In the field of PCB assembly, a Bill of Materials (BOM) is a crucial document for ensuring the efficient and smooth production of circuit boards. This article will explain what a BOM is, its importance, the essential contents of a BOM, and tips for creating an effective BOM.

What is a Bill of Materials (BOM)?

A Bill of Materials (BOM) is an indispensable document in the

PCB assembly process. A well-prepared BOM lists all the raw materials, components, precise quantities, part numbers, brand names, and other essential details required. Essentially, a BOM includes a list of components, wires, circuit boards, and circuit requirements. With a BOM, PCBA suppliers can provide clients with an estimated cost for each part and inform them of the procurement time for each component.

The Importance of a BOM

The significance of a BOM in PCB assembly can be highlighted in several ways:

1. Cost Control: A detailed BOM lists all the necessary materials and components, helping PCBA suppliers accurately calculate costs before starting a project. This assists in budget management and can reduce costs through bulk purchasing.

2. Time Management: By clearly listing the procurement time for each component, a BOM helps optimize production schedules, preventing delays caused by part shortages.

3. Quality Assurance: The detailed information in a BOM ensures the use of correct components, avoiding quality issues caused by incorrect parts.

4. Communication Tool: A BOM serves as an essential communication tool between internal teams and clients, ensuring both parties have a consistent understanding of the project requirements and expectations.

What Should a BOM Include?

A BOM should include everything necessary to produce the final product. The information in a BOM varies depending on project requirements. It must be meticulously created to save time, cost, and avoid last-minute confusion. Here are some common categories of information in a BOM:

1. Part Name and Number: To facilitate the identification of required parts, a BOM must list the manufacturer’s part name and number. This helps PCBA suppliers use the correct components. Part numbers are unique identifiers assigned to each part for easy reference and tracking.

2. Description: Each part in the BOM should have an appropriate description, including specifications like voltage, color, size, etc. Detailed information ensures the correct parts are ordered, avoiding unnecessary confusion. Descriptions should also mention measurement units like ohms, ounces, centimeters, and meters.

3. Quantity: Estimate the quantity of each part required for the PCBA, which can help in obtaining bulk purchase discounts.

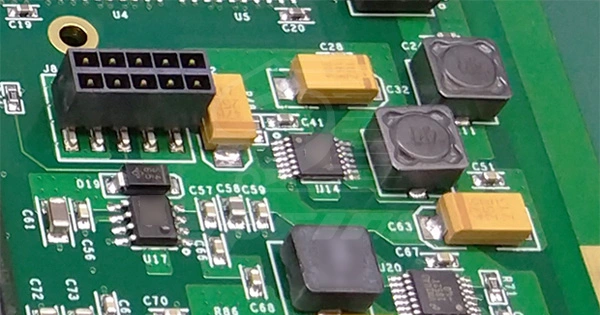

4. Reference Designators: These indicate the placement details of components on the circuit board, with silkscreen labels on the PCB that can quickly identify specific parts during soldering.

5. Manufacturer Name: If a specific brand is sought, the manufacturer’s name must be included. Ensure the availability of the part before listing it. Checking this information in advance can avoid additional costs and time spent sourcing alternative parts during production.

6. Alternative Parts: Listing potential alternative parts in the BOM is crucial. This is helpful if the required part is unavailable or changes occur.

7. Procurement Method: Specify the procurement type in the BOM, indicating whether components are provided by the customer or sourced by PCBA suppliers.

8. BOM Levels: A BOM has multiple levels, each with its unique structure, specifying the ranking of each component to identify all BOM components, whether single-level or multi-level. BOM levels also help users navigate the document and understand the circuit board assembly.

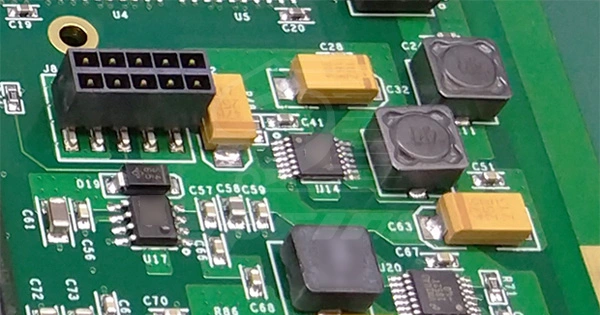

9. Placement Method: Specify the PCB placement method, defining how each part and component will be attached to the board. Placement methods can be through-hole technology, surface mount technology, or a combination of both.

Tips for Creating an Effective BOM

When creating a BOM, there are many considerations. If you’ve never created a BOM before, here are some tips and guidelines to help you start:

1. Include All Details: A BOM is vital for those assembling the PCB. These individuals may never have met you and might not speak the same language. Therefore, the BOM must be as clear, detailed, and accurate as possible. Avoid including too much irrelevant information, as it can cause confusion. Include all useful information in the BOM.

2. Automation: Many companies create BOMs using spreadsheets, which requires manual data entry, is time-consuming, and prone to errors. Nowadays, there are many professional BOM management software tools like Altium Designer, SolidWorks BOM Manager, etc. These tools can help you create and manage BOMs more efficiently, reduce manual input errors, and offer more features like automatic generation of purchase orders, real-time inventory management, and more.

3. Version Control: Ensure the BOM has clear version control. Save a new version each time the BOM is modified and record the reason and details of the modification. This is crucial for tracking historical records and avoiding confusion.

4. Real-Time Updates: During production, the availability and prices of components may change. Update the BOM in real-time to ensure all information is current, avoiding delays and cost increases due to inaccurate information.

5. Supply Chain Management: Maintain close contact with suppliers to ensure a stable supply of key components. Establish multiple supply channels to prevent production disruptions caused by issues with a single supplier.

By following these guidelines and tips, you can create a detailed, accurate, and efficient BOM, ensuring the smooth execution of the PCB assembly process and the high quality of the final product.

---

SprintPCB offers precision PCB Assembly, soldering, product testing, aging, chip programming, connector crimping, ultrasonic welding of plastic housings, laser marking, BGA rework, and more. If needed, please feel free to

contact us.