As electronic devices evolve, the demand for more compact and sophisticated circuit boards continues to rise. Multilayer PCBs, especially 10 layer PCBs, are becoming essential for high-performance, compact applications in industries ranging from telecommunications to automotive. SprintPCB, a leading

10 layer PCB manufacturer, provides reliable, high-quality PCB manufacturing solutions tailored to meet the needs of complex electronic systems.

In this article, we will explain what a 10 layer PCB is, key design considerations, the benefits of 10 layer PCBs, their applications, and why SprintPCB is your go-to manufacturer for multilayer PCBs.

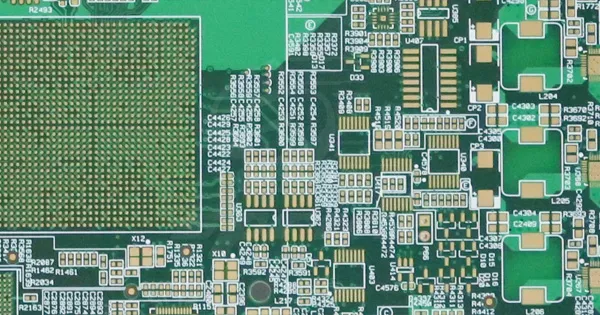

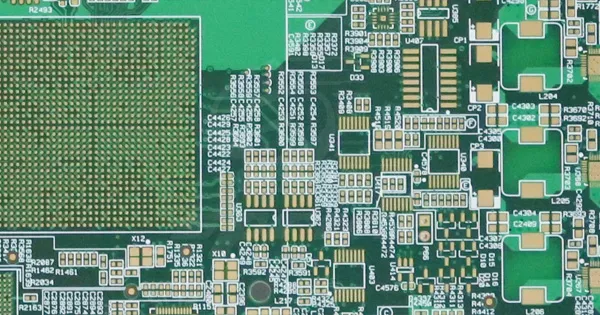

What is a 10 Layer PCB?

A 10 layer PCB is a multilayer printed circuit board that consists of ten conductive layers separated by insulating materials (dielectrics). The layers include signal layers, power planes, and ground planes, interconnected by vias (vertical interconnects). This configuration enables the PCB to handle complex circuitry, high-speed signals, and improved power distribution while maintaining a compact design.

The 10 layer PCB stack-up typically includes the following components:

Signal layers: Where the electrical traces are routed.

Power planes: Responsible for distributing power across the board.

Ground planes: Ensuring that the circuit has a stable reference voltage and reducing electromagnetic interference (EMI).

Key Design Considerations for 10 Layer PCBs

Designing a 10 layer PCB requires careful planning and attention to detail to ensure optimal performance. As a professional 10 layer PCB manufacturer, SprintPCB ensures that our manufacturing process meets all key design requirements. Below are some important design considerations:

Layer Stack-Up Configuration

Choosing the correct layer stack-up is crucial for achieving the desired electrical performance. The configuration of signal, power, and ground planes affects signal integrity, EMI shielding, and overall board performance. In a typical 10 layer PCB stack-up, it is common to place signal layers between power and ground planes to minimize noise and interference.

Via Selection

Vias play an essential role in connecting different layers in the PCB. In a 10 layer PCB, the use of blind, buried, and through-hole vias can optimize the design based on the application’s requirements. Blind vias connect outer layers to inner layers without passing through the entire board, while buried vias connect only inner layers.

Signal Integrity and EMI Control

Signal integrity is one of the most critical design aspects of a 10 layer PCB, especially in high-speed applications. Designers must minimize the signal path length, route differential pairs closely, and use proper impedance control. To control EMI, it’s important to maintain consistent ground planes and avoid crossing signal paths over split planes.

Power Delivery and Grounding

Proper power delivery and grounding are vital for the stability of the circuit. Dedicated power planes are used to distribute power to different components, while solid ground planes ensure minimal voltage drop and EMI suppression. SprintPCB ensures optimal power distribution by carefully managing these planes during manufacturing.

Advantages of 10 Layer PCBs

10 layer PCBs offer several benefits over lower-layer PCBs, making them ideal for applications where performance, reliability, and space are essential. As a trusted 10 layer PCB manufacturer, SprintPCB provides the following advantages in our PCB manufacturing process:

Higher Circuit Density

A 10 layer PCB can accommodate more components and circuitry within a smaller footprint. This is especially beneficial for modern devices that require compact designs without sacrificing performance.

Improved Signal Integrity

With more layers available for routing, signal traces can be better managed, reducing cross-talk and ensuring that signal integrity is maintained in high-frequency applications. This is essential for applications that require precise data transmission, such as in telecommunications or computing.

Better Thermal Management

Multilayer PCBs, including 10 layer PCBs, provide better heat dissipation compared to single or double-layer boards. Additional layers allow for more even heat distribution, preventing hot spots and extending the life of components.

Increased Power Delivery

Having dedicated power and ground planes ensures efficient power delivery to all components, reducing power fluctuations and ensuring the stability of the circuit.

Applications of 10 Layer PCBs

Due to their complexity and versatility, 10 layer PCBs are widely used across various industries. Some of the common applications include:

Telecommunications

In telecom systems, where high-speed data transfer is critical, 10 layer PCBs provide the necessary signal integrity and EMI control to support high-frequency applications.

Aerospace and Defense

The aerospace and defense sectors rely on 10 layer PCBs for their high reliability and ability to handle complex circuits in confined spaces. These PCBs are often used in radar systems, navigation equipment, and communication devices.

Automotive Electronics

As vehicles become smarter with advanced driver-assistance systems (ADAS) and electric vehicle (EV) technologies, 10 layer PCBs are used to handle the sophisticated electronics that power these systems.

Consumer Electronics

From smartphones to gaming consoles, 10 layer PCBs are essential for delivering compact, high-performance devices. The ability to incorporate more functionality in a smaller form factor is key to meeting consumer demands for thinner and lighter devices.

Why Choose SprintPCB as Your 10 Layer PCB Manufacturer?

SprintPCB is a professional 10 layer PCB manufacturer with years of experience in producing high-quality multilayer PCBs for a wide range of industries. Here’s why you should choose us:

Precision Manufacturing

SprintPCB uses advanced equipment and techniques to ensure that every 10 layer PCB is manufactured to the highest standards of quality. Our strict quality control measures guarantee that every board performs reliably.

Customization

We offer thorough design review services, working closely with our clients to ensure their designs are accurately realized. Our manufacturing expertise enables us to tackle sophisticated projects and produce PCBs tailored to your exact needs.

Fast Turnaround

We understand the importance of meeting deadlines. SprintPCB offers fast and efficient production processes without compromising quality, ensuring that your 10 layer PCBs are delivered on time.

Cost-Effective Solutions

As a leading 10 layer PCB manufacturer, SprintPCB offers competitive pricing without sacrificing the quality of our products. Our efficient manufacturing processes allow us to provide affordable solutions to meet your budget.