In an era where electronics permeate every facet of life—from smart homes to autonomous vehicles—Printed Circuit Board Manufacturing stands as the cornerstone of technological advancement. As a leading force in the PCB industry,

SprintPCB combines decades of expertise with cutting-edge technology to deliver robust, high-performance solutions for industries ranging from aerospace to consumer electronics. This 1800-word guide dives deep into the world of

Printed Circuit Board Manufacturing, exploring its critical processes, emerging trends, quality benchmarks, and how SprintPCB’s commitment to excellence positions it as a global leader.

1. The Evolution of Printed Circuit Board Manufacturing: From Basics to High-Tech

The journey of Printed Circuit Board Manufacturing began with simple single-layer designs in the mid-20th century. Today, it encompasses complex multilayer boards, flexible circuits, and HDI technologies. Modern PCBs are engineered to meet demands for miniaturization, faster data transfer, and extreme durability.

Why PCBs Are Indispensable

- Connectivity: PCBs integrate components into cohesive systems, enabling devices to function seamlessly.

- Scalability: From wearables to industrial machinery, PCBs adapt to diverse size and performance requirements.

- Reliability: Advanced manufacturing techniques reduce failure rates, even in harsh environments.

At SprintPCB, we leverage innovations like

laser direct imaging (LDI) and

automated optical inspection (AOI) to push the boundaries of what PCBs can achieve.

2. Core Stages of Printed Circuit Board Manufacturing: A Step-by-Step Breakdown

Understanding the Printed Circuit Board Manufacturing process is key to appreciating its complexity. Below, we dissect each phase, highlighting SprintPCB’s precision-driven approach.

Stage 1: Design and Engineering

- Schematic Development: Using tools like Altium Designer and Cadence Allegro, engineers map circuitry to meet electrical and thermal specifications.

- DFM (Design for Manufacturing) Analysis: SprintPCB’s team identifies potential production challenges early, optimizing layouts for cost-efficiency and yield.

- Prototyping: Rapid prototypes validate designs before full-scale production, reducing time-to-market.

Stage 2: Material Selection

The choice of substrate and laminates directly impacts performance. Common materials include:

- FR-4: A cost-effective, flame-resistant epoxy laminate for standard applications.

- High-Frequency Laminates(e.g., Rogers 4350B): Ideal for 5G and RF devices.

- Flexible Polyimide: Used in bendable electronics like medical wearables.

SprintPCB offers halogen-free and RoHS-compliant options to align with sustainability goals.

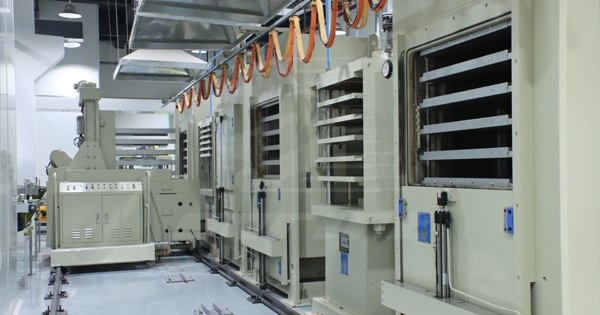

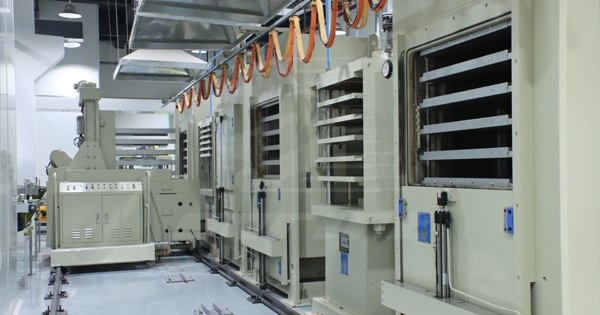

Stage 3: PCB Fabrication

- Imaging: Ultraviolet (UV) or laser exposure transfers circuit patterns onto copper-clad boards.

- Etching: Chemical processes remove excess copper, leaving precise conductive traces.

- Lamination: Multilayer boards are fused under high heat and pressure.

- Plating: Electroless Nickel Immersion Gold (ENIG) or HASL finishes protect against oxidation.

Stage 4: Testing and Quality Assurance

- Electrical Testing: Continuity checks and flying probe tests detect opens/shorts.

- Thermal Stress Testing: Ensures boards withstand temperature fluctuations.

- Cross-Sectional Analysis: Validates layer alignment and via integrity.

SprintPCB’s

100% testing policy and

IPC-A-600 compliance guarantee industry-leading reliability.

3. Advanced Techniques Revolutionizing Printed Circuit Board Manufacturing

To stay competitive, manufacturers must adopt next-gen technologies. Here’s how SprintPCB leads the charge:

HDI Technology

- Microvias: Laser-drilled holes (<150µm) enable ultra-compact designs.

- Stacked Vias: Boost signal integrity in high-speed applications like servers.

Flexible and Rigid-Flex PCBs

- Applications: Medical implants, foldable smartphones, avionics.

- Benefits: Reduced weight, enhanced durability, and 3D configurability.

Additive Manufacturing (3D Printing)

- Rapid Prototyping: Accelerates iteration cycles for complex designs.

- Embedded Components: Resistors and capacitors printed directly onto substrates.

IoT-Optimized PCBs

- Low-Power Designs: Extend battery life for smart sensors.

- RF Shielding: Minimizes interference in connected devices.

4. Quality Standards in Printed Circuit Board Manufacturing

Adherence to global certifications ensures safety and performance. SprintPCB meets:

- IPC Class 2/3: For commercial and high-reliability applications.

- ISO 9001:2015: Rigorous quality management systems.

- UL Certification: Compliance with fire safety and electrical standards.

- RoHS/REACH: Elimination of hazardous substances like lead and cadmium.

5. Industry Applications of Modern Printed Circuit Board Manufacturing

PCBs are ubiquitous. Key sectors include:

- Automotive: Engine control units (ECUs), ADAS systems, EV battery management.

- Healthcare: MRI machines, pacemakers, portable diagnostics.

- Aerospace: Avionics, satellite communication modules.

- Consumer Electronics: Smartphones, AR/VR headsets, IoT devices.

Case Study

SprintPCB partnered with a robotics firm to develop a 20-layer HDI PCB for AI-driven drones, achieving a 30% reduction in signal loss.

6. Sustainability in Printed Circuit Board Manufacturing

As eco-consciousness grows, SprintPCB prioritizes:

- Recyclable Materials: Bio-based laminates and lead-free solders.

- Waste Reduction: Water recycling systems and chemical reuse programs.

- Energy Efficiency: Solar-powered facilities and low-emission processes.

7. Choosing the Right Partner for Printed Circuit Board Manufacturing

Selecting a manufacturer hinges on:

- Technical Expertise: Look for proven experience in your industry.

- Scalability: Ability to handle both prototypes and bulk orders.

- Transparency: Real-time order tracking and detailed reporting.

- Customer Support: DFM guidance and responsive troubleshooting.

Why SprintPCB?

- 48-Hour Quick-Turn Prototyping: Fast-track R&D phases.

- Global Logistics: Doorstep delivery to 100+ countries.

- 24/7 Engineering Support: Expertise on tap for urgent revisions.

8. Future Trends in Printed Circuit Board Manufacturing

- AI-Driven Design: Machine learning algorithms optimize layouts for signal integrity.

- Embedded Passives: Capacitors/resistors integrated into substrates.

- Quantum Computing PCBs: Materials like graphene for ultra-low resistance.