The electronic industry is evolving at a rapid pace, with demands for faster data transfer, lower signal loss, and more efficient thermal management becoming essential across all sectors. Whether it s 5G infrastructure, aerospace avionics, or automotive radar, the printed circuit board (PCB) is the foundation that determines system performance. Standard PCBs made solely of FR4 can no longer keep up with these advanced requirements, especially when circuits need to operate at gigahertz frequencies or in environments with extreme thermal cycling.

This is where mixed laminate multilayer PCB solutions come into play. Instead of relying on a single dielectric material, this technology combines multiple laminates—such as FR4, Rogers, and PTFE—into one integrated board structure. By carefully layering different substrates in one stack-up, engineers can achieve signal integrity, thermal stability, and cost efficiency all in a single solution. At SprintPCB, our expertise in mixed laminate multilayer PCB manufacturing ensures that customers receive boards optimized for both performance and reliability, supported by precise lamination control and material-matching techniques.

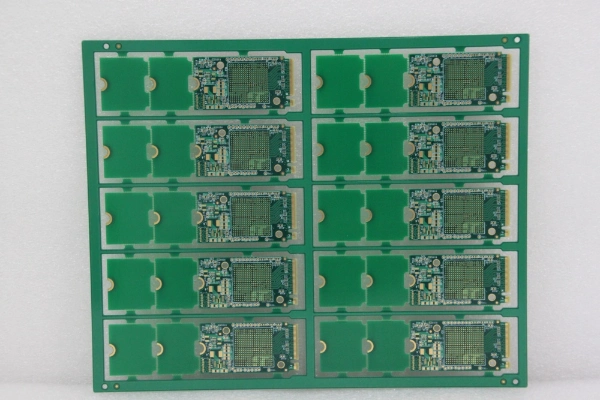

A mixed laminate multilayer PCB is a type of circuit board that incorporates more than one dielectric material in its layer stack-up. Instead of using FR4 throughout the entire PCB, designers strategically combine high-performance laminates like PTFE or Rogers in areas where high-frequency and low-loss performance is critical, while retaining cost-effective FR4 in less demanding sections. This results in a PCB that is optimized for multiple applications within the same board, making it highly versatile.

For example, in a design where both RF circuitry and high-speed digital signals coexist, PTFE or Rogers laminates can be positioned under the RF paths to minimize dielectric losses and ensure stable impedance, while FR4 layers can support digital or power circuits without adding unnecessary cost. This careful material distribution is the hallmark of mixed laminate multilayer PCB engineering, enabling one board to deliver the benefits of multiple substrates without sacrificing manufacturability or scalability. SprintPCB has perfected this integration process, ensuring smooth adhesion between dissimilar laminates and consistent electrical performance across the entire stack-up.

Conventional multilayer PCBs built entirely with FR4 remain reliable for many general applications, but they quickly reach their limits in high-frequency, high-speed, and thermally demanding environments. This is why more engineers and product developers are now turning to SprintPCB mixed laminate multilayer PCB solutions. By strategically combining FR4 with premium laminates such as PTFE and Rogers, SprintPCB provides boards that balance signal integrity, thermal reliability, and cost efficiency in ways that traditional FR4-only PCBs cannot achieve.

One of the standout benefits of a SprintPCB mixed laminate multilayer PCB is its ability to preserve signal integrity at very high frequencies. FR4-only structures introduce attenuation and impedance variation, which can degrade performance in data-heavy environments. SprintPCB integrates low-loss materials like PTFE and Rogers exactly where they are needed, ensuring clean signal transmission and stable impedance. This makes the boards particularly suitable for 5G base stations, aerospace radar, and data center servers where gigahertz-level frequencies demand flawless performance.

Heat management is another area where the SprintPCB mixed laminate multilayer PCB demonstrates clear advantages. Traditional FR4 lacks the thermal stability needed for high-power systems, which can result in warpage or shifts in electrical properties under load. SprintPCB addresses this by incorporating laminates with superior heat conductivity and dimensional stability, producing boards that maintain consistent electrical performance even under sustained stress. This ensures that devices such as EV power modules or RF amplifiers operate reliably in the field.

Premium laminates are expensive, but a SprintPCB mixed laminate multilayer PCB is designed to balance cost and performance intelligently. Instead of using costly materials across the entire stack-up, SprintPCB engineers apply them selectively—only in high-frequency or thermally sensitive layers—while relying on FR4 for supporting sections. This hybrid strategy delivers top-tier performance where it matters most while controlling overall costs, making it ideal for projects where budget constraints are as important as technical performance.

The SprintPCB mixed laminate multilayer PCB also offers unmatched design flexibility. Many modern systems must combine RF circuits, high-speed digital processors, and power management units into one compact board. With FR4-only designs, this often leads to compromises in layout or performance. SprintPCB 's hybrid material approach allows each signal domain to be optimized within the same PCB stack-up, reducing size, simplifying assembly, and improving overall reliability. For complex designs that require multiple functionalities on a single board, this flexibility is invaluable.

Ultimately, the SprintPCB mixed laminate multilayer PCB represents a balanced solution for today 's demanding applications. By integrating diverse laminates with precision and engineering expertise, SprintPCB enables customers to achieve the best possible combination of performance, reliability, and cost control. For industries such as telecommunications, aerospace, automotive, and medical devices, this technology provides the foundation for products that outperform conventional PCB designs.

The future of electronics depends on high-speed, high-frequency, and thermally efficient circuit designs. A mixed laminate multilayer PCB is not just a cost-effective solution—it is the enabling technology behind 5G, aerospace radar, EVs, and advanced medical devices.

With SprintPCB 's expertise in material integration, lamination precision, and scalable manufacturing, customers gain more than just a supplier—they gain a long-term partner for innovation. From prototype to mass production, our focus remains on quality, reliability, and performance.

Customer support