage handling and explain local travel precautions.During the visit, meals were specially prepared in line with the client's dietary restrictions, offering a mix of Chinese and Western cuisine. This thoughtful, professional service left the client feeling welcomed and reassured. By the end of the visit, they had already expressed a clear intention to cooperate.

Customized High-Reliability PCB Development with Proactive Technical Support:

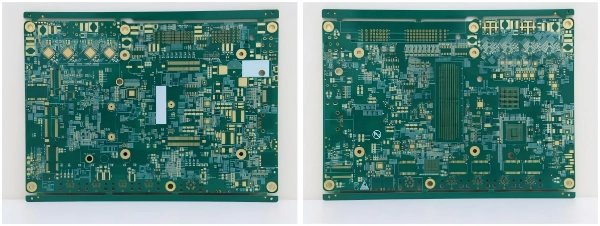

After the partnership began, SprintPCB set up a dedicated technical team to develop products tailored to automotive working conditions. For the autonomous driving perception module PCB, the team applied blind and buried via technology and 3.0mil ultra-fine line processing to optimize signal transmission, controlling signal delay within 5ns. They also introduced a “design pre-review” mechanism: whenever the client sent Gerber files, SprintPCB completed a proactive review within 2 hours, checking layout, via design, and material compatibility. On one occasion, the engineering team discovered that a certain line spacing in the design failed to meet insulation requirements for high-temperature automotive environments. Producing the board as-is could have caused a short-circuit risk. SprintPCB immediately drafted a detailed illustrated report explaining the issue and proposed optimizations, helping the client eliminate risks at the design stage.

End-to-End Quality Control:

Based on the IATF16949 system, SprintPCB established a 12-step quality control process from raw material procurement to finished product delivery. It works with world-class suppliers like DuPont and Hitachi, with each batch undergoing temperature resistance and insulation tests. During production, AOI (Automated Optical Inspection) and X-Ray inspection systems are used for 100% accuracy checks of circuits and solder joints. These multi-dimensional inspections ensure every PCB delivered to the client is defect-free.

Efficient Logistics and Customs Support:

Before shipment, photos of product appearance and packaging are taken and sent along with packing lists and quality reports for client confirmation. Only after confirmation is logistics arranged. SprintPCB maintains close cooperation with DHL and FedEx to provide full-process “door-to-door” logistics services. The foreign trade team also prepares certificates of origin and compliance documents in advance according to each country's tariff and customs policies, ensuring smooth customs clearance for both samples and bulk orders.

Product Significant Reliability Improvements:

After adopting SprintPCB PCBs, the client's vehicle intelligent control system failure rate dropped from 3.2% to 0.3%. The autonomous driving perception module achieved 18 consecutive months of zero failures, earning high recognition from automakers such as Tesla and Ford. As a result, the client's order volume increased by 40% compared to pre-cooperation levels.

Optimized Global Supply Chain Efficiency:

Through a “global warehouse + local distribution” model, the average delivery cycle of the client's three production bases was shortened from 15 days to 8 days, with the Mexico base even achieving 3-day express delivery. This eliminated supply chain disruptions and enabled the client to secure a major annual order from Ford's new energy vehicle program.

Reduced Compliance Costs:

SprintPCB's PCBs are pre-certified with IATF16949, RoHS, and other standards, sparing the client additional testing costs. Market entry timelines were shortened by 30%. In 2024 alone, this saved the client more than USD 200,000 in compliance testing expenses.

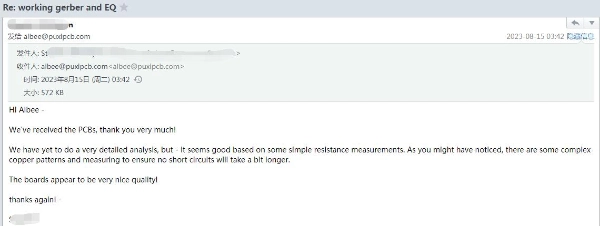

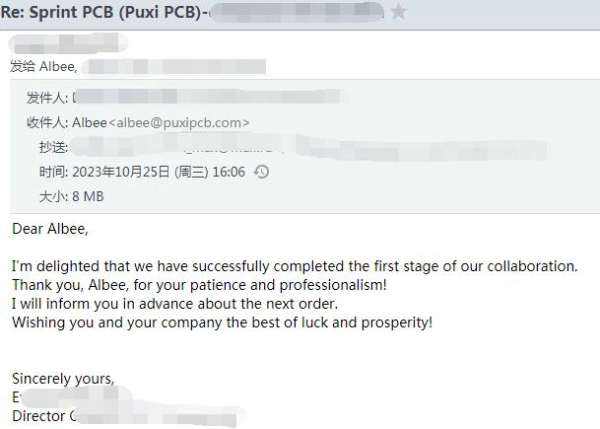

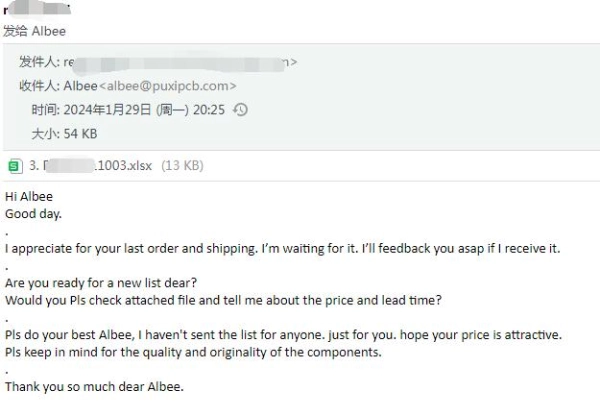

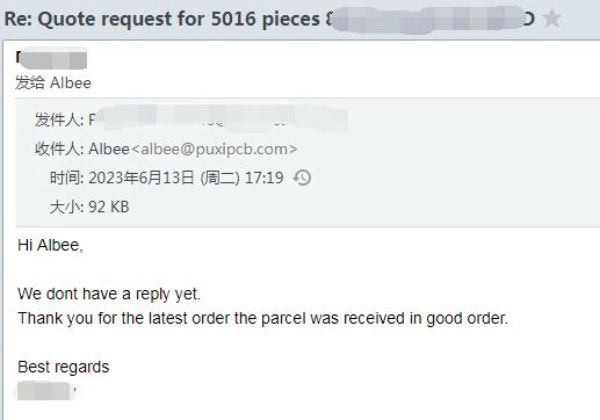

In addition to strong recognition from the European medical equipment manufacturer, many overseas clients have also expressed their satisfaction through messages and emails.

SprintPCB consistently leverages its dual advantages of “global coverage” and “localized support” to provide tailored solutions for overseas clients across industries. This collaboration with a European automotive electronics supplier not only highlights SprintPCB's technological strength in high-end, multi-layer PCBs, but also validates the reliability of its global service system. Looking ahead, SprintPCB will continue to deepen its focus in automotive electronics and industrial control, delivering higher-quality products and services to help global clients achieve breakthroughs in their industrial transformations.

Customer support