Introduction to Multilayer PCBs

Multilayer PCBs are an essential component in modern electronics. They are comprised of multiple layers of conductive materials, typically copper, separated by insulating layers. Unlike traditional single or double-sided PCBs, multilayer PCBs have more than two layers, offering a compact solution for complex electrical circuits.

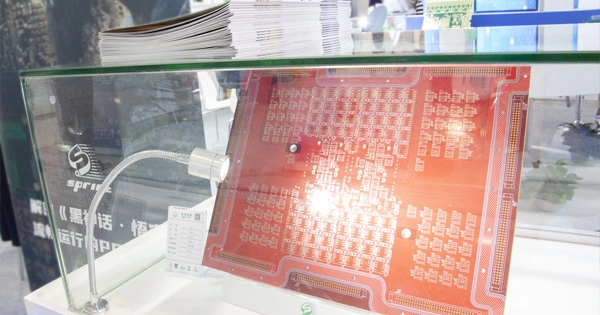

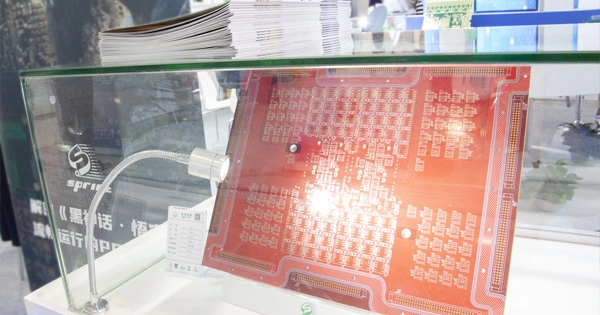

China Multilayer PCB

China Multilayer PCB manufacturing has become a global leader in producing high-quality PCBs due to advanced technological expertise, cost-efficiency, and innovation. At SprintPCB, we are committed to delivering premium China Multilayer PCB solutions for diverse applications, ranging from consumer electronics to aerospace and medical devices.

The Manufacturing Process of Multilayer PCBs

The production of China Multilayer PCBs requires precision and attention to detail to ensure quality, durability, and performance. Here is an overview of the typical manufacturing process at SprintPCB:

Design and Layout:

Our skilled engineers meticulously review and verify design files with advanced software tools. We guarantee that every PCB layout adheres strictly to your specifications, is optimized for both manufacturability and peak performance, and thus minimizes the potential for errors during the production process.

Material Selection:

Multilayer PCBs are made using copper-clad laminates, which are chosen based on the specific requirements such as thermal stability, flexibility, and signal integrity. SprintPCB offers various material options, including FR4, Rogers, and flexible materials, catering to different application needs.

Layering Process:

The core component is built by bonding alternating layers of copper and insulating material. Each layer is etched to form the circuit patterns before being stacked together. The layers are aligned accurately using advanced machinery to prevent electrical failures.

Lamination:

After alignment, the layers are bonded together under high pressure and temperature to create a unified, multilayered structure. This process is crucial for the integrity of the board.

Drilling and Plating:

Once the layers are laminated, holes are drilled to create pathways (vias) for electrical connections between layers. The holes are then electroplated with copper to ensure proper conductivity across all layers.

Solder Mask and Surface Finishing:

A solder mask is applied to protect the copper traces from oxidation and solder bridging. At SprintPCB, we offer various finishes like HASL, ENIG, and immersion silver, ensuring reliability in various operating environments.

Quality Control:

Each multilayer PCB undergoes rigorous testing, including Automated Optical Inspection (AOI) and electrical testing, to ensure there are no defects. We prioritize precision and consistency, delivering reliable PCBs that meet customer specifications.

Advantages of Multilayer PCBs

Multilayer PCBs offer numerous benefits over single and double-sided alternatives:

Compact Design:

Multilayer PCBs are compact, allowing for high-density connections in a small footprint. This is particularly useful in industries where space-saving is critical, such as mobile phones and wearables.

Enhanced Performance:

The additional layers allow for greater complexity in circuit design, improving electrical performance, signal integrity, and reducing cross-talk. The proximity of the layers also enhances electromagnetic interference (EMI) shielding.

Higher Durability:

The lamination process used in multilayer PCBs increases their strength and durability, making them more resistant to environmental stresses like heat and vibration.

Increased Functionality:

With more layers, the functionality of the board is increased, allowing for more sophisticated applications. This makes multilayer PCBs ideal for use in high-tech industries such as aerospace, medical devices, and telecommunications.

Applications of Multilayer PCBs

Multilayer PCBs are used across various industries due to their versatility, compact design, and enhanced functionality. Some of the common applications include:

Consumer Electronics: Smartphones, tablets, and wearables rely heavily on multilayer PCBs due to their space-saving nature and advanced functionality.

Telecommunications: Multilayer PCBs are crucial for creating the infrastructure for high-frequency communications, such as routers, switches, and other network devices.

Medical Devices: In medical applications, reliability and precision are critical. Multilayer PCBs are used in devices such as pacemakers, imaging equipment, and other life-saving technologies.

Automotive: Modern vehicles are equipped with a multitude of electronics, from engine management systems to advanced driver-assistance systems (ADAS), all of which rely on multilayer PCBs.

Aerospace and Defense: Multilayer PCBs are ideal for mission-critical applications in aerospace and defense industries due to their ability to withstand harsh environments and deliver reliable performance.

Why Choose SprintPCB for China Multilayer PCBs?

SprintPCB stands out as a leading China Multilayer PCB manufacturer for several reasons:

Expertise in Multilayer PCB Manufacturing:

With years of experience and a team of skilled professionals, SprintPCB is dedicated to providing high-quality PCB manufacturing. We specialize in complex multilayer designs, ensuring each board meets strict industry standards.

Wide Range of PCB Solutions:

From flexible PCBs to HDI and RF boards, SprintPCB offers a comprehensive range of PCB solutions. We serve diverse industries, including medical, automotive, aerospace, and consumer electronics.

Advanced Manufacturing Technology:

SprintPCB utilizes state-of-the-art machinery to ensure precision in the fabrication process. This allows us to produce highly reliable and durable multilayer PCBs that meet customer specifications.

Affordable and Timely Delivery:

We offer competitive pricing without compromising on quality, and our efficient production processes enable timely delivery of orders, whether for prototyping or mass production.

Custom-Made Solutions:

We cater to unique customer needs, producing custom-made China Multilayer PCBs that are tailored to specific applications, ensuring maximum performance and reliability.

Multilayer PCBs are the backbone of modern electronic devices, offering a compact and efficient solution for complex circuits. As a trusted China Multilayer PCB manufacturer, SprintPCB delivers high-quality, custom-made PCBs for various industries, leveraging cutting-edge technology and a commitment to excellence. By choosing SprintPCB, you are investing in quality, reliability, and superior customer service.

China Multilayer PCB manufacturing has become a global leader in producing high-quality PCBs due to advanced technological expertise, cost-efficiency, and innovation. At SprintPCB, we are committed to delivering premium China Multilayer PCB solutions for diverse applications, ranging from consumer electronics to aerospace and medical devices.

China Multilayer PCB manufacturing has become a global leader in producing high-quality PCBs due to advanced technological expertise, cost-efficiency, and innovation. At SprintPCB, we are committed to delivering premium China Multilayer PCB solutions for diverse applications, ranging from consumer electronics to aerospace and medical devices.