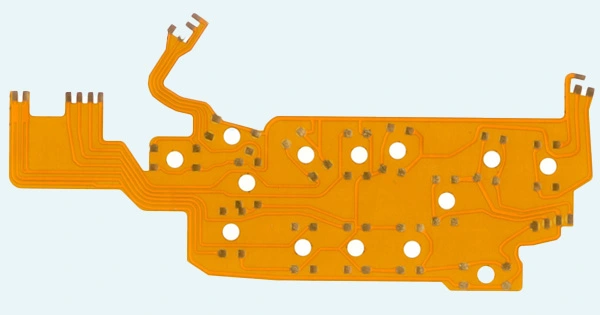

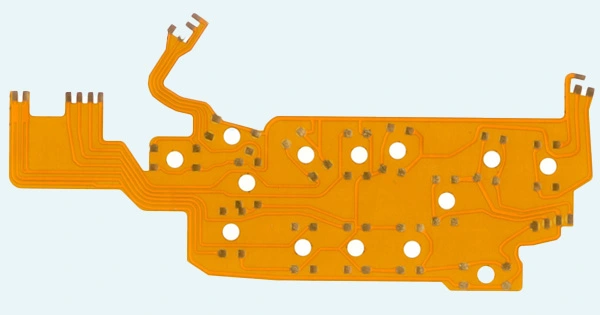

Flexible PCBs have revolutionized the electronics industry with their unique ability to bend, twist, and conform to various shapes without compromising functionality. As a leading

China flexible PCB factory, SprintPCB is committed to delivering high-quality, custom-made flexible PCBs that cater to diverse industry needs. In this article, we will explore the definition, features, and advantages of flexible PCBs, followed by a detailed discussion of their applications across different industries.

Introduction to Flexible PCBs

Flexible PCBs, also known as flex circuits, are electronic circuits designed on flexible substrates like polyimide or polyester films. Unlike traditional rigid PCBs, flexible PCBs can be folded or shaped to fit into compact or irregular spaces, making them ideal for modern electronic devices where space constraints are a critical factor. As a China flexible PCB factory, SprintPCB manufactures flexible PCBs that offer not only versatility in design but also enhanced durability and reliability.

Features and Advantages of Flexible PCBs

Flexible PCBs offer several distinct features that set them apart from rigid PCBs:

- Bendability and Flexibility: The most significant advantage of flexible PCBs is their ability to bend, twist, and flex, which allows for more innovative designs and space-saving solutions in electronic products. This flexibility also contributes to their longevity, as they can withstand repeated bending without breaking.

- Lightweight and Compact: Flexible PCBs are much thinner and lighter than their rigid counterparts. This characteristic is especially important in industries like consumer electronics, where reducing weight and size is crucial.

- High Thermal Management: Flexible PCBs typically have better heat dissipation capabilities due to their thinner substrates and ability to conform to surfaces that promote heat transfer. This makes them suitable for high-temperature environments.

- Durability and Reliability: Manufactured by SprintPCB, a trusted China flexible PCB factory, these PCBs are designed to withstand harsh conditions, including extreme temperatures, vibrations, and exposure to chemicals. Their robustness ensures a longer lifespan and consistent performance.

- Cost-Effective: While the initial design and manufacturing costs might be higher, the reduced need for connectors, cables, and other components often results in lower overall production costs, making flexible PCBs a cost-effective solution in the long run.

Applications Across Various Industries

The versatility and unique properties of flexible PCBs make them invaluable in a wide range of industries. Below are some of the key sectors where flexible PCBs are extensively used:

- Consumer Electronics: In devices such as smartphones, tablets, and wearable gadgets, the demand for smaller, lighter, and more efficient components is ever-growing. Flexible PCBs, with their thin profiles and ability to fit into tight spaces, are ideal for these applications. They are commonly used in connectors, displays, and battery management systems.

- Automotive Industry: The automotive sector relies on flexible PCBs for a variety of applications, including dashboard electronics, lighting systems, sensors, and engine management systems. Their ability to withstand high temperatures and vibrations makes them perfect for use in the demanding environment of automobiles.

- Medical Devices: Flexible PCBs are critical in medical devices due to their biocompatibility, reliability, and compactness. They are used in hearing aids, pacemakers, imaging systems, and other portable medical equipment. Their flexibility allows for more ergonomic and patient-friendly designs.

- Aerospace: The aerospace and industries require components that are lightweight, durable, and reliable under extreme conditions. Flexible PCBs are used in satellites, aircraft systems, and communication devices, where they contribute to weight reduction and enhance performance.

- Industrial Equipment: Flexible PCBs are also used in industrial automation and control systems, where they help in minimizing wiring complexity and improving system reliability. Their ability to manage heat efficiently makes them suitable for high-power applications.

- Telecommunications: In the telecommunications industry, flexible PCBs are used in antennas, signal transmission devices, and network equipment. Their flexibility allows for more efficient designs and improved signal integrity.

As a premier China flexible PCB factory, SprintPCB is dedicated to producing high-quality flexible PCBs that meet the specific requirements of various industries. From consumer electronics to aerospace, the applications of flexible PCBs are vast and varied, making them a cornerstone of modern technology. Whether you need a custom design for a complex application or a cost-effective solution for high-volume production, SprintPCB is your trusted partner in the flexible PCB manufacturing industry.