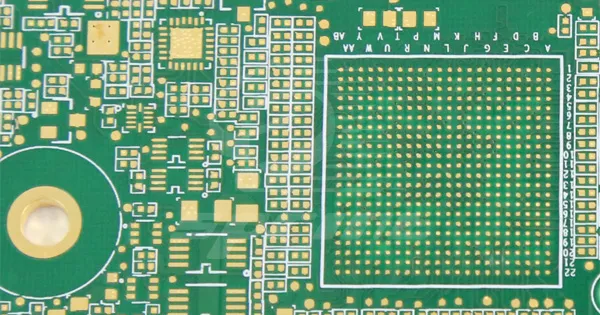

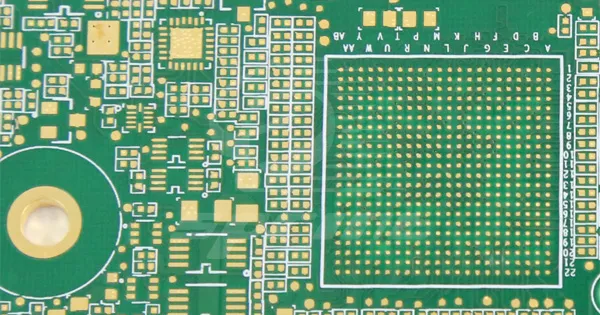

High-Density Interconnect (HDI) printed circuit boards are at the forefront of modern electronic design, offering unparalleled advantages in miniaturization, performance, and reliability. SprintPCB, a renowned

HDI PCB supplier, excels in producing these intricate boards, catering to industries that demand cutting-edge technology and precision.

Introduction to HDI PCBs

HDI PCBs are distinguished by their ability to accommodate a high density of components and interconnections within a compact space. This is achieved through the use of finer traces, microvias, and multiple layers, which allow for more connections and components on a smaller footprint compared to traditional PCBs. As a top-tier HDI PCB supplier, SprintPCB specializes in delivering HDI PCBs that meet the stringent demands of today's electronics, providing both reliability and performance in a compact design.

Key Features and Advantages

HDI PCBs are known for their numerous benefits, making them indispensable in various high-tech applications. Here’s a deeper look at their key features and advantages:

High Density of Components:

HDI PCBs can pack more components into a smaller area due to their finer line widths, smaller vias, and higher connection pad density. This high-density construction is essential for devices where space is limited but performance is critical.

Enhanced Electrical Performance:

The reduced distance between components on HDI boards leads to lower signal loss and electromagnetic interference, which translates to faster signal transmission and improved overall circuit performance. This makes HDI PCBs ideal for high-frequency and high-speed applications.

Layer Reduction:

HDI technology allows for the same functionality with fewer layers compared to traditional PCBs. This reduction in layer count not only minimizes the board’s thickness and weight but also lowers manufacturing costs and complexity, without sacrificing performance.

Improved Thermal Management:

HDI PCBs offer better heat dissipation due to their efficient design, which is crucial in preventing overheating in densely packed electronic devices. This improved thermal management ensures the longevity and reliability of the final product.

Versatile Design Capabilities:

The flexibility in design provided by HDI technology enables the creation of complex and multi-functional boards. These boards can be tailored to specific applications, making them suitable for a wide range of industries, from consumer electronics to aerospace.

SprintPCB, as an HDI PCB supplier, ensures that these advantages are fully realized in every board we produce, thanks to our state-of-the-art manufacturing processes and stringent quality control measures.

Applications of HDI PCBs

HDI PCBs are integral to various industries where space, performance, and reliability are critical. Here’s a closer look at the primary applications of HDI technology:

Consumer Electronics:

The demand for smaller, more powerful devices in consumer electronics drives the widespread adoption of HDI PCBs. Smartphones, tablets, laptops, and wearable devices all rely on HDI technology to achieve their compact form factors without compromising on functionality or performance.

Automotive Industry:

Modern vehicles are equipped with an array of electronic systems, including advanced driver assistance systems (ADAS), infotainment systems, and navigation controls. HDI PCBs are used extensively in these systems, providing the necessary compactness and reliability to function under harsh automotive conditions.

Medical Devices:

In the medical field, precision and reliability are paramount. HDI PCBs are utilized in medical devices such as pacemakers, imaging systems, and portable diagnostic tools, where their small size and high performance are essential for patient safety and effective operation.

Aerospace:

HDI technology is also crucial in aerospace applications, where space constraints and rigorous performance standards are common. HDI PCBs are used in avionics communication devices, and other critical systems, where they offer high reliability and durability in extreme environments.

Industrial Automation:

In industrial automation, HDI PCBs enable the creation of compact, high-performance control systems that are integral to modern manufacturing processes. Their robustness and efficiency make them ideal for use in harsh industrial environments.

SprintPCB stands out as a premier HDI PCB supplier with over 17 years of industry experience. Our manufacturing capabilities are tailored to produce high-quality HDI PCBs that meet the complex requirements of our clients across various industries. We are

ISO 9001:2015 certified and have earned

UL certification, underscoring our commitment to quality and safety. At SprintPCB, we combine advanced technology with competitive pricing, ensuring that our customers receive exceptional value for their investment.