In the fast-evolving automotive industry, the demand for innovative technologies has never been higher. With the shift towards electric vehicles (EVs), hybrid electric vehicles (HEVs), and the continuous need for enhanced safety and energy efficiency, automotive manufacturers are increasingly turning to advanced solutions. One such solution that has proven essential is the use of thick copper printed circuit boards (PCBs). These specialized PCBs provide exceptional power management, thermal dissipation, and reliability, making them a cornerstone of modern automotive electronics. SprintPCB thick copper PCBs, which can handle copper weights up to 6 ounces, are designed specifically to meet the stringent demands of the automotive sector.

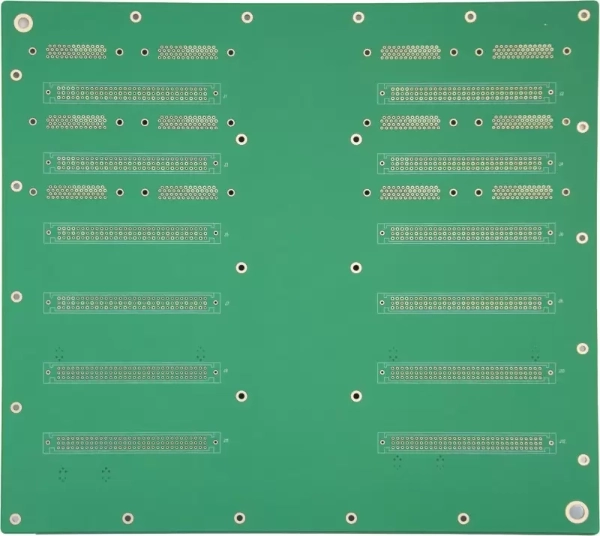

Thick copper PCBs are specialized circuit boards that utilize copper layers thicker than the standard 1 ounce per square foot. Typically, these PCBs feature copper weights of 2 ounces or more, with some reaching up to 6 ounces per square foot. This thicker copper allows for better current-carrying capacity, higher power handling, and superior thermal management, all crucial for applications that require high-performance electronics. While traditional PCBs are typically used for lower-power applications, thick copper PCBs are designed to handle the heavy power demands of automotive systems, especially in electric vehicles, battery management, and power electronics.

Unlike standard PCBs, thick copper PCBs provide more efficient power distribution and can handle larger amounts of current without overheating. This is particularly important in automotive systems, where power electronics need to operate under heavy loads for extended periods. The increased copper thickness ensures that the PCB can manage these demands without risking failure due to excessive heat or electrical strain. SprintPCB thick copper PCBs are crafted with advanced manufacturing techniques to ensure high performance and long-term reliability, making them perfect for automotive applications.

Automotive applications demand reliability, durability, and efficiency. SprintPCB specializes in manufacturing thick copper PCBs with copper weights as high as 6 ounces, which is particularly beneficial in electric vehicles (EVs), hybrid vehicles, and automotive power management systems. SprintPCB's advanced etching, plating, and lamination processes ensure outstanding current-carrying capacity, heat dissipation, and long-term reliability, even in the most demanding environments.

Automotive systems, particularly in electric vehicles and hybrid cars, rely on power-intensive components that demand superior current capacity. SprintPCB thick copper PCBs are designed to handle high currents, capable of carrying several amperes of electrical current without compromising performance. This makes them an ideal choice for applications such as motor control, battery management systems (BMS), and power conversion circuits. As automotive technology continues to push the boundaries of performance, SprintPCB thick copper PCBs ensure that these high-power systems are supported by reliable, efficient, and robust PCBs that can withstand the continuous flow of electricity.

In EVs, where power management is crucial for both motor efficiency and battery life, thick copper PCBs are essential for maintaining consistent performance while ensuring the safety and longevity of high-power circuits. By providing reliable current distribution, these PCBs minimize the risks of voltage drops or power loss, which can affect the performance of key automotive systems.

Efficient thermal management is a cornerstone of automotive electronic design. In automotive applications, heat dissipation is a critical issue, especially in high-power components such as inverters, motor controllers, and power distribution units. SprintPCB thick copper PCBs excel in thermal conductivity, making them an ideal solution for managing the heat generated by these components. The high copper content allows for better heat distribution, preventing hotspots and reducing the risk of overheating, which could lead to component failure or even safety hazards.

In environments where temperatures fluctuate drastically, especially in electric vehicles that often experience high current draw, thick copper PCBs ensure that the systems stay within safe operating temperatures. This capability is especially important in automotive power management systems, where maintaining consistent temperature levels is essential for the protection of delicate components. SprintPCB thick copper PCBs provide enhanced thermal stability, ensuring that automotive systems remain efficient and safe under even the most demanding conditions.

The automotive industry operates in some of the most challenging environments, where components are exposed to extreme temperatures, vibrations, and mechanical stress. SprintPCB thick copper PCBs are engineered to perform reliably under these harsh conditions. They offer excellent mechanical strength and are resistant to the stresses that automotive components typically experience during operation. Whether it's the vibrations caused by engine performance or exposure to high and low temperatures, thick copper PCBs are designed to maintain their integrity and functionality.

For electric vehicles, which operate in a variety of climates and environmental conditions, reliability is paramount. The systems inside EVs, from battery management to motor control circuits, must perform flawlessly in all conditions, from freezing cold to intense heat. SprintPCB thick copper PCBs are engineered to handle these conditions, providing long-lasting performance and reducing the likelihood of system failures. The robustness of these PCBs ensures that they stand up to wear and tear over time, making them a trusted choice for the automotive industry.

Thick copper PCBs are an essential component in the design and manufacturing of automotive electronics, particularly in electric and hybrid vehicles. SprintPCB thick copper PCBs offer superior thermal management, high current-carrying capacity, and long-term reliability, making them the ideal choice for power electronics, motor controllers, and industrial equipment in the automotive industry. With their advanced manufacturing techniques and commitment to quality, SprintPCB is paving the way for the next generation of automotive technologies, helping automakers achieve greater efficiency, performance, and reliability in their vehicles.

Customer support