When modern electronic designs combine high-speed digital processing with RF or microwave communication, choosing the right substrate becomes the determining factor for signal integrity, thermal stability, and overall system performance. A mixed laminate PCB gives engineers a clear advantage by placing each circuit block on the dielectric material that best supports its function—without forcing unnecessary cost into the entire board.

Instead of treating PCB materials as a uniform stack, the mixed laminate approach strategically integrates FR-4 and PTFE/Rogers within a single board, enabling powerful RF behavior and stable digital performance at the same time. This is the reason mixed laminate PCBs have rapidly become the preferred solution for advanced communication devices, radar modules, IoT gateways, and compact RF front-end designs.

Mixed laminate PCBs deliver advantages that go far beyond material theory—they directly solve the most common performance bottlenecks faced by engineers developing compact, mixed-signal systems. When high-speed digital logic and RF circuitry operate within the same device, designers often encounter problems such as excessive insertion loss, unstable impedance, EMI coupling, mechanical failures at interconnects, and unpredictable thermal behavior. A mixed laminate PCB addresses these issues by enabling each part of the system to run on the dielectric substrate optimized for its electrical profile.

One of the most impactful improvements introduced by mixed laminate PCBs is the dramatic enhancement in RF signal integrity. Traditional FR-4 materials exhibit high dielectric loss, which degrades gain, distorts phase response, and restricts operational bandwidth.

By routing RF transmission lines, antennas, matching networks, and microwave components onto PTFE-based or Rogers high-performance layers, engineers gain:

Lower insertion loss along high-frequency paths

More predictable impedance even at multi-GHz frequencies

Excellent phase stability, which preserves modulation accuracy

Higher receiver sensitivity and transmit efficiency

These benefits are particularly critical for 5G communication modules, radar sensing platforms, satellite signal receivers, and precision RF measurement systems. Mixed laminate PCBs ensure that RF stages operate under conditions optimized for low-loss propagation, enabling cleaner channels and more reliable wireless performance.

While RF performance benefits from premium high-frequency substrates, digital sections typically operate best on rigid, cost-efficient FR-4 layers. Mixed laminate PCBs allow each domain to use its ideal material without compromising the other.

High-speed buses such as PCIe, LVDS, SERDES, USB 3.x, and DDR memory interfaces benefit from:

Improved mechanical rigidity, which strengthens solder joints

Consistent dielectric behavior, stabilizing timing-critical paths

Stackup-based isolation, preventing switching noise from leaking into RF domains

The result is:

Reduced jitter in high-speed interfaces

Stronger timing margins

Cleaner and more symmetrical eye diagrams

Fewer signal-integrity-related failures during compliance testing

This coexistence of optimized materials within one board significantly improves the predictability and reliability of digital circuits in mixed-signal designs.

A major real-world advantage of mixed laminate PCBs is system-level consolidation. Many traditional designs separate RF circuits from digital or power sections, requiring coaxial jumpers, interposers, mezzanine connectors, or separate modules.

These interconnects often introduce:

Insertion loss and impedance discontinuities

Mechanical weak points that fail under vibration

Increased assembly steps and higher manufacturing cost

By integrating RF, digital, control, and power subsystems onto a single mixed laminate PCB, engineers can:

Shorten electrical paths, improving signal quality

Remove fragile connectors, boosting mechanical robustness

Simplify assembly, reducing labor and alignment tolerance issues

Enable more compact final products without sacrificing performance

This approach is especially beneficial in IoT modules, automotive radar assemblies, wireless gateways, and precision sensor devices where reliability and small size are essential.

Mixed dielectric stackups also help engineers achieve stronger EMC/EMI performance without relying solely on external shielding enclosures. The ability to mix materials with different permittivity and loss characteristics provides unique control over signal return paths and field distribution.

Well-designed mixed laminate PCBs offer:

Cleaner ground reference planes, reducing loop noise

Localized isolation regions, preventing digital noise from coupling into RF chains

Controlled impedance transitions, lowering reflection and radiated emissions

More predictable current loops, reducing electromagnetic leakage

These improvements directly support regulatory compliance for CE, FCC, and automotive EMC standards.

In practical engineering environments, the advantages of mixed laminate PCBs translate directly into measurable results:

Higher system throughput from improved signal integrity

Longer RF communication range due to lower dielectric losses

Lower failure rate from both electrical and mechanical improvements

More stable thermal behavior, especially where power and RF coexist

Reduced total cost of ownership, thanks to simplified assembly and better long-term reliability

This combination of electrical, mechanical, and economic benefits is exactly what product teams, engineering managers, and procurement officers value when selecting PCB technologies for next-generation hardware.

5G hardware integrates multiple high-frequency chains—sub-6 GHz and mmWave—alongside powerful baseband processors and memory. Mixed laminate PCB boards allow these devices to place RF layers on ultra-low-loss Rogers/PTFE substrates while hosting digital logic on FR-4.

This provides:

Higher antenna efficiency for better link quality

Cleaner PA/LNA behavior for extended range

Reduced internal interference between RF chains

Smaller enclosure sizes, ideal for CPE, indoor units, and portable hotspots

The result is faster throughput, better coverage, and more energy-efficient 5G equipment.

Modern vehicles rely on 24 GHz and 77 GHz radar systems for ADAS functions like blind-spot detection, adaptive cruise control, and collision avoidance. These systems require extremely stable RF behavior, even in harsh temperature environments.

Mixed laminate PCBs support:

Ultra-low-loss RF propagation on radar front-end layers

Digital signal processors and microcontrollers on FR-4 layers

High thermal stability to withstand under-hood conditions

Improved cost efficiency for large-scale automotive production

The hybrid-material stackup ensures consistent detection accuracy, lower phase noise, and stable range performance across a wide temperature band.

GNSS modules must handle extremely weak satellite signals. Even small amounts of dielectric loss or noise coupling can dramatically reduce sensitivity.

Mixed laminate PCBs benefit GNSS systems by offering:

Low-noise RF paths on Rogers/PTFE

Stable filter characteristics for precise frequency selection

FR-4 layers for digital correlation engines, algorithms, and power management

Compact form factor suitable for handhelds, drones, and vehicle tracking units

This hybrid approach delivers cleaner LNA performance, better acquisition speed, and more reliable satellite tracking.

IoT gateways often integrate several radios—Wi-Fi, Bluetooth, Zigbee, Sub-GHz, and cellular. These radios must coexist in extremely limited PCB space.

Mixed laminate PCBs allow:

Each radio band to operate on a proper low-loss substrate

Digital processors, edge-compute modules, and memory to remain on FR-4

Better isolation between radios, improving coexistence performance

Lower interference and cleaner modulation paths

This enhances wireless stability, range, and reliability in industrial IoT, smart home devices, and battery-powered terminals.

Microwave modules require stringent dielectric performance to maintain gain, linearity, and low distortion.

Mixed laminate PCBs enable:

Precision routing for LNAs, PAs, filters, or couplers

Robust thermal paths for high-power amplification

Predictable RF performance across frequency and temperature

Lower overall module cost compared with full-Rogers PCBs

This makes hybrid-material PCBs ideal for radar, SATCOM, RF instrumentation, and aerospace communication equipment.

Devices such as drones, portable test equipment, medical instruments, and industrial controllers must pack multiple functions into a very small footprint.

Mixed laminate PCBs provide:

Dense high-speed digital routing

RF antenna sections and connectivity modules

Compact stackups with reduced interconnect length

Better battery efficiency through optimized RF paths

The result is lightweight, agile, and highly integrated products.

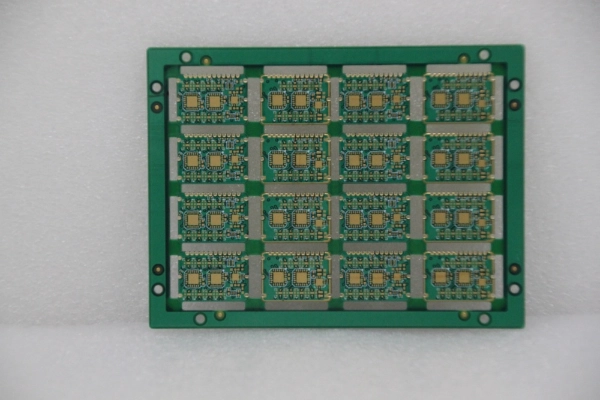

SprintPCB provides mixed laminate PCB manufacturing that focuses specifically on high-frequency stability and controlled-impedance routing, using FR-4 and Rogers materials. Their process emphasizes:

Precise layer bonding between FR-4 and Rogers

Stable drilling and plating for 0.15 mm mechanical vias

Fine-line capability at 0.075 mm / 0.075 mm

Surface finishes such as ENIG and Immersion Silver for RF signal quality

For engineers seeking a supplier capable of reliable hybrid FR-4/Rogers stackups, SprintPCB mixed laminate PCB offers a practical, production-ready option without inflating project cost.

A mixed laminate PCB provides what single-material PCBs cannot: targeted high-frequency performance paired with cost-efficient digital routing, all in one compact architecture. By combining PTFE/Rogers only where low-loss behavior is required and using FR-4 for the remaining layers, the design achieves an ideal balance of electrical performance, structural stability, and manufacturing cost.

For engineering teams looking to enhance RF performance without unnecessary expense—and without splitting circuits across multiple boards—a mixed laminate PCB is the most effective and mature solution.

Customer support