In the realm of electronics, circuit board manufacturing stands as a fundamental process that brings our devices to life. It’s an intricate procedure that transforms a mere concept into a tangible product, powering the technology we use daily.

Circuit board manufacturing begins with a design. Engineers create a blueprint of the circuit, detailing the layout and connections. This design serves as the roadmap for the manufacturing process.

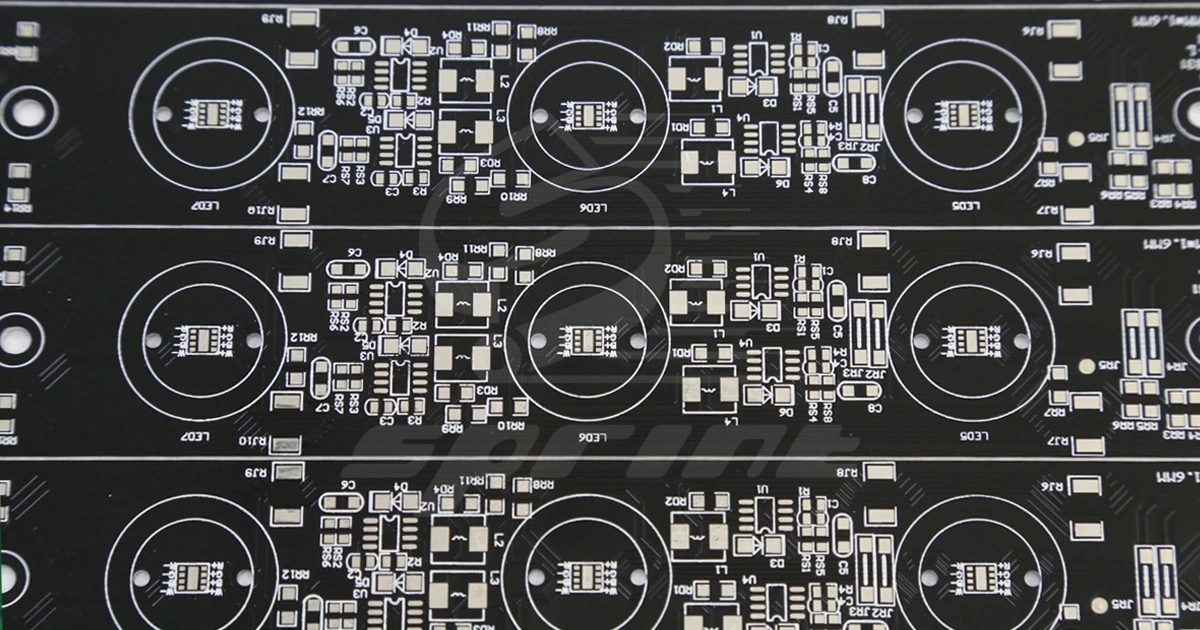

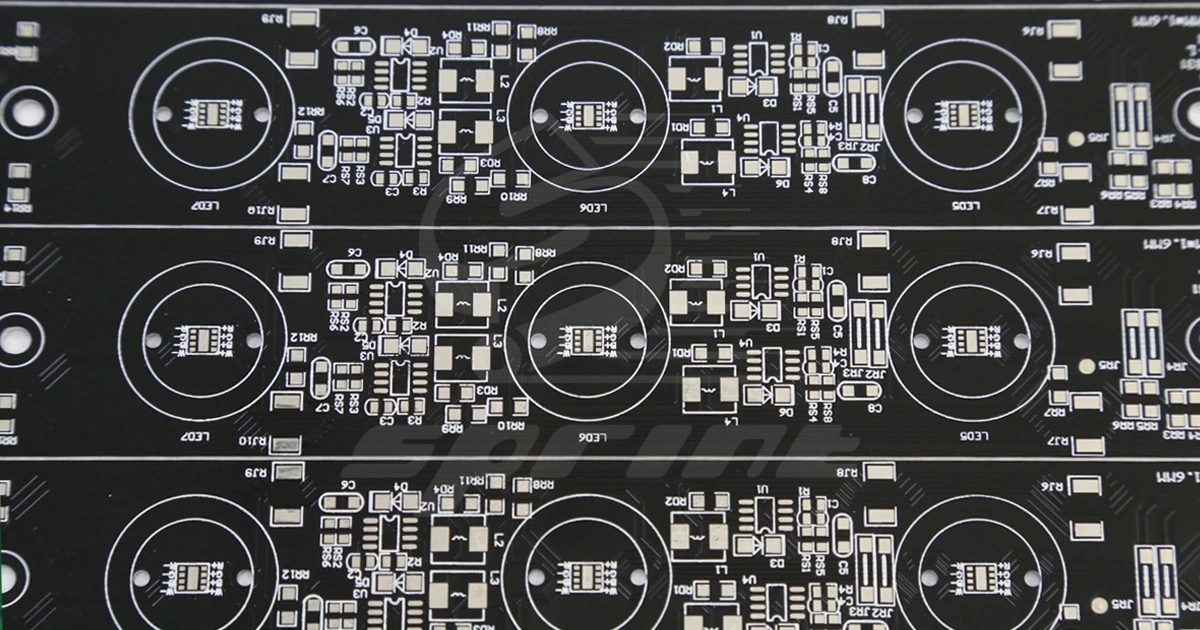

The next step involves transferring this design onto a substrate, typically made of fiberglass or composite epoxy. This substrate forms the body of the circuit board. The design transfer is often achieved through a process called etching, where unwanted copper is removed from the coated substrate, leaving behind the desired circuit pattern.

Once the design is etched onto the board, holes are drilled at designated points. These holes, or vias, allow for electrical connection between different layers of the board. They are then coated with a layer of copper and other metals to ensure good conductivity.

The final stage in circuit board manufacturing is testing. Each board undergoes rigorous checks to ensure functionality and reliability. Any faults detected are rectified before the boards are packed and shipped off for assembly.

Circuit board manufacturing is a testament to human ingenuity and precision. It’s a complex yet fascinating process that underscores our technological advancements. As we continue to innovate and push boundaries, this field will undoubtedly evolve, offering even greater possibilities for our electronic future.