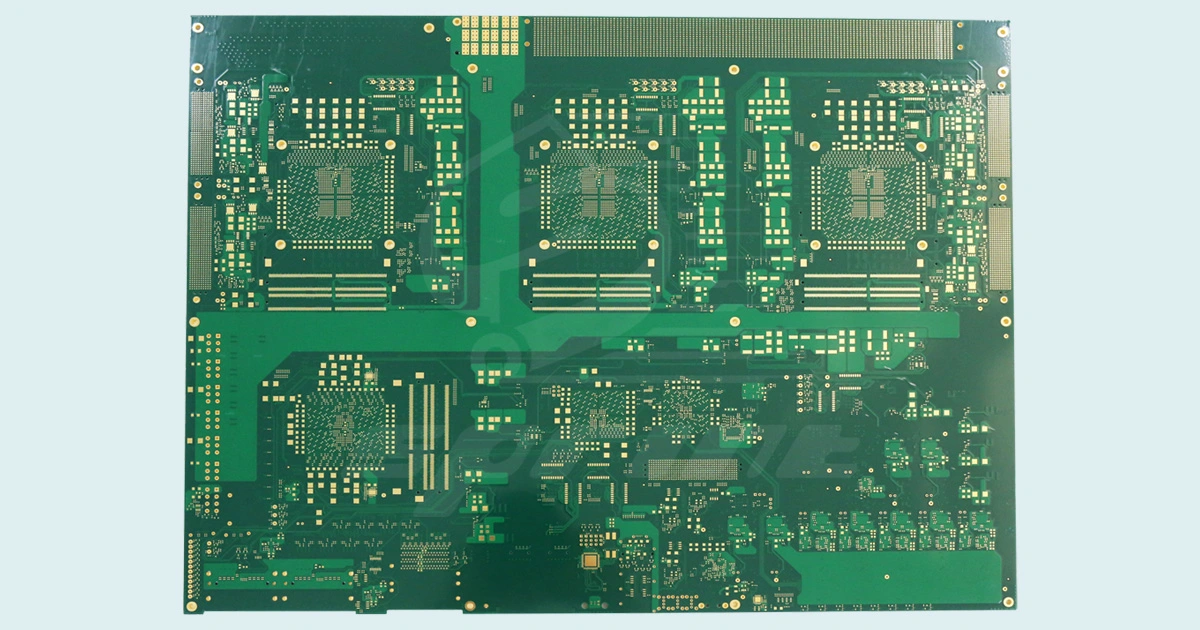

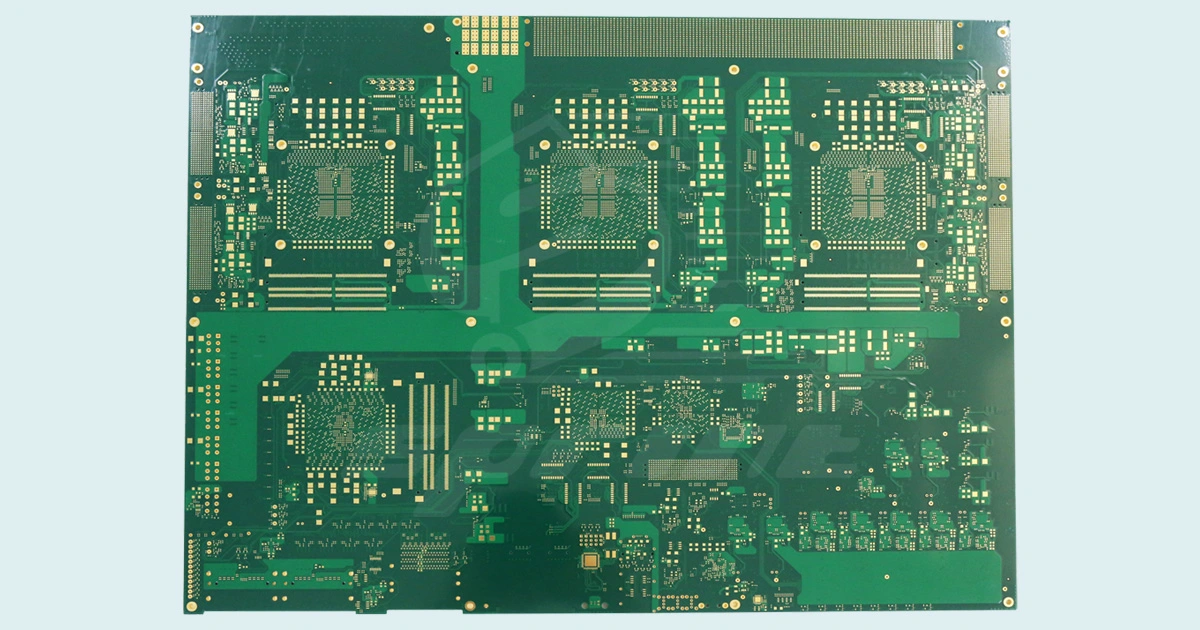

In the world of electronic manufacturing, rigid printed circuit boards (PCBs) have been a cornerstone component for decades. Among the various types of PCBs, Original Design Manufacturer (ODM) rigid PCBs stand out as an exemplary blend of precision engineering and performance reliability. These boards are designed to meet specific customer requirements and are often used in applications where a high level of mechanical stability is essential.

What are ODM Rigid PCBs?

Original Design Manufacturers (ODMs) specialize in creating unique designs for customers who cannot develop their products. ODM rigid PCBs are thus custom-designed boards that cater to specific project requirements. Unlike standardized mass-produced PCBs, ODM PCBs offer unique features and dimensions tailored to the precise needs of the client's application.

- Customizable Designs: ODM rigid PCBs are designed according to the unique specifications provided by the customer, allowing for tailored track widths, hole sizes, board thicknesses, and more.

- High-Quality Materials: These boards are typically made from high-grade materials such as FR4, which provides excellent mechanical stability and temperature resistance.

- Precision Manufacturing: ODM PCBs undergo strict quality control processes to ensure tight tolerances and high accuracy in the final product.

- Versatile Application: With custom designs, these PCBs can be used in a wide range of industries, from telecommunications to automotive, aerospace, and consumer electronics.

- Long-Term Reliability: The robust construction and high-quality materials used in ODM rigid PCBs ensure extended product lifespan and reliability under harsh conditions.

Benefits of Using ODM Rigid PCBs:

- Specific Requirements: Customers can dictate the exact requirements for their project, ensuring that the final product meets their specific technical and functional needs.

- Cost-Effective: While initial setup costs may be higher than standard PCBs, long-term savings can be realized due to reduced revision cycles and fewer compatibility issues.

- Shorter Time-to-Market: By working directly with an ODM, customers can reduce the time needed to bring their products to market since the design phase aligns closely with their project timeline.

- Enhanced Performance: Custom-designed PCBs can be optimized for performance, reducing electrical noise and improving signal integrity.

- Unique Solutions: For complex or novel projects where off-the-shelf solutions are not available, ODM rigid PCBs provide a pathway to success.

Applications of ODM Rigid PCBs:

The applications for ODM rigid PCBs are virtually limitless, but some common examples include:

- Medical Devices: Where reliability and precision are critical for patient safety.

- Aerospace: Extreme temperatures and vibrations require robust PCBs that can withstand harsh environments.

- Automotive: From advanced driver assistance systems to infotainment units, custom PCBs are essential for modern vehicles.

- Consumer Electronics: Portable devices like smartphones and tablets demand compact, high-performance PCBs.

- Industrial Control: Industrial automation and control systems rely on PCBs that can handle both the physical environment and the need for reliable connectivity.

As technology continues to advance, the demand for customized solutions in electronic manufacturing grows. ODM rigid PCBs provide a flexible foundation for companies looking to create innovative products that push the boundaries of what is possible. With their ability to be precisely engineered for specific applications, these PCBs promise enhanced performance, reliability, and a competitive edge in today's fast-paced electronics market.