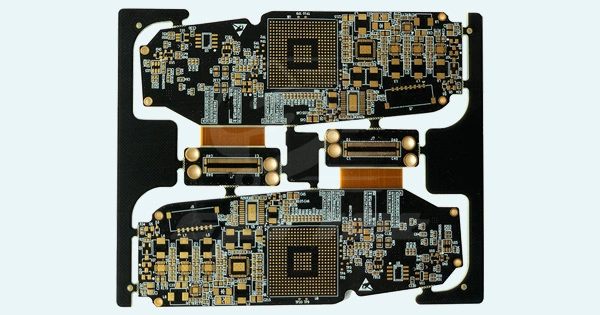

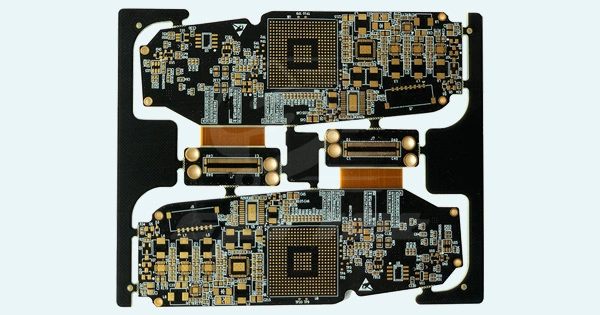

In the realm of modern electronics, Rigid-Flex PCB fabrication has become an essential technology, offering unparalleled versatility and reliability. As a leading manufacturer specializing in

Rigid-Flex PCB fabrication, SprintPCB is committed to delivering top-tier products that meet the stringent demands of today's electronic applications. This article delves into the intricate processes involved in Rigid-Flex PCB fabrication, highlighting the craftsmanship and precision that define our products.

Understanding Rigid-Flex PCB

Rigid-Flex PCBs combine the best attributes of rigid and flexible circuit boards, providing designers with a versatile solution that enhances device performance while reducing space and weight. The fabrication of Rigid-Flex PCBs involves several critical steps, each requiring meticulous attention to detail and advanced technological processes.

Material Selection

The foundation of Rigid-Flex PCB fabrication begins with the selection of high-quality materials. SprintPCB uses industry-leading substrates such as polyimide for the flexible layers and FR4 for the rigid sections. These materials are chosen for their excellent thermal stability, mechanical strength, and flexibility, ensuring that the final product can withstand the rigorous conditions of its intended application.

Layer Stack-Up

One of the unique aspects of Rigid-Flex PCB fabrication is the layer stack-up configuration. This process involves precisely arranging multiple layers of rigid and flexible materials in a specific sequence. The design of the stack-up is critical to the PCB's performance, as it must balance flexibility and rigidity while maintaining electrical integrity. SprintPCB's engineers use sophisticated software to optimize the stack-up, ensuring that each layer is correctly aligned and bonded.

Photolithography and Etching

Once the layer stack-up is defined, the next step in Rigid-Flex PCB fabrication is photolithography. This process involves coating the PCB with a photosensitive material and exposing it to ultraviolet light through a mask that defines the circuit pattern. The exposed areas are then developed, leaving behind a precise pattern that is etched to create the conductive traces. This step requires extreme precision to ensure that the traces are accurately formed and free of defects.

Drilling and Plating

Drilling is another critical step in Rigid-Flex PCB fabrication. Microvias and through-holes are drilled to connect the different layers of the PCB. SprintPCB utilizes advanced laser drilling technology to create precise and clean holes. After drilling, the holes are plated with copper to establish reliable electrical connections between the layers. The plating process involves electrochemical deposition, which ensures uniform coverage and excellent adhesion.

Lamination and Bonding

The lamination process in Rigid-Flex PCB fabrication involves bonding the layers together under high pressure and temperature. This step is crucial for creating a strong and durable structure that can withstand mechanical stresses. The flexible and rigid sections are carefully aligned and bonded to ensure seamless integration. SprintPCB employs state-of-the-art lamination equipment to achieve consistent and high-quality results.

Surface Finish and Assembly

The final steps in Rigid-Flex PCB fabrication include applying a surface finish and assembling the components. Surface finishes such as ENIG (Electroless Nickel Immersion Gold) or HASL (Hot Air Solder Leveling) are applied to protect the copper traces and provide a reliable soldering surface. The PCBs are then assembled with electronic components, using automated pick-and-place machines and reflow soldering processes to ensure precision and reliability.

Quality Assurance

At SprintPCB, quality assurance is paramount in Rigid-Flex PCB fabrication. Each PCB undergoes rigorous testing, including electrical testing, thermal cycling, and mechanical stress testing, to ensure that it meets the highest standards of performance and reliability. Our commitment to quality is reflected in our ISO certification and our dedication to continuous improvement.

Rigid-Flex PCB fabrication is a complex and precise process that requires expertise and advanced technology. SprintPCB is proud to be at the forefront of this field, delivering high-quality Rigid-Flex PCBs that meet the evolving needs of the electronics industry. Our commitment to excellence ensures that our customers receive products that perform reliably in even the most demanding applications.