Incorporating flying probe testing (FPT) into

printed circuit board (PCB) assembly processes offers several advantages. Here are some of the key benefits:

- Cost-effective: FPT is a cost-effective testing method, especially for smaller-sized volumes. It is more affordable than alternatives such as in-circuit testing.

- Low up-front costs: Compared to in-circuit testing, FPT has lower up-front costs. There are zero expenses associated with test fixtures for flying probe tests.

- Ideal for small- to medium-sized productions: FPT is well-suited for low-volume production due to its low development costs and short development times. Although it may not be suitable for larger volume productions, it can still be utilized for samples and prototypes.

- Greater flexibility: The automation of FPT allows for increased flexibility for test changes. Despite having limitations on some more complicated tests, the ability to handle changes makes this method beneficial.

- Accuracy and precision: Flying probes can position test probes with a high level of accuracy and reliability. They are extremely precise and help to prevent problems with the finished products.

- Shorter lead development time: In most cases, the run time for a flying probe test takes approximately five to 15 minutes per board, depending on its size.

- High-tech features: FPT is starting to include high-tech features like phase difference measurement (PDM) units and micro shorts detection.

- Less custom tooling: FPT does not require custom tooling like in-circuit testing, which contributes to lower upfront costs and startup times.

Optimal inspection: Pairing flying probe testing with automated optical inspection (AOI) confirms that each part is properly formatted and placed on printed circuit boards, thanks to its extreme accuracy.

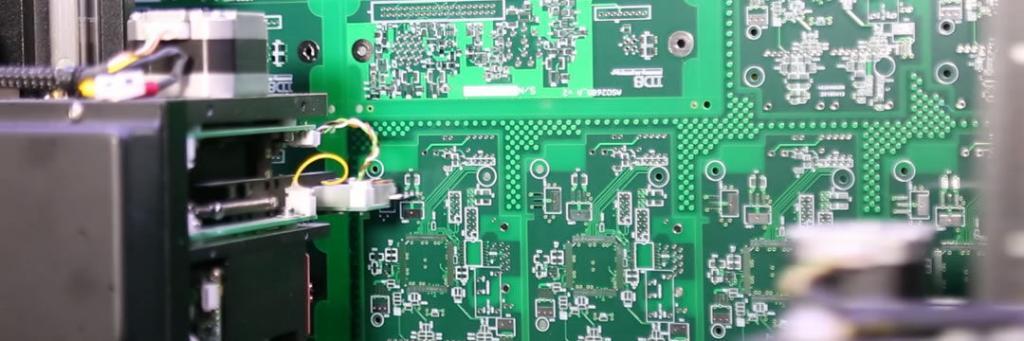

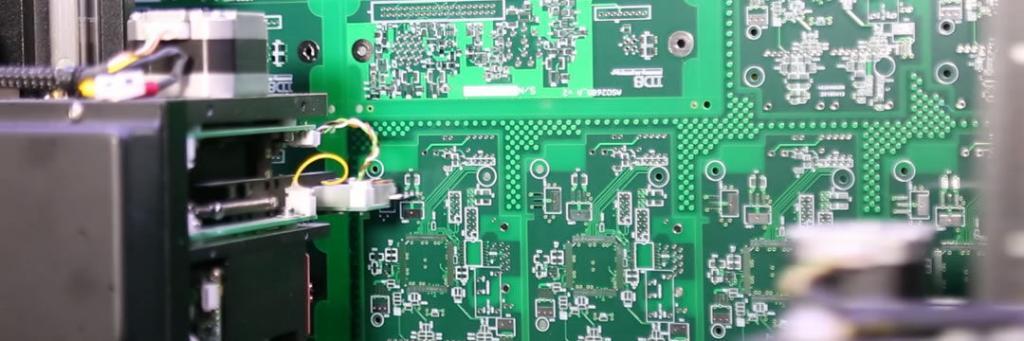

What Is Flying Probe Testing?

Flying probe testing is a method of testing electronic printed circuit boards during the manufacturing process. The process involves using probes that "fly" to contact test points simultaneously. A flying probe tester typically utilizes one or multiple test probes to make contact with the PCB on both the top and bottom to access test points. They then move across the circuit board to test multiple conductors or components. The machines follow a program that outlines the specific board being tested, and use highly precise needles to ensure the PCB is functioning properly.

Flying probe testing systems do not require any test fixturing or custom tooling, and the probes have very few restrictions regarding board access. This makes FPT a cost-effective choice for testing boards in their earliest stages of development. It is also ideal for low- to mid-volume production.