In the evolving world of electronics, the demands for smaller, more reliable, and efficient devices have never been higher. Wearable technology and IoT (Internet of Things) products, in particular, are at the forefront of this evolution, pushing the boundaries of design and functionality. One key innovation that is rapidly gaining traction in these industries is rigid-flex PCB technology. In this article, SprintPCB will explore why Rigid-Flex PCB is becoming a critical component for the next generation of wearable and IoT devices and why it is likely to play a central role in future product designs.

Rigid-Flex PCBs offer numerous advantages, particularly when it comes to designing wearables and IoT devices. These benefits include:

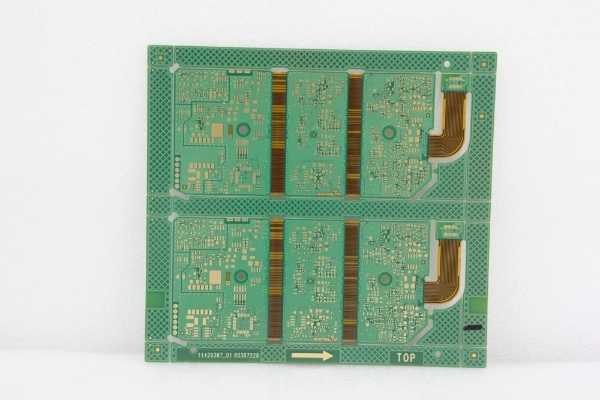

One of the most significant challenges in wearable and IoT device design is maximizing space efficiency. Devices like smartwatches, fitness trackers, and other compact wearables require PCBs that can fit into tight spaces without compromising functionality. Rigid-flex PCBs are ideal for this purpose because they allow designers to incorporate both rigid and flexible components into the same board. The flexible sections of the PCB can be bent or folded to fit around small spaces or components, while the rigid sections maintain the necessary support and stability.

For IoT devices, which often need to be embedded in various environments, the ability to create a compact and flexible design is invaluable. Rigid-Flex PCBs can be used to reduce the overall size of the device while maintaining or even improving its performance.

Wearables, especially fitness trackers and medical devices, are subjected to constant movement, flexing, and even exposure to harsh environmental conditions. A traditional rigid PCB can break or fail under stress, which is why the flexible nature of Rigid-Flex PCBs is so beneficial. The flexibility of the board ensures that it can withstand bending and twisting without damaging the electrical components, providing greater durability in applications that involve frequent movement or physical stress.

In addition, Rigid-Flex PCBs are typically more resistant to shock, vibration, and impact, making them ideal for IoT devices used in rugged environments such as industrial monitoring systems or outdoor sensors.

Weight is another crucial factor in wearable devices, where comfort is essential. A heavy device can be uncomfortable and impractical for daily use. By incorporating flexible sections into the design, Rigid-Flex PCBs help reduce the overall weight of the device. Flexible PCBs are thinner and lighter than traditional rigid PCBs, which directly translates to a more comfortable user experience without sacrificing performance.

For IoT devices that need to be deployed in remote or difficult-to-reach areas, reducing the weight of the device can also make installation and handling much easier.

Signal integrity is critical in wearable and IoT devices, where seamless communication between sensors, components, and external networks is necessary. Rigid-Flex PCBs help reduce the potential for signal degradation by minimizing the number of interconnections between different circuit board layers. With fewer connections and vias (holes used to connect different layers), the risk of signal loss is reduced, ensuring that the device operates more efficiently and reliably.

This is especially important for IoT devices that rely on continuous data transmission, such as smart home systems or industrial IoT sensors. High-quality signal integrity ensures that these devices function optimally, even in environments with potential interference or signal disruptions.

While the initial cost of producing Rigid-Flex PCBs may be higher compared to traditional rigid PCBs, they can provide significant cost savings in the long run, particularly for high-volume production. By combining the rigid and flexible elements into a single PCB, manufacturers can reduce the need for multiple PCBs, connectors, and assembly processes. This leads to fewer parts, less complexity, and a streamlined manufacturing process, which can ultimately lower the overall cost of production.

For wearable and IoT product manufacturers, this is a critical consideration, as high-volume production is often necessary to meet market demand. Rigid-Flex PCBs provide an efficient and cost-effective solution without sacrificing quality or performance.

Rigid-Flex PCBs offer enhanced reliability due to their robust design. The flexibility of the PCB reduces the risk of fatigue or failure due to mechanical stress, which is common in traditional rigid PCBs. This improved reliability is particularly important for wearables and IoT devices that require long-term operation without maintenance.

Moreover, the compact nature of Rigid-Flex PCBs reduces the need for connectors and cables, which can wear out over time. This results in fewer points of failure and a longer lifespan for the device.

Wearable health devices such as fitness trackers, smartwatches, and health monitoring systems require small, durable, and reliable PCBs. These devices often include sensors, communication modules, and power sources, all of which need to be integrated into a compact and flexible design. Rigid-Flex PCBs are the ideal solution, offering the necessary space efficiency, flexibility, and durability.

As augmented reality continues to evolve, devices like smart glasses are becoming more mainstream. These devices require complex PCBs that integrate various components, such as displays, sensors, and communication systems, into a small, lightweight package. The flexibility of rigid-flex PCBs allows for a design that fits comfortably into the frame of the glasses while maintaining performance and durability.

IoT devices, such as smart thermostats, security cameras, and environmental sensors, often need to be small, durable, and reliable. Rigid-Flex PCBs are an excellent choice for these devices, as they allow for efficient use of space while ensuring the integrity of the signal and reducing the likelihood of failure. These advantages are critical in IoT applications where devices are often deployed in remote or challenging environments.

In the automotive and industrial sectors, IoT devices are increasingly used to monitor equipment, track performance, and collect data in real-time. These devices need to be robust and able to withstand harsh conditions, such as high temperatures, vibration, and exposure to chemicals. Rigid-Flex PCBs offer the necessary durability and reliability for such applications, ensuring the long-term performance of these critical systems.

As the demand for wearables and IoT devices continues to grow, SprintPCB stands out as a leading provider of high-quality Rigid-Flex PCBs. With extensive expertise in advanced PCB manufacturing, SprintPCB offers multi-layer PCBs, HDI PCBs, high-frequency PCBs, and Rigid-Flex PCBs that are designed to meet the specific needs of each client. The company's commitment to providing a one-stop solution—from manufacturing to assembly—ensures that clients can bring their products to market quickly and efficiently.

SprintPCB's state-of-the-art facilities and dedication to quality make it the ideal partner for companies seeking to develop the next generation of wearable and IoT products. Whether you are looking for prototypes, small-volume runs, or large-scale production, SprintPCB offers the flexibility, reliability, and technical expertise required for success in today's competitive electronics market.

Rigid-flex PCB boards are the future of wearable and IoT product design due to their unique combination of flexibility, durability, and performance. These PCBs provide manufacturers with the ability to create compact, lightweight, and highly reliable devices that meet the increasing demands of modern consumers. From wearable health devices to industrial IoT sensors, Rigid-Flex PCBs offer unparalleled advantages, making them a critical technology for the next generation of electronic products.

As a leading provider of high-tech PCBs, SprintPCB is at the forefront of this innovation, offering state-of-the-art solutions that meet the specific needs of the wearable and IoT industries. With their expertise in Rigid-Flex PCB manufacturing, SprintPCB is well-positioned to help companies develop the cutting-edge products of tomorrow.

For companies looking to stay ahead in the rapidly evolving electronics market, embracing Rigid-Flex PCBs is not just an option—it's a necessity.

Customer support