Printed Circuit Boards (PCBs) are the backbone of modern electronics, enabling the seamless integration of components into devices that power our everyday lives. From smartphones and medical devices to automotive systems and aerospace technologies, reliable PCB solutions ensure functionality, performance, and safety. While standard PCBs may suit basic needs, advanced applications demand something more specialized—custom PCB manufacturing.

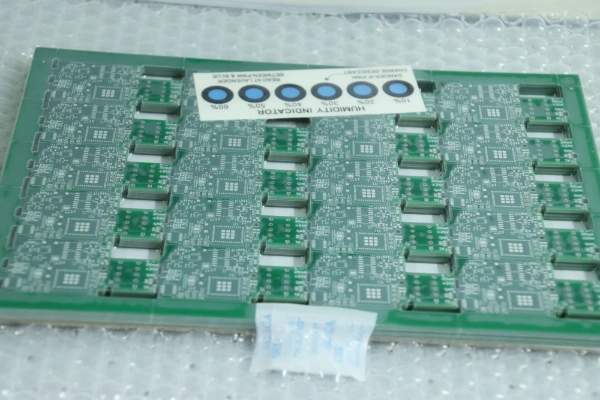

Custom PCB manufacturing allows companies to design and produce boards tailored precisely to their requirements, ensuring superior performance, flexibility, and efficiency. SprintPCB, a trusted industry leader, specializes in small- and medium-batch PCB production, PCB assembly, and end-to-end electronic manufacturing services (EMS). With cutting-edge facilities, a team of experienced engineers, and a customer-focused approach, SprintPCB transforms complex designs into reliable, high-quality PCBs ready for use in real-world applications.

In today's fast-evolving electronics industry, every product carries its own set of electrical, mechanical, and environmental demands. A standardized circuit board may be sufficient for very basic applications, but when dealing with modern high-performance devices, generic solutions often fail to meet the mark. This is where custom PCB manufacturing becomes essential. It ensures that the final design is executed precisely, performs reliably even in harsh environments, and can scale smoothly from initial prototypes to full-scale production.

One of the greatest advantages of custom PCB manufacturing is the ability to create highly optimized layouts. Custom boards are engineered with exact signal paths, thermal management strategies, and material choices that support consistent performance. This precision allows designers to minimize interference, reduce noise, and manage heat dissipation effectively—qualities that are critical for devices that must run continuously or operate under high loads.

Unlike generic boards, custom PCBs are designed with the specific end-use in mind. A medical imaging system, a wearable health tracker, and an automotive control unit all require very different board architectures. Through custom PCB manufacturing, companies can tailor designs to optimize for size, functionality, durability, or regulatory compliance. This application-driven approach ensures that products not only function properly but also excel in their intended environments.

Another key benefit of custom PCB manufacturing is scalability. Businesses can start with small prototype batches to validate their designs, refine layouts, and test performance under real-world conditions. Once finalized, the design can be seamlessly scaled into medium or large production volumes, maintaining consistent quality and reliability at every stage. This smooth transition helps companies bring products to market faster while controlling costs.

Material choice and layering options are also critical in achieving optimal results. With custom PCB manufacturing, businesses can select substrates, copper thicknesses, surface finishes, and layer counts that best suit their application. For example, high-frequency communication equipment may require specialized laminates, while rugged industrial equipment may benefit from thicker copper and reinforced finishes. This flexibility ensures that every board is designed to balance performance, cost, and durability.

Selecting the right partner for custom PCB manufacturing is one of the most important decisions a business can make when developing electronic products. A reliable manufacturer not only delivers high-quality boards but also provides the technical expertise and service support needed to bring complex designs into reality. SprintPCB has earned its reputation as a trusted partner by combining advanced production capabilities with customer-focused services, ensuring that every project—from prototype to large-scale production—runs smoothly and efficiently.

SprintPCB's strength in custom PCB manufacturing lies in its ability to handle a wide variety of board types, including multilayer PCBs, HDI PCBs, high frequency PCBs, mixed laminate PCBs, rigid flex PCBs, flexible PCBs, double sided PCBs, and metallized half-hole PCBs. This extensive portfolio enables SprintPCB to serve industries as diverse as automotive, medical, aerospace, and telecommunications. Whatever the complexity of the application, SprintPCB ensures that the final product meets strict electrical, thermal, and mechanical requirements.

A key element of successful custom PCB manufacturing is careful engineering support at the earliest stages of a project. SprintPCB provides proactive services such as DFM guidance, optimized material selection, and cost-saving recommendations that help clients avoid errors and reduce production costs. By reviewing and refining design files before fabrication, SprintPCB ensures that each board is manufacturable, reliable, and tailored to the client's performance goals.

Custom PCB manufacturing does not end with board fabrication—assembly is equally critical. SprintPCB offers integrated assembly services that include stencil production, component sourcing, SMT and through-hole assembly, as well as IC programming and functional testing. By combining fabrication and assembly under one roof, SprintPCB shortens lead times, reduces supply chain risks, and ensures that customers receive complete, production-ready solutions.

In fields such as automotive, medical, and aerospace, custom PCB manufacturing requires compliance with the strictest international standards. SprintPCB's certifications, including ISO 9001, RoHS, UL, IATF 16949, ISO 13485, AS9100, and QC080000, guarantee that every board is produced under rigorous quality control. These certifications are proof of SprintPCB's ability to deliver safe, reliable, and industry-compliant products that perform consistently under demanding conditions.

Another reason SprintPCB is a leader in custom PCB manufacturing is its dedication to personalized service. Clients benefit from dedicated account managers, transparent and fast quotations, order tracking with regular updates, and flexible pricing and delivery solutions. This customer-first approach ensures that every project receives the attention it deserves and that communication remains clear and responsive throughout the entire process.

True partnership in custom PCB manufacturing goes beyond delivery. SprintPCB offers responsive after-sales support with quick complaint handling, detailed 8D reporting, and collaborative problem-solving. This ongoing accountability strengthens client trust and ensures that any issues are resolved effectively, protecting both product reliability and customer satisfaction.

Finally, SprintPCB's expertise in custom PCB manufacturing extends to safe and efficient logistics. From multiple shipping options and protective anti-static packaging to custom labeling and scheduled deliveries, SprintPCB ensures that products arrive on time and in perfect condition. This flexibility is especially valuable for international customers with complex shipping requirements.

Custom PCB manufacturing is the cornerstone of innovation in today's fast-paced electronics industry. By choosing SprintPCB, companies gain access to advanced manufacturing technologies, certified quality systems, comprehensive assembly services, and personalized customer support. Whether you need prototypes, small batches, or medium-volume production, SprintPCB delivers with speed, accuracy, and reliability.

For businesses seeking a partner that offers more than just PCB fabrication—one that provides engineering guidance, flexible logistics, and ongoing support—SprintPCB is the clear choice. With expertise across multilayer PCBs, HDI PCBs, high frequency PCBs, rigid flex PCBs, and flexible PCBs, SprintPCB ensures that your designs are transformed into real-world solutions with precision and care.

Ready to bring your designs to life? Contact SprintPCB to learn how their team can support your next project.

Customer support