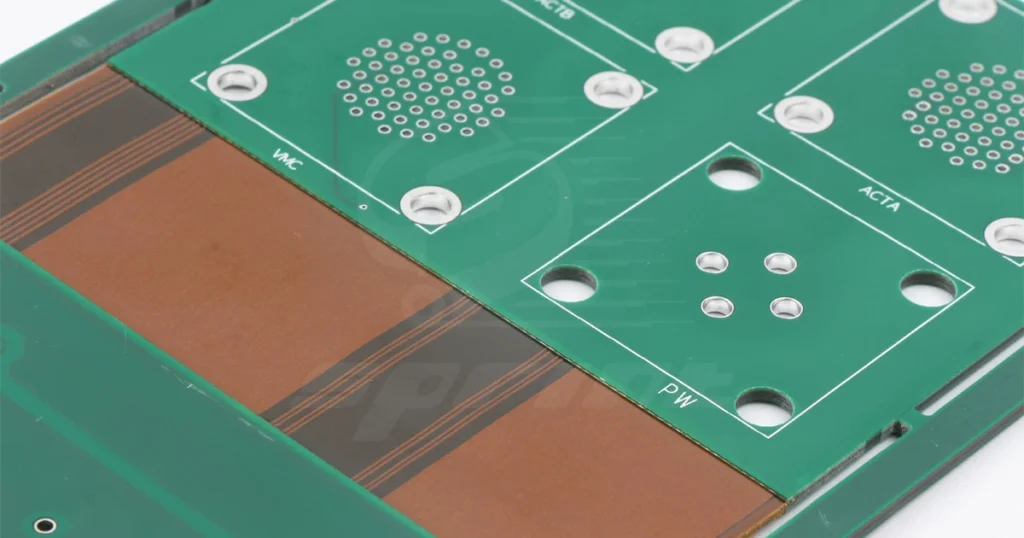

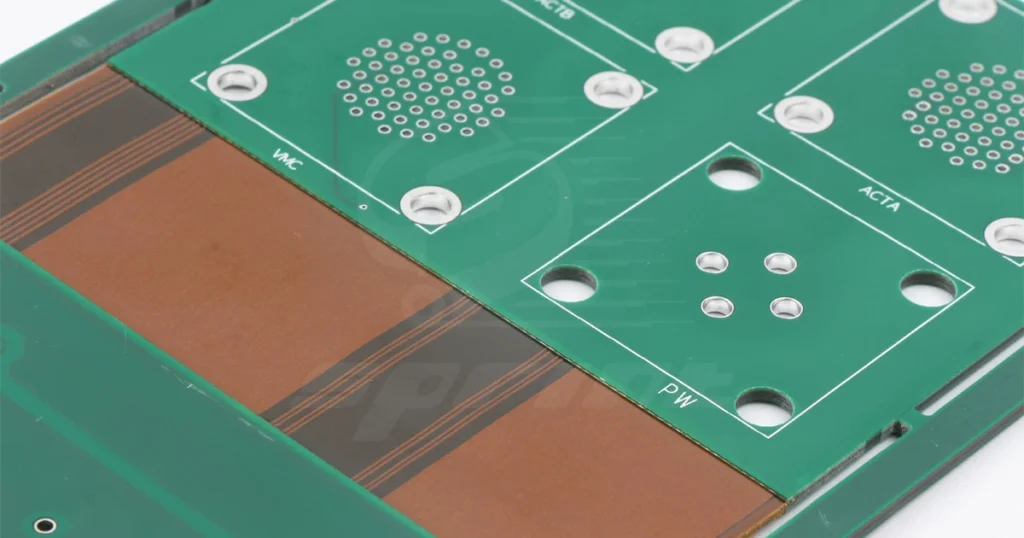

Fast Turn Rigid-Flex PCB provides a reliable solution for electronic projects, offering design flexibility, product durability, and accelerated time to market. In the world of electronic product design and manufacturing, choosing the right printed circuit board (PCB) type is critical to ensuring project success. Fast Turn Rigid-Flex PCB, as an advanced solution that combines rigid and flexible technologies, brings multiple benefits to the project.

The perfect combination of flexibility and durability

Space optimization and design freedom

Fast Turn Rigid-Flex PCB provides unprecedented design flexibility by combining rigid and flexible boards. This combination not only allows the board to be easily laid out in limited or irregular spaces but also allows designers to implement more complex and innovative design solutions.

Improve product durability

Compared with traditional rigid PCB, Rigid-Flex PCB can better resist external pressure and environmental changes due to its unique structure, thereby significantly improving the durability and reliability of the final product.

Accelerate time to market

rapid prototyping

In a highly competitive market, moving products from concept to reality quickly is the key to success.

Fast Turn Rigid-Flex PCB service can provide prototypes in a short time, greatly shortening the cycle from design to production, and helping companies respond quickly to market changes.

Simplify the assembly process

Because Rigid-Flex PCB reduces the need for connectors and redundant wiring, it simplifies the assembly process and further accelerates product development cycles. This all-in-one solution means faster assembly times and lower production costs.

Cost-effectiveness

Long-term reliability reduces maintenance costs

While the initial investment in Fast Turn Rigid-Flex PCBs may be higher than traditional PCBs, the reliability they provide over the entire life of the product can significantly reduce maintenance and replacement costs. This long-term economic benefit makes Rigid-Flex PCB a cost-effective choice.

Reduce material and component requirements

By integrating rigid and flexible areas, Rigid-Flex PCB reduces the need for additional materials and components such as connectors and cables, further reducing overall project costs.

Support complex design requirements

As electronic equipment develops toward smaller size and higher performance, the design requirements for PCBs are becoming higher and higher. Fast Turn Rigid-Flex PCB, with its excellent adaptability and flexibility, can meet the needs of these complex designs, supporting higher-density component layouts and more compact circuit designs.

Fast Turn Rigid-Flex PCB provides an efficient, reliable, and cost-effective solution for a variety of electronic projects. Combining the benefits of rigid and flexible technologies, not only increases design flexibility and product durability but also accelerates time to market while reducing long-term costs. Whether for start-ups pursuing innovation or mature companies that need to iterate products quickly, Fast Turn Rigid-Flex PCB is the ideal choice to achieve project goals.