In today's technology-driven world, electronic devices are everywhere. From the smartphone you hold in your hand to the complex control systems in your car and the appliances in your home, none of them would work without their silent, essential foundation: the Printed Circuit Board, or PCB. As a dedicated manufacturer of high-quality PCBs, the team at SprintPCB wants to demystify this critical component. This guide is designed for engineers, innovators, and procurement managers who need a clear understanding of the modern PCB Board.

Think of a PCB Board as the roadmap and foundation for an electronic device. It's a flat board made of non-conductive material that holds and electrically connects electronic components using a network of conductive tracks, pads, and other features etched from copper sheets. Before the PCB Board, electronics were built using a labor-intensive point-to-point wiring method, which was prone to errors and difficult to mass-produce. The PCB revolutionized electronics by creating a reliable, repeatable, and efficient way to assemble circuits. A basic PCB Board consists of four main parts:

· Substrate: This is the base material that gives the board its rigidity. The most common substrate is a fiberglass material known as FR-4. It's strong, flame-retardant, and provides excellent electrical insulation.

· Copper Layer: A thin layer of copper foil is laminated to one or both sides of the substrate. This is the conductive part of the board. The circuit pathways are etched into this copper, creating the "roads" for electricity to travel.

· Solder Mask: This is the green (or sometimes blue, red, or black) layer you see on top of the copper. Its job is to insulate the copper traces from accidental contact with other metal or conductive bits, preventing short circuits. It also makes soldering components easier.

· Silkscreen: This is the top layer, often white, that contains letters, numbers, and symbols. The silkscreen is used to label components, show test points, and provide other information that helps in assembling and troubleshooting the PCB Board.

A PCB Board serves two primary functions that are crucial for any electronic device. First, it provides mechanical support for all the electronic components. Resistors, capacitors, integrated circuits, and connectors are all physically soldered to the board, holding them securely in place. This creates a sturdy, self-contained unit. Second, and most importantly, it provides the electrical pathways for these components to communicate with each other. The intricate network of copper traces acts like a perfectly organized system of wires, ensuring that power and data signals get exactly where they need to go, reliably and efficiently. This dual role of providing both physical structure and electrical connectivity makes the PCB Board the true backbone of modern electronics.

Not all electronic devices have the same needs, so PCB Boards come in several types to fit different levels of complexity and form factors. At SprintPCB, we specialize in manufacturing a wide range to meet our clients' specific needs.

· Double-Sided PCB Board: As the name suggests, these boards have copper and components on both sides. This allows for more complex and denser circuits by enabling traces to cross over each other on opposite layers. They are the workhorse of the industry, found in countless consumer and industrial electronics.

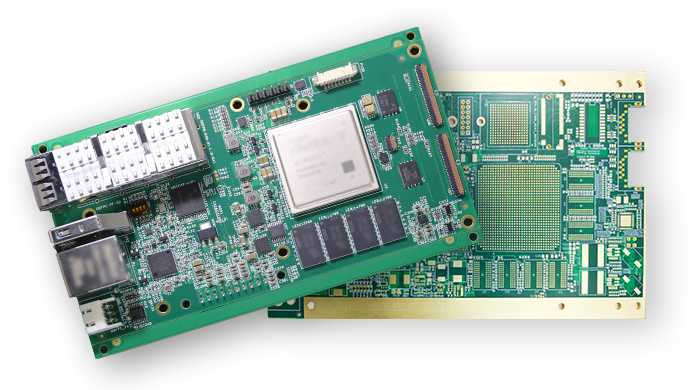

· Multi-Layer PCB Board: For highly complex devices like computers, servers, and smartphones, a multi-layer PCB Board is necessary. These are like a sandwich of double-sided boards, with multiple layers of circuits separated by insulating material. This allows for an extremely high density of components and is essential for high-speed, high-performance electronics.

Beyond these, there are also specialized types like Flexible PCBs, which can bend and fold, and Rigid-Flex PCBs, which combine both rigid sections and flexible sections in a single board.

The performance and reliability of your final product depend entirely on the quality of its PCB Board. A poorly made board can lead to intermittent failures, short circuits, and a host of other problems that can damage your brand's reputation. That's why partnering with an experienced and trustworthy manufacturer like SprintPCB is so important. We understand that a PCB Board is more than just a component; it's the heart of your innovation. We ensure the highest quality by focusing on superior materials, maintaining tight manufacturing tolerances, and implementing rigorous testing at every stage. For every custom PCB Board project, our team at www.sprintpcb.net works with you to ensure your design is optimized for performance and manufacturability, delivering a final product you can trust.

Customer support