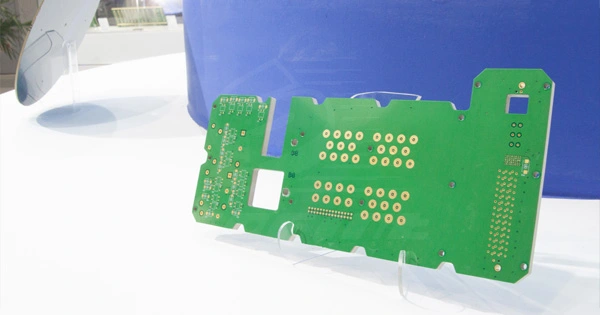

Introduction to Circuit Board Manufacturing

Circuit boards, also known as PCBs, are the foundation of all electronic devices, connecting components and enabling the flow of electricity. These critical components are found in everything from smartphones and computers to medical equipment and industrial machines. For companies that rely on electronic devices, partnering with a reliable

circuit board manufacturing company is essential to ensure performance and product quality.

SprintPCB is a trusted circuit board manufacturing company based in China, specializing in producing high-quality PCBs at competitive prices. With years of experience and cutting-edge manufacturing technologies, SprintPCB provides a wide range of PCB solutions tailored to meet the needs of different industries. In this article, we’ll explore the PCB manufacturing process, discuss the advantages of working with a circuit board manufacturing company, and highlight why SprintPCB is the ideal partner for businesses worldwide.

The Circuit Board Manufacturing Process

Circuit board manufacturing is a complex process that requires precision, quality control, and advanced technology. At SprintPCB, we follow a meticulous process to ensure that every board meets industry standards and customer specifications. Here’s a breakdown of the main steps involved in circuit board manufacturing:

Design and Prototyping:

The process begins with the customer submitting detailed design files, typically in Gerber format. These files contain the schematics and layout of the circuit board, including the placement of components and electrical connections. As a leading circuit board manufacturing company, SprintPCB works closely with clients to ensure that designs are optimized for manufacturability, allowing for efficient production without compromising quality.

Material Selection:

PCBs can be made from various materials, depending on the intended application. The most common material is FR4, a durable and cost-effective fiberglass-reinforced laminate. For specialized applications, such as high-frequency devices or flexible electronics, other materials like polyimide or metal substrates may be used. At SprintPCB, we offer a wide range of materials to meet the specific requirements of different industries.

Patterning and Etching:

After the design is finalized, the copper layers of the circuit board are patterned using a photographic process. A layer of photoresist is applied to the copper, which is then exposed to ultraviolet light through a mask. The exposed areas of the copper are chemically etched away, leaving behind the circuit pathways. As a circuit board manufacturing company, SprintPCB uses state-of-the-art equipment to ensure high precision in this step, minimizing errors and defects.

Lamination:

In multilayer PCB manufacturing, multiple layers of copper and insulating material are laminated together under heat and pressure to form a unified board. This process ensures that all the layers are securely bonded and that the electrical connections between them are properly aligned. SprintPCB specializes in manufacturing multilayer PCBs, catering to industries that require advanced circuit board designs.

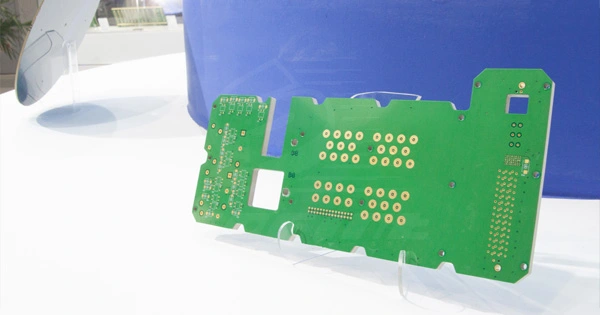

Drilling and Plating:

Once the layers are laminated, holes are drilled for the vias and component leads. These holes are then plated with copper to create electrical connections between the various layers. SprintPCB uses automated drilling machines and precision plating techniques to ensure the accuracy and reliability of these connections.

Solder Mask and Surface Finish:

A solder mask is applied to the board to protect the copper traces from oxidation and to prevent solder bridges during assembly. Afterward, a surface finish is applied to the exposed copper pads. The type of surface finish, whether it’s HASL, ENIG, or immersion silver, depends on the customer’s requirements. As an experienced circuit board manufacturing company, SprintPCB offers various surface finishes to meet different industry standards.

Testing and Quality Control:

Quality control is a critical part of the PCB manufacturing process. Each board is subjected to rigorous testing, including automated optical inspection (AOI), electrical testing, and functional testing, to ensure it meets industry standards and the customer’s specifications. At SprintPCB, we prioritize quality, and our testing processes are designed to deliver defect-free boards to our clients.

Why Work with a Circuit Board Manufacturing Company?

Partnering with a dedicated circuit board manufacturing company like SprintPCB offers several advantages:

Cost-Effective Solutions:

By working with a specialized PCB manufacturer, businesses can benefit from lower production costs due to economies of scale and streamlined manufacturing processes. SprintPCB offers competitive pricing without sacrificing quality, making it an ideal partner for businesses of all sizes.

Advanced Technology:

A professional circuit board manufacturing company has access to the latest equipment and manufacturing techniques, ensuring precision and efficiency. SprintPCB invests in cutting-edge technology to maintain high standards and meet the evolving needs of our clients.

Expertise and Experience:

Manufacturing circuit boards requires extensive knowledge of materials, processes, and industry requirements. SprintPCB’s team of experts has years of experience in PCB production, allowing us to offer solutions that meet both technical and budgetary constraints.

Customization:

Every project is unique, and a dedicated circuit board manufacturing company can provide customized solutions tailored to specific applications. Whether you need single-layer boards or complex multilayer designs, SprintPCB works closely with customers to deliver personalized solutions that meet their exact requirements.

Fast Turnaround Time:

A specialized manufacturer like SprintPCB can handle large-volume production and deliver products within tight deadlines. We understand that time-to-market is crucial for businesses, and we strive to meet customer timelines without compromising on quality.

Applications of Circuit Boards

Circuit boards are essential components in various industries, enabling the functionality of electronic devices. As a leading circuit board manufacturing company, SprintPCB serves a diverse range of markets, including:

Consumer Electronics: Smartphones, laptops, gaming consoles, and other gadgets rely on circuit boards to function efficiently.

Automotive: Modern vehicles incorporate advanced electronics, from engine control units (ECUs) to infotainment systems, all of which depend on high-quality circuit boards.

Medical Devices: PCBs are integral to the operation of life-saving medical devices, such as pacemakers, imaging systems, and diagnostic equipment.

Telecommunications: Circuit boards are used in routers, modems, and communication infrastructure, ensuring reliable connectivity.

Industrial Automation: Circuit boards power machinery and control systems in manufacturing plants, allowing for automated processes and increased productivity.

Why Choose SprintPCB as Your Circuit Board Manufacturing Company?

As a leading circuit board manufacturing company, SprintPCB stands out for several reasons:

- Quality Assurance: Our commitment to quality ensures that every circuit board we produce meets or exceeds industry standards. We use advanced testing methods to guarantee reliable, high-performance products.

- Customization: SprintPCB offers tailored solutions for every customer, whether you need a small batch of prototype boards or large-scale production. We provide flexible options to meet specific project requirements.

- Competitive Pricing: As a circuit board manufacturing company based in China, we offer cost-effective solutions without compromising on quality. Our efficient production methods allow us to provide competitive pricing to clients worldwide.

- Customer Support: From initial consultation to after-sales support, SprintPCB offers comprehensive customer service to ensure a smooth manufacturing process.

Circuit board manufacturing is a crucial aspect of modern electronics, and working with a reliable circuit board manufacturing company is essential for ensuring product quality and performance. SprintPCB offers advanced manufacturing technologies, expert support, and cost-effective solutions tailored to meet the diverse needs of industries worldwide. Whether you need simple or complex circuit boards, SprintPCB is the partner you can trust.