Ceramic PCBs, also known as ceramic substrates or ceramic-coated boards, are different from traditional PCBs made of organic materials such as fiberglass and epoxy resin. Ceramic PCBs are produced by bonding copper foil directly onto a substrate made of ceramic materials like aluminum oxide (Al₂O₃), aluminum nitride (AlN), or others through a process called Direct Bonded Copper (DBC). This high-temperature sintering process fuses the copper foil with the ceramic substrate, creating a board with excellent electrical insulation and thermal conductivity. Ceramic PCBs can be etched like traditional PCBs to form complex circuit patterns with good current-carrying capabilities, making them ideal for high-power electronic applications.

Common Ceramic Substrate Materials

The performance of ceramic PCBs largely depends on the substrate material used. Different ceramic materials offer distinct characteristics in terms of thermal, electrical, and mechanical properties. Below are detailed descriptions of some common ceramic substrate materials:

Aluminum Oxide (Al₂O₃)

Aluminum oxide is the most commonly used ceramic substrate material due to its good thermal conductivity, mechanical strength, and electrical insulation properties. It is widely used in power electronics, LED cooling, and microwave communications due to its abundant availability and moderate cost. Aluminum oxide ceramics are available in different grades based on purity (75%, 96%, and 99.5% purity). While the variation in aluminum oxide content does not significantly affect its electrical properties, it greatly influences its mechanical performance and thermal conductivity. High-purity aluminum oxide substrates are denser, have lower dielectric loss, and better surface smoothness, making them suitable for higher-demand applications.

Aluminum oxide's thermal conductivity typically ranges from 18 to 36 W/(m·K), and its coefficient of thermal expansion (CTE) is between 4.5 and 10.9 x 10⁻⁶/K, making it compatible with common semiconductor materials. However, compared to other high-thermal-conductivity ceramic materials, its heat dissipation capabilities are relatively lower, limiting its use in applications requiring extreme thermal performance.

Aluminum Nitride (AlN)

Aluminum nitride offers much higher thermal conductivity than aluminum oxide, typically ranging from 80 to 200 W/(m·K) at room temperature, and can reach up to 300 W/(m·K). Its CTE closely matches silicon, making it an ideal substrate for power semiconductor devices. In high-power-density applications, AlN’s low dielectric constant and superior thermal management capabilities significantly improve the reliability and performance of devices. However, the high manufacturing cost of AlN limits its use in cost-sensitive areas.

Beryllium Oxide (BeO)

Beryllium oxide is an exceptional high-thermal-conductivity ceramic material, with thermal conductivity surpassing most metals, reaching 330 W/(m·K). It is ideal for extreme high-power-density applications. However, due to its toxicity, strict safety measures are required during manufacturing and use, limiting its application range.

Key Differences Between Ceramic PCBs and Traditional PCBs

Material Difference:

Ceramic PCBs: Made from ceramic materials such as aluminum oxide, aluminum nitride, or beryllium oxide, which offer superior thermal conductivity, high-temperature resistance, and electrical insulation.

Traditional PCBs: Made from organic materials like glass fiber-reinforced epoxy (FR-4) or polyimide, with lower thermal conductivity and heat resistance, suitable for general electronic products.

Thermal Management:

Ceramic PCBs: High thermal conductivity, suitable for high-power electronic devices, allowing quick heat dissipation to prevent overheating.

Traditional PCBs: Poor thermal conductivity, often requiring additional heat sinks or thermal materials for heat management, especially in high-power applications.

Mechanical Strength and Durability:

Ceramic PCBs: High strength, hardness, and corrosion resistance, making them suitable for harsh environments, such as high-temperature, high-pressure, and chemically corrosive conditions.

Traditional PCBs: Lower mechanical strength, prone to damage from moisture, chemical corrosion, and temperature fluctuations.

Electrical Insulation:

Ceramic PCBs: Excellent electrical insulation, particularly suitable for high-voltage applications.

Traditional PCBs: Weaker insulation properties, which can degrade as temperature increases.

Applications:

Ceramic PCBs: Primarily used in applications requiring high thermal conductivity, high-temperature resistance, high current density, and high reliability, such as power electronics, RF circuits, LED lighting, and aerospace.

Traditional PCBs: Widely used in consumer electronics, communication devices, automotive electronics, etc., due to their lower cost and broad applicability.

Manufacturing Complexity:

Ceramic PCBs: Complex manufacturing processes, especially the high-temperature bonding of copper foil to ceramic substrates (e.g., DBC or LTCC/HTCC processes), which increases costs.

Traditional PCBs: More mature and simpler manufacturing processes, especially for FR-4 PCBs, with lower costs.

Ceramic PCBs vs. Aluminum PCBs

1. Differences in Thermal Conductivity:

Aluminum is a good conductor of heat, with a thermal conductivity of up to 237 W/(m·K). However, in aluminum PCBs, an insulating layer between the aluminum base and the circuit layer greatly reduces heat dissipation, becoming a bottleneck in the system’s thermal management.

2. Electrical Insulation and Structural Strength:

Aluminum is a conductor, so aluminum PCBs must use an electrical insulating layer between the circuit and the aluminum base to avoid short circuits. This design is not ideal for heat conduction.

Conversely, ceramic materials have excellent electrical insulation, eliminating the need for additional insulation layers. This allows ceramic PCBs to effectively dissipate heat and maintain stable electrical performance in high-voltage and high-temperature applications. For example, both aluminum oxide and aluminum nitride have high breakdown voltages, making them ideal for high-power equipment.

3. Operating Temperature Range:

Ceramic PCBs offer superior heat resistance compared to aluminum PCBs. Most aluminum PCBs operate effectively within a temperature range of -40°C to 150°C, but ceramic PCBs can endure temperatures as high as 350°C, making them suitable for high-temperature environments, such as power devices, engine control systems, and LED lights that generate high heat.

4. Production Cost:

Aluminum PCBs are relatively inexpensive to manufacture due to their simple structure and widespread availability of aluminum as a material. In contrast, ceramic PCBs, especially those made from aluminum nitride and beryllium oxide, have higher production costs due to their more complex manufacturing processes and expensive raw materials. However, in applications that require superior thermal management and electrical insulation, the higher cost of ceramic PCBs is often justified by their performance benefits.

Advantages of Ceramic PCBs

Excellent Heat Dissipation:

The high thermal conductivity of ceramic materials ensures that heat generated by high-power components can be quickly dissipated, preventing overheating and ensuring stable device operation.

High Electrical Insulation:

Ceramic substrates offer excellent electrical insulation, even at high voltages, making them ideal for applications requiring high power and reliability, such as power electronics, RF circuits, and medical devices.

High Mechanical Strength and Durability:

Ceramic PCBs are highly resistant to physical stress, corrosion, and harsh environmental conditions, making them durable and reliable in critical applications like aerospace electronics.

Improved Reliability at High Temperatures:

Ceramic PCBs can operate in extreme temperatures without performance degradation, ensuring reliable operation in high-temperature environments, such as industrial equipment and automotive electronics.

Applications of Ceramic PCBs

Power Electronics:

Ceramic PCBs are widely used in power modules and power control systems, as their excellent heat dissipation and electrical insulation make them ideal for high-power devices such as inverters, motor drives, and power supplies.

RF and Microwave Circuits:

The low dielectric loss of ceramic materials makes them perfect for high-frequency applications, such as RF communication systems, microwave circuits, and radar equipment. Their ability to maintain signal integrity at high frequencies is crucial for performance.

LED Lighting:

Ceramic PCBs are commonly used in LED lighting applications, especially high-power LEDs. Their superior heat dissipation ensures that LEDs operate efficiently and have a long lifespan.

Medical Devices:

Due to their high reliability, electrical insulation, and heat resistance, ceramic PCBs are used in medical devices that require stable performance, such as imaging systems and surgical instruments.

Aerospace Electronics:

Ceramic PCBs are employed in harsh environments, such as aerospace applications, where reliability, durability, and high performance are critical. These applications often require materials that can withstand extreme temperatures and mechanical stress.

Ceramic PCBs have clear advantages over traditional PCBs and aluminum PCBs, particularly in terms of thermal management, electrical insulation, and mechanical strength. They are the preferred choice in high-power, high-frequency, and high-temperature applications, such as power electronics, RF circuits, and LED lighting. Although ceramic PCBs come with higher manufacturing costs, their superior performance in critical applications makes them a valuable investment for industries requiring reliable, long-lasting electronic solutions.

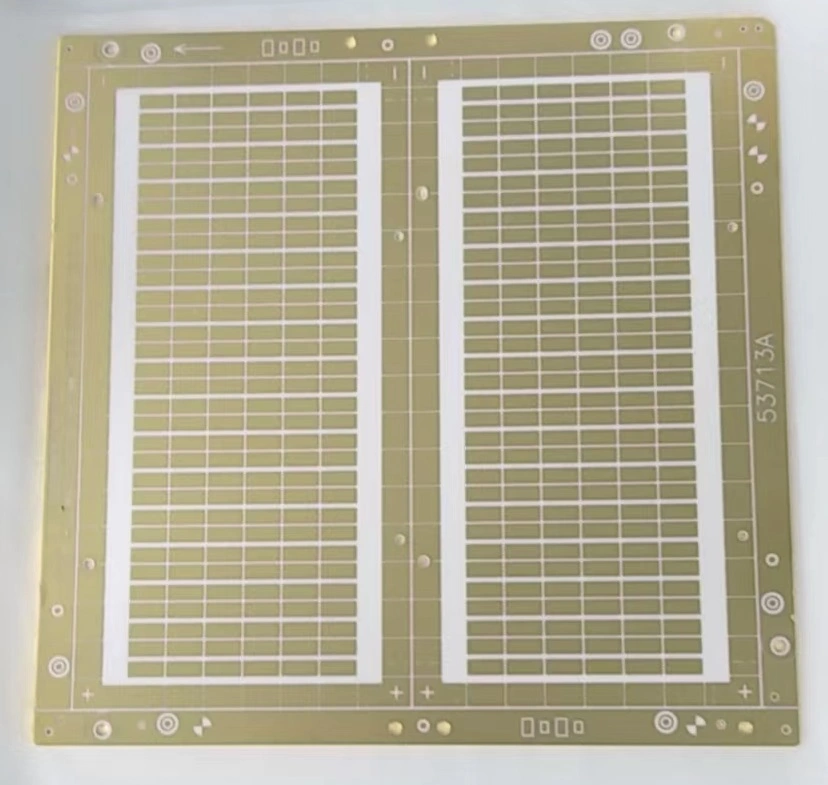

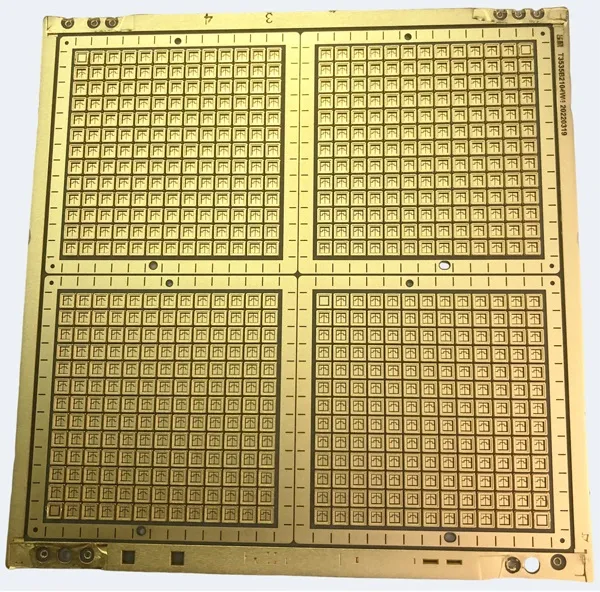

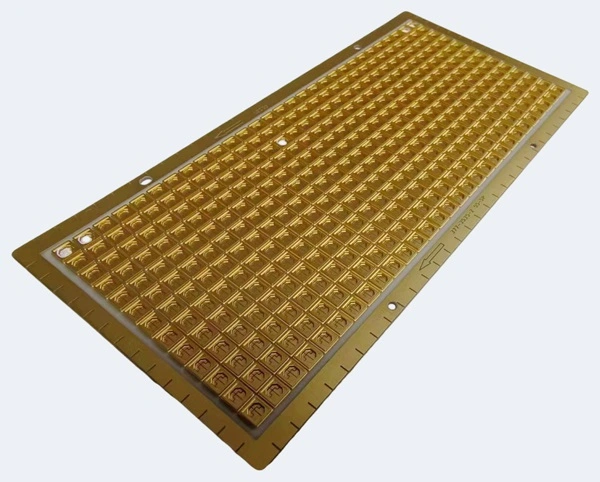

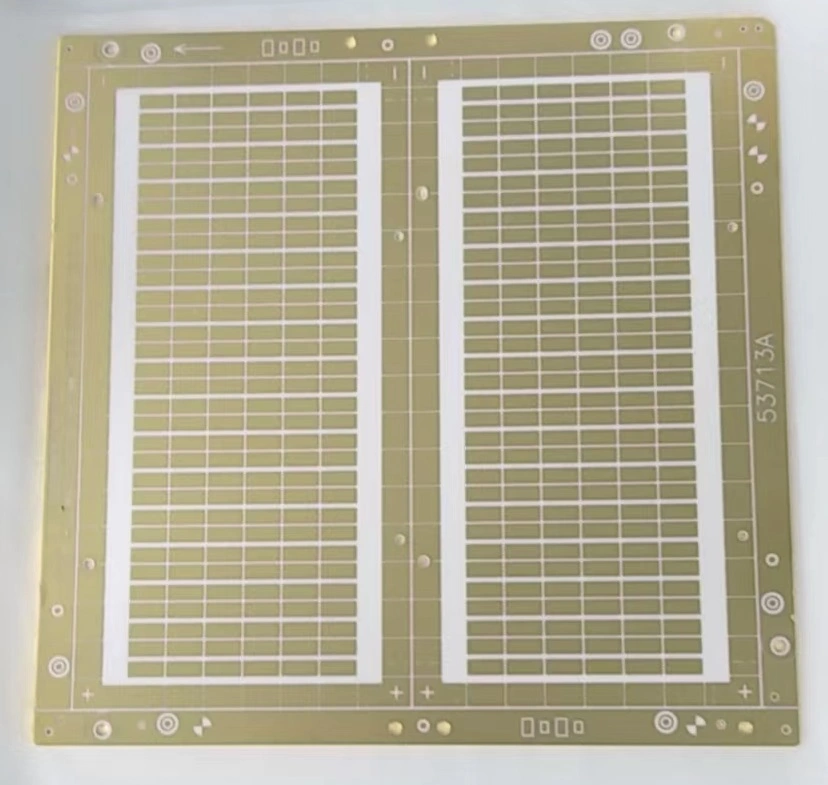

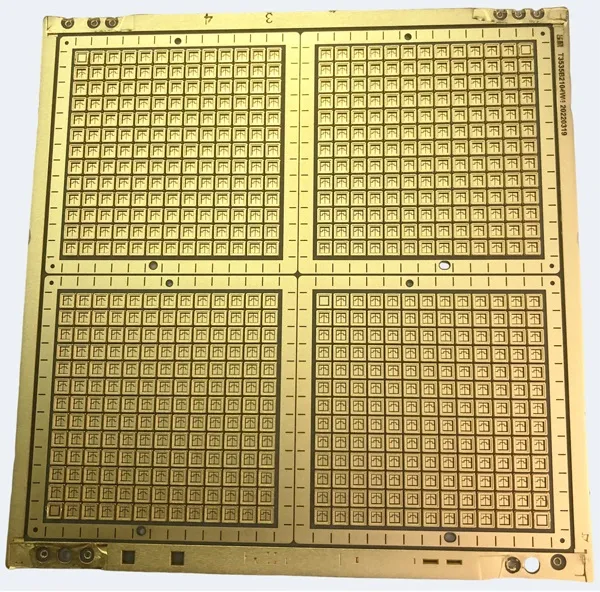

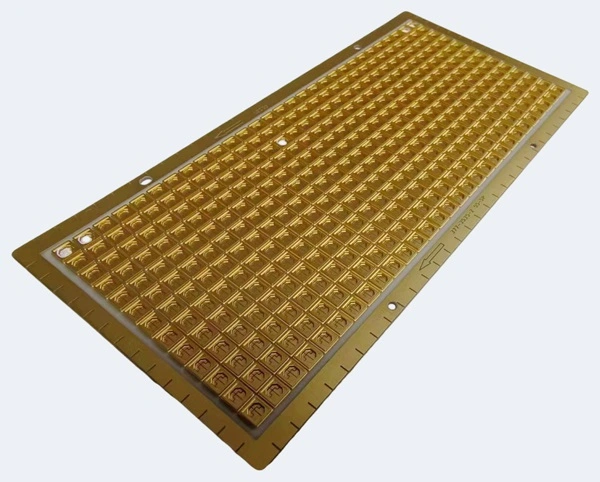

SprintPCB has extensive experience in ceramic

PCB manufacturing and is capable of delivering high-quality products to meet the demands of these challenging applications. Through advanced manufacturing processes and strict quality control, SprintPCB is committed to providing customers with premium ceramic PCB solutions, ensuring product stability and reliability.