As industries evolve and demand increasingly compact, efficient, and reliable electronic components, flexible PCBs (Printed Circuit Boards) have emerged as a pivotal solution. Unlike traditional rigid PCBs, flexible PCBs can bend, twist, and conform to various shapes, offering significant advantages in applications where space constraints and dynamic motion are critical. Whether in automotive electronics, medical devices, or industrial machinery, flexible PCBs are revolutionizing how modern electronic systems are designed and implemented.This article explores their advantages and SprintPCB flexible PCB specifications.

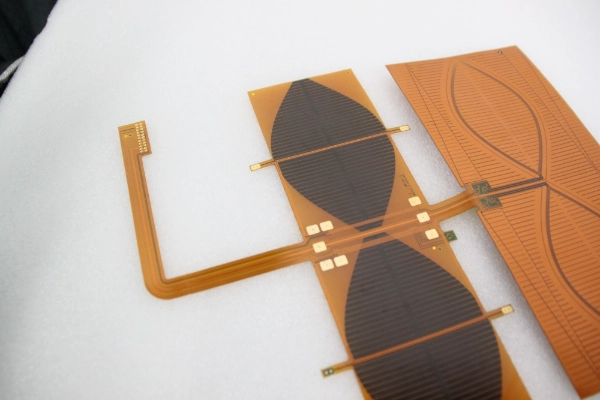

A flexible PCB is an electronic circuit made on a flexible substrate such as polyimide or polyester. Unlike traditional rigid PCBs, flexible PCBs can bend, fold, and stretch without compromising their electrical properties. This flexibility allows for greater design freedom, enabling the creation of smaller and more compact electronic devices.

Flexible PCBs are constructed with the same principles as rigid PCBs, but the base material is chosen specifically for its ability to bend and maintain electrical performance over time. This unique characteristic makes flexible PCBs an excellent choice for applications where traditional rigid boards would fail due to space constraints or environmental conditions that involve bending or movement.

One of the most significant advantages of flexible PCBs is their ability to save space in electronic systems. Their lightweight and flexible nature allow them to conform to irregular shapes and fit into tight spaces that would be impossible for traditional rigid PCBs. This feature is especially beneficial in industries such as automotive and medical, where compact and efficient designs are crucial for optimal performance and functionality.

The use of flexible PCBs reduces the need for bulky connectors and wiring, enabling manufacturers to create more streamlined designs that are both compact and high-performing.

The ability of flexible PCBs to bend and withstand mechanical stress without losing their functionality makes them ideal for environments that require high reliability. Whether it's exposure to vibrations, thermal stress, or constant movement, flexible PCBs are designed to maintain their integrity even in the most demanding conditions.

For example, in automotive applications where the system is exposed to vibrations and temperature fluctuations, flexible PCBs provide enhanced reliability and longevity. Their resistance to mechanical wear and tear ensures that the devices continue to function without degradation, even over extended periods of use.

Heat dissipation is a critical aspect of electronic design, especially in high-performance applications. Flexible PCBs offer excellent thermal conductivity, ensuring that heat is distributed more evenly across the board. This feature helps prevent overheating and extends the lifespan of the electronic components.

By allowing for more effective heat dissipation, flexible PCBs contribute to better overall system performance, reducing the likelihood of thermal damage and enhancing reliability in environments subject to fluctuating temperatures.

While the initial cost of flexible PCBs may be higher than traditional PCBs, the long-term benefits make them a cost-effective solution. By reducing the need for connectors, cables, and other components, flexible PCBs help lower both material and assembly costs. Additionally, their compact design allows for smaller, lighter devices, which can further reduce transportation and storage costs.

In many cases, flexible PCBs can streamline the manufacturing process and reduce the overall complexity of circuit design, providing cost savings in the long run.

When selecting flexible PCBs for your project, it's important to consider the technical specifications to ensure the PCB meets your requirements. SprintPCB offers flexible PCBs with the following key features:

Layer Count: 1-6 layers, providing flexibility in both design and performance.

Materials: Polyimide and polyester substrates, known for their excellent flexibility, durability, and thermal stability.

Profile Method: Laser cutting, punching, and milling ensure precision and minimal burr formation for high-quality products.

Copper Thickness: 8 µm to 70 µm, offering a wide range of current-carrying capacities.

Thickness: 0.05 mm to 0.80 mm, providing flexibility for a variety of applications.

Maximum Size: 250 mm x 610 mm, suitable for both small and medium-sized designs.

Minimum Track and Gap: 0.05 mm / 0.05 mm for fine-pitch applications.

Surface Treatments Available: Options include HASL, LF HASL, OSP, ENIG, tin, silver, and gold finger, allowing for the perfect finish for each application.

Flexible PCBs are a game-changer in the world of electronics, offering superior flexibility, reliability, and performance in applications where traditional rigid boards would fail. From automotive systems and medical devices to industrial machinery, flexible PCBs are becoming the go-to solution for compact, high-performance designs.

By choosing SprintPCB flexible PCBs, you are ensuring that your products are built to last, with the durability, heat dissipation, and flexibility necessary for optimal performance. With a wide range of customizable options, superior materials, and high-quality manufacturing processes, SprintPCB provides the ideal solution for all your flexible PCB needs.

Customer support