Common Surface Finishes include HASL (Hot Air Solder Leveling), Lead-free HASL, Electroless Nickel Immersion Gold (ENIG), Electroless Nickel Immersion Tin (ENT), Electroless Silver (ImAg), Hard Gold Plating, Flash Gold, Finger Connectors (Connecting Fingers), and Nickel Palladium Gold (NiPdAu). OSP (Organic Solderability Preservative) is known for its low cost, good solderability, strict storage requirements with short shelf life, environmental friendliness, excellent soldering performance, and a smooth

surface finish.

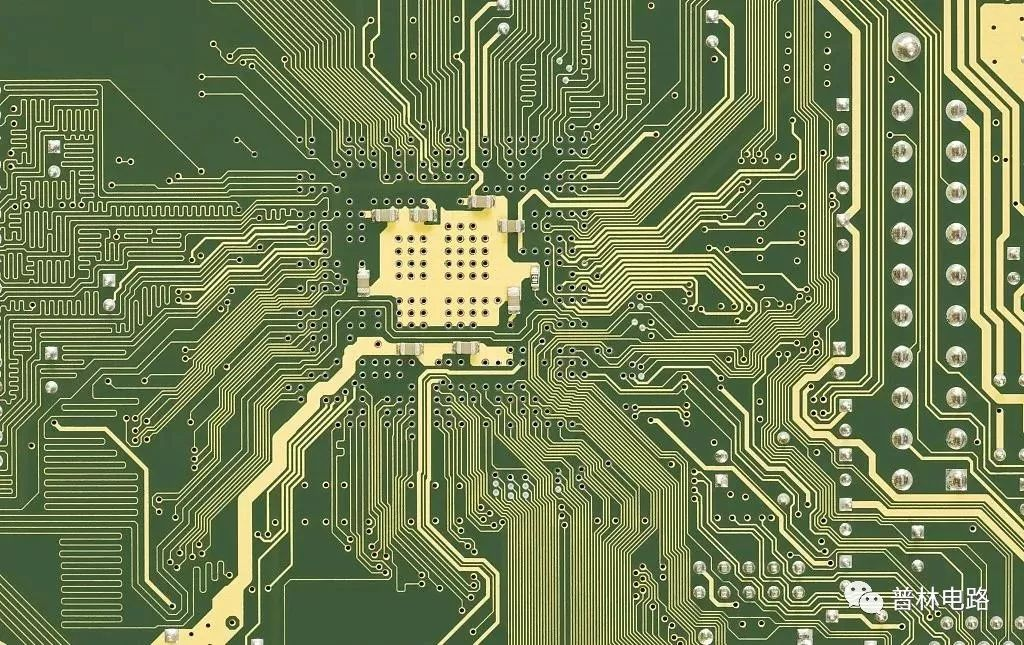

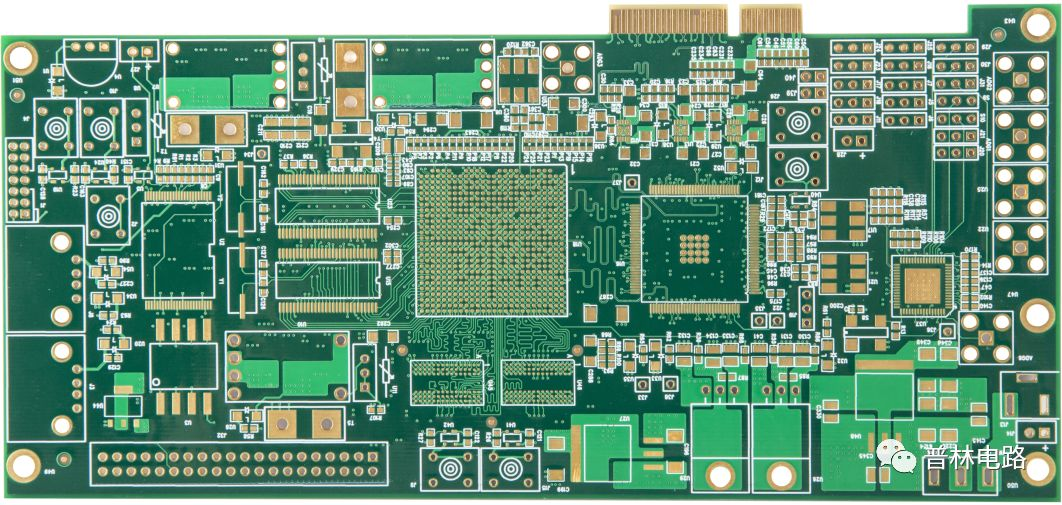

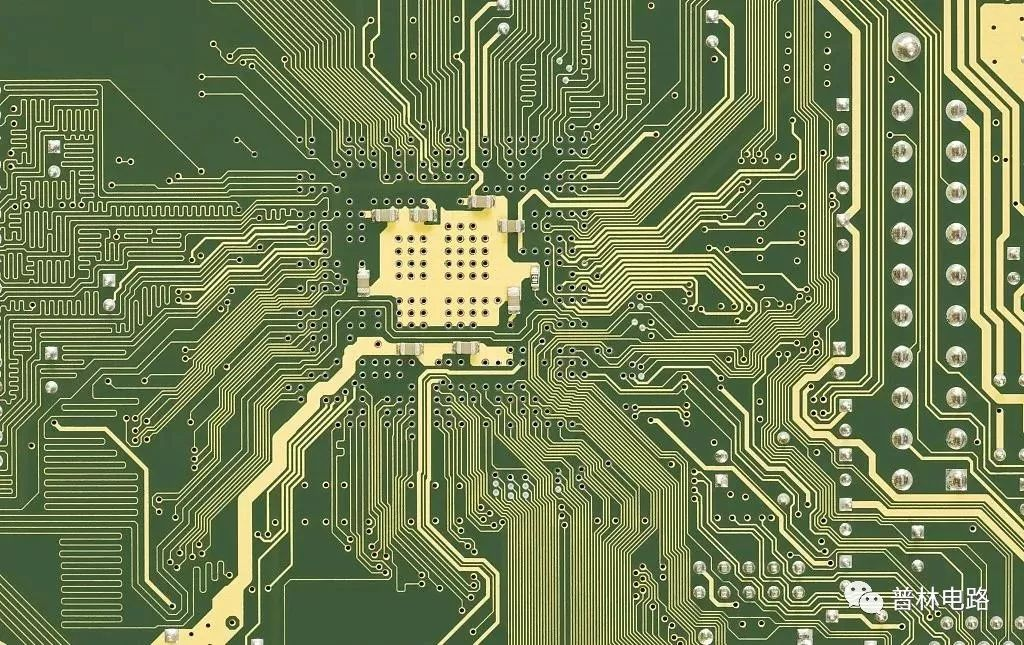

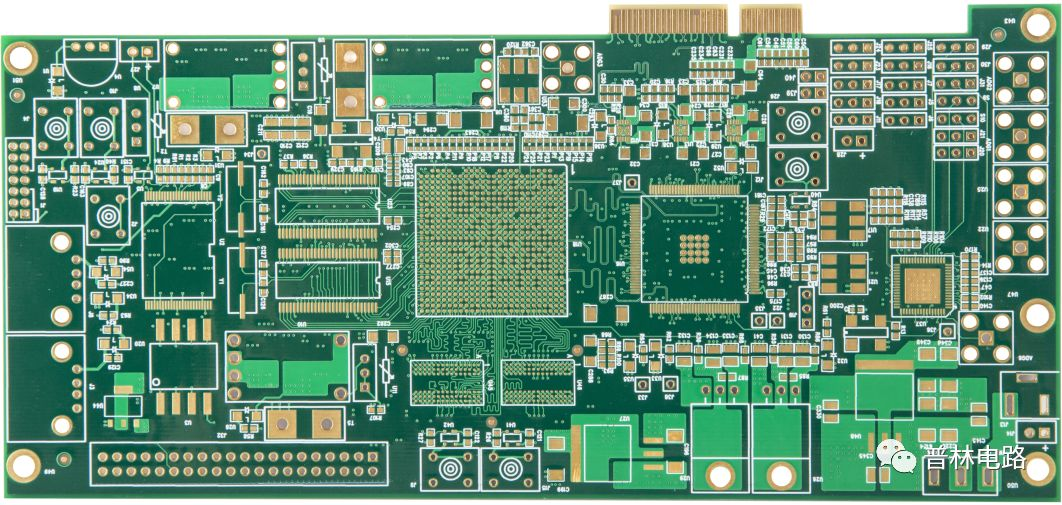

HASL boards, typically used for multi-layer (4 to 46 layers) high-precision PCB prototypes, find application in large-scale communications, computing, medical equipment, and aerospace sectors. Connecting fingers, composed of numerous gold-plated conductive contacts, ensure signal transmission between memory modules and sockets, owing to gold's high resistance to oxidation and conductivity.

Why Use Gold Plated Boards

With increasing IC integration density and more densely packed pins, HASL struggles to achieve flatness on fine pads, posing challenges for SMT assembly. Moreover, HASL boards have a limited shelf life. Gold plating addresses these issues effectively:

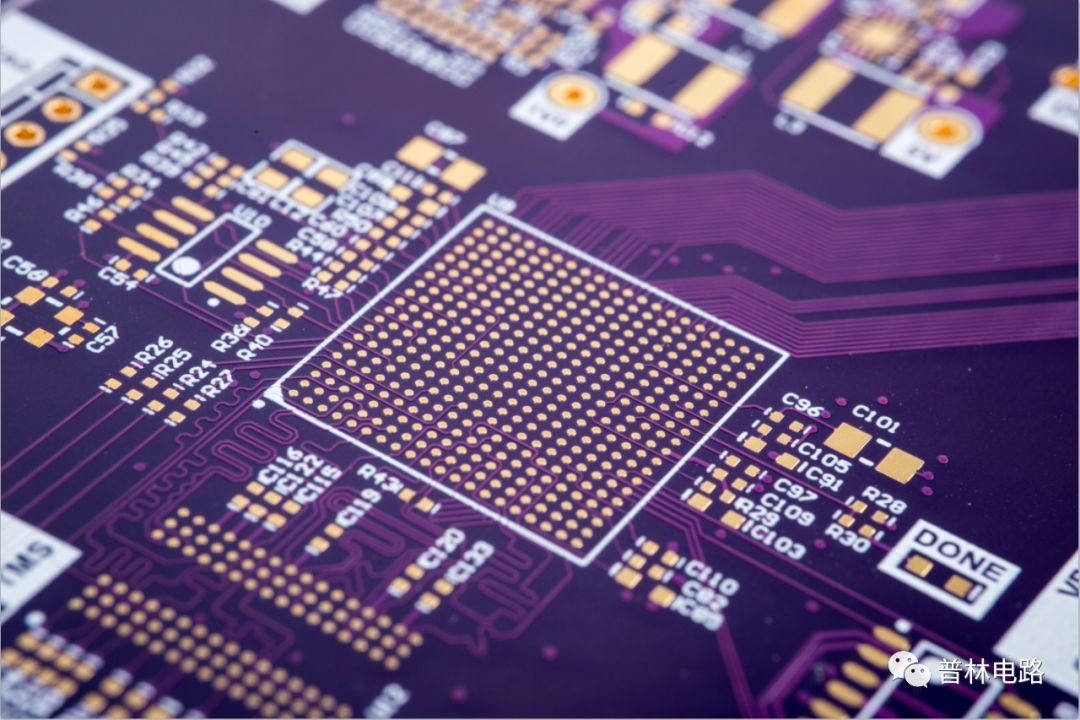

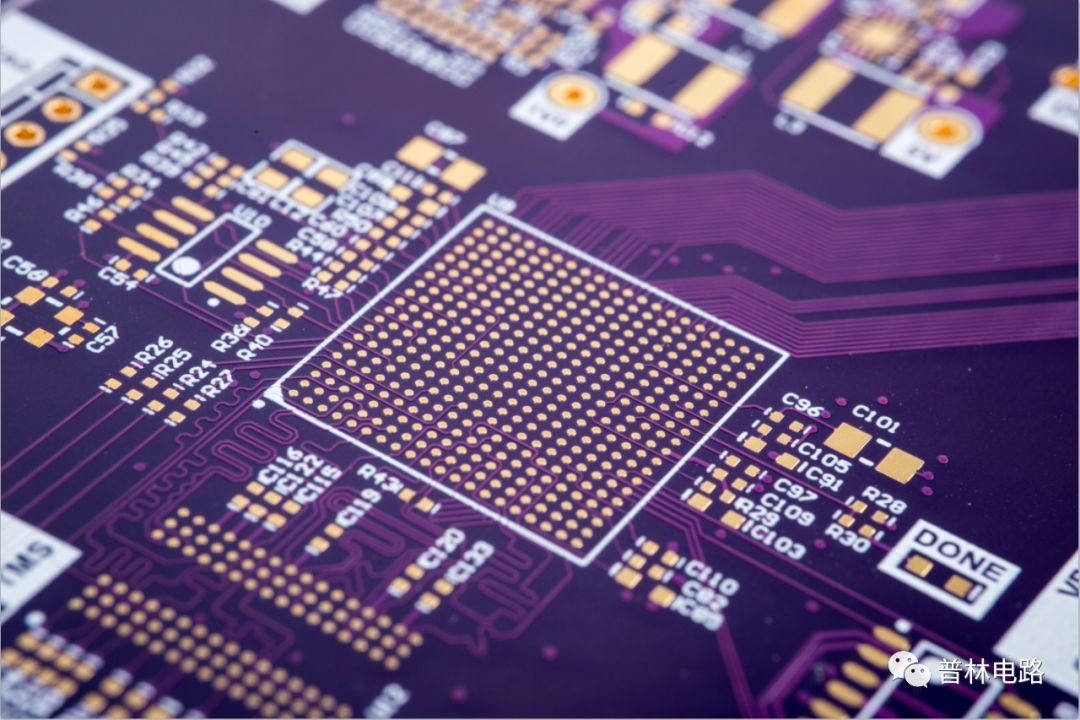

In surface mount technology, particularly with 0603 and smaller 0402 components, pad flatness is crucial to the quality of solder paste printing, which significantly influences the outcome of reflow soldering. Thus, full-board gold plating is commonly seen in high-density and ultra-miniature SMT processes. Gold-plated boards also boast a much longer shelf life compared to lead-tin alloys, making them a preferred choice. Notably, during the prototype stage, the cost difference between gold-plated and lead-tin alloy boards is negligible.

However, as trace widths and spacing narrow down to 2.5 mils, gold whisker shorts become an issue. Additionally, at higher signal frequencies, skin effect—where high-frequency currents tend to flow near the conductor surface—more significantly impacts signal integrity in multi-layered coatings.

Why Use ENIG (Immersion Gold) Boards

To tackle these issues with gold plating, ENIG boards exhibit the following characteristics:

1. ENIG presents a more vibrant yellow color than electroplated gold, appealing to customers.

2. ENIG is easier to solder due to its crystal structure, reducing poor soldering and customer complaints.

3. With ENIG, signals travel through the copper layer, unaffected by the skin effect.

4. Eliminates gold whiskers that could cause micro-shorts.

5. Enhances adhesion between solder mask and copper due to selective plating.

6. Does not affect spacing during compensation adjustments.

7. Offers better stress control for bonding processes, although softer than electroplated gold, making it less suitable for wear-resistant gold fingers.

8. ENIG boards offer similar flatness and shelf life to electroplated gold boards.

ENIG vs. Electroplated Gold Boards

Electroplating gold exists in two forms: electroplating and immersion (ENIG). For solderability, ENIG generally performs better. Unless binding is specifically required, manufacturers often opt for ENIG. Common PCB surface finishes include electroplated or immersion gold, silver plating, OSP, HASL (lead and lead-free), primarily for FR-4 or CEM-3 substrates. If solderability issues arise excluding factors from solder paste or manufacturing, PCB-related reasons might include:

1. Presence of oil residue on the pads, affecting solderability, verifiable via tinning tests.

2. Adequacy of pad design to support components.

3. Contamination of pads, determinable through ion contamination testing.

Each Surface Finish has its advantages and disadvantages. Electroplated gold extends PCB storage time, tolerates wider environmental temperature and humidity fluctuations, and can last up to a year. HASL follows, then OSP, both requiring careful attention to storage conditions. Immersion silver differs, being more expensive, requiring stringent storage with a maximum shelf life of about three months. In terms of solderability, ENIG, OSP, and HASL are comparably effective; manufacturers consider the cost-benefit ratio when deciding.

SprintPCB, with 17 years of

PCB manufacturing experience, specializes in producing a variety of high-layer-count precision circuit boards, blind and buried vias, high-frequency boards, hybrid laminates, metal core boards, and rigid-flex circuits. For inquiries, please feel free to contact us at

sales@puxipcb.com.

HASL boards, typically used for multi-layer (4 to 46 layers) high-precision PCB prototypes, find application in large-scale communications, computing, medical equipment, and aerospace sectors. Connecting fingers, composed of numerous gold-plated conductive contacts, ensure signal transmission between memory modules and sockets, owing to gold's high resistance to oxidation and conductivity.

HASL boards, typically used for multi-layer (4 to 46 layers) high-precision PCB prototypes, find application in large-scale communications, computing, medical equipment, and aerospace sectors. Connecting fingers, composed of numerous gold-plated conductive contacts, ensure signal transmission between memory modules and sockets, owing to gold's high resistance to oxidation and conductivity. In surface mount technology, particularly with 0603 and smaller 0402 components, pad flatness is crucial to the quality of solder paste printing, which significantly influences the outcome of reflow soldering. Thus, full-board gold plating is commonly seen in high-density and ultra-miniature SMT processes. Gold-plated boards also boast a much longer shelf life compared to lead-tin alloys, making them a preferred choice. Notably, during the prototype stage, the cost difference between gold-plated and lead-tin alloy boards is negligible.

However, as trace widths and spacing narrow down to 2.5 mils, gold whisker shorts become an issue. Additionally, at higher signal frequencies, skin effect—where high-frequency currents tend to flow near the conductor surface—more significantly impacts signal integrity in multi-layered coatings.

In surface mount technology, particularly with 0603 and smaller 0402 components, pad flatness is crucial to the quality of solder paste printing, which significantly influences the outcome of reflow soldering. Thus, full-board gold plating is commonly seen in high-density and ultra-miniature SMT processes. Gold-plated boards also boast a much longer shelf life compared to lead-tin alloys, making them a preferred choice. Notably, during the prototype stage, the cost difference between gold-plated and lead-tin alloy boards is negligible.

However, as trace widths and spacing narrow down to 2.5 mils, gold whisker shorts become an issue. Additionally, at higher signal frequencies, skin effect—where high-frequency currents tend to flow near the conductor surface—more significantly impacts signal integrity in multi-layered coatings. To tackle these issues with gold plating, ENIG boards exhibit the following characteristics:

1. ENIG presents a more vibrant yellow color than electroplated gold, appealing to customers.

2. ENIG is easier to solder due to its crystal structure, reducing poor soldering and customer complaints.

3. With ENIG, signals travel through the copper layer, unaffected by the skin effect.

4. Eliminates gold whiskers that could cause micro-shorts.

5. Enhances adhesion between solder mask and copper due to selective plating.

6. Does not affect spacing during compensation adjustments.

7. Offers better stress control for bonding processes, although softer than electroplated gold, making it less suitable for wear-resistant gold fingers.

8. ENIG boards offer similar flatness and shelf life to electroplated gold boards.

To tackle these issues with gold plating, ENIG boards exhibit the following characteristics:

1. ENIG presents a more vibrant yellow color than electroplated gold, appealing to customers.

2. ENIG is easier to solder due to its crystal structure, reducing poor soldering and customer complaints.

3. With ENIG, signals travel through the copper layer, unaffected by the skin effect.

4. Eliminates gold whiskers that could cause micro-shorts.

5. Enhances adhesion between solder mask and copper due to selective plating.

6. Does not affect spacing during compensation adjustments.

7. Offers better stress control for bonding processes, although softer than electroplated gold, making it less suitable for wear-resistant gold fingers.

8. ENIG boards offer similar flatness and shelf life to electroplated gold boards.