Printed Circuit Board Assembly refers to the process of soldering or assembling electronic components onto a printed circuit board. This assembly is crucial for the creation of functional electronic devices, as it connects various components, such as resistors, capacitors, and integrated circuits, allowing them to interact and perform their designated functions. PCBA is integral in industries ranging from consumer electronics to automotive, aerospace, and healthcare.

Types of PCBA

Single-Sided PCBA

Single-sided PCBA features components mounted only on one side of the board. This type is generally used in simpler and cost-effective electronic devices due to its straightforward manufacturing process.

Double-Sided PCBA

In double-sided PCBA, components are mounted on both sides of the PCB. This allows for a higher density of components and is suitable for more complex electronic devices.

Multilayer PCBA

Multilayer PCBA involves PCBs with multiple layers of circuitry stacked together. These boards are used in advanced electronics where space is at a premium, and there is a need for high functionality and performance.

Rigid PCBA

Rigid PCBA uses rigid PCBs that are not flexible. These are commonly found in traditional electronic devices like desktop computers and televisions.

Flexible PCBA

Flexible PCBA uses flexible PCBs, allowing them to bend and fold. These are used in applications requiring flexibility, such as wearable electronics and medical devices.

Rigid-Flex PCBA

A combination of rigid and flexible PCBs, rigid-flex PCBA offers the advantages of both types, providing flexibility in design and high durability.

Advantages of PCBA:

- Compact and Efficient Design: PCBA allows for the creation of compact electronic devices with high efficiency, thanks to the dense placement of components.

- High Reliability: Properly manufactured PCBA ensures strong electrical connections and durability, resulting in reliable electronic products.

- Automation Friendly: The PCBA process can be highly automated, leading to consistent quality and reduced manufacturing costs.

- Customizability: PCBA can be customized to fit specific electronic requirements, making it versatile for different applications.

Disadvantages of PCBA:

- Complexity in Repair: Repairing a PCBA can be challenging due to the dense placement of components, especially in multilayer boards.

- Initial Cost: The initial setup cost for PCBA manufacturing can be high, particularly for complex designs and high-volume production.

- Environmental Concerns: The PCBA process involves the use of various chemicals and materials, which can pose environmental challenges if not managed properly.

SprintPCB: Your PCBA Contract Manufacturing Partner

SprintPCB is a leading PCBA factory based in China, specializing in

PCBA contract manufacturing. With over 17 years of experience in the field, SprintPCB has built a reputation for delivering high-quality PCBA solutions that meet global standards. The company offers competitive pricing and ensures that each product is meticulously crafted to fulfill customer specifications.

Why Choose SprintPCB for PCBA Contract Manufacturing?

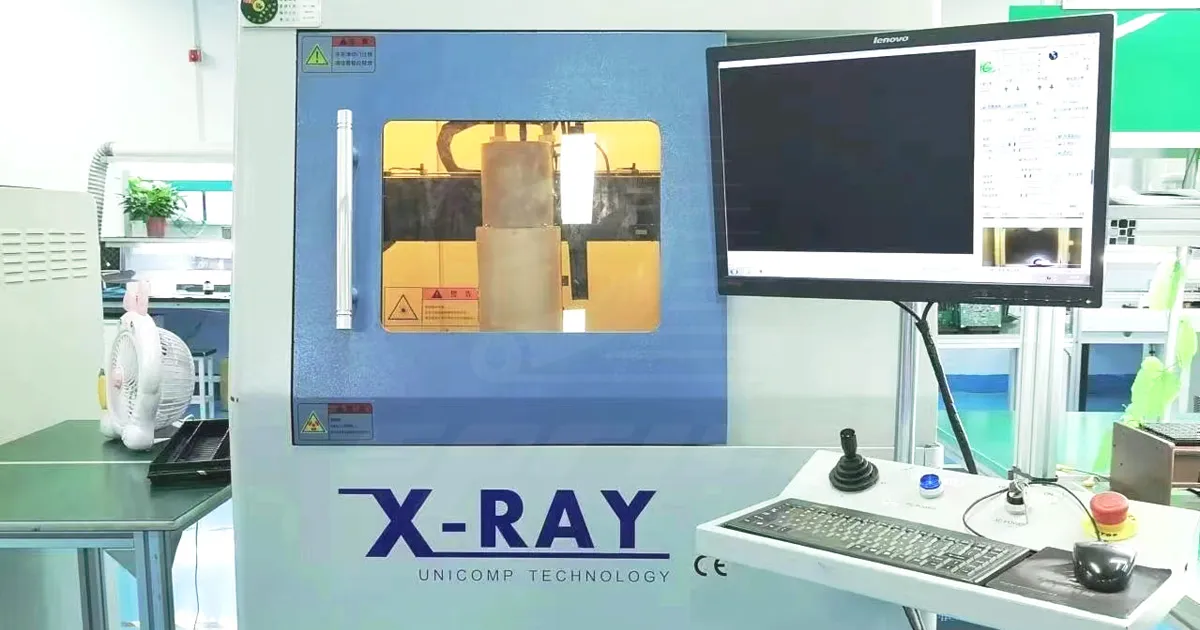

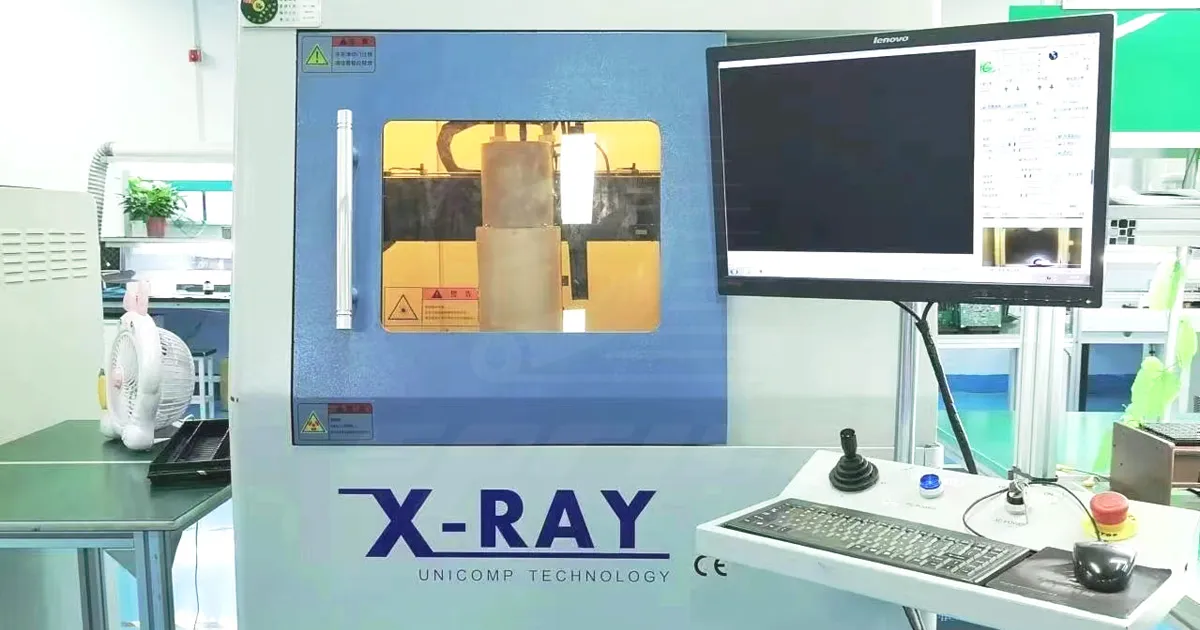

- High-Quality PCBA: SprintPCB is committed to quality, ensuring that every PCBA product undergoes rigorous testing and inspection.

- Competitive Pricing: The company provides cost-effective solutions without compromising on quality, making it an attractive option for businesses worldwide.

- Global Reach: SprintPCB's products are exported to various countries, reflecting their reliability and excellence in PCBA manufacturing.

- Extensive Experience: With over 17 years in the industry, SprintPCB has the expertise to handle diverse PCBA contract manufacturing needs, from simple assemblies to complex multilayer boards.

For businesses looking for a reliable partner in PCBA contract manufacturing, SprintPCB stands out with its commitment to quality, competitive pricing, and extensive industry experience. Whether you need single-sided, double-sided, or multilayer PCBA, SprintPCB has the capability to deliver products that meet your exact requirements. Choose SprintPCB for all your PCBA contract manufacturing needs and experience unparalleled service and support.