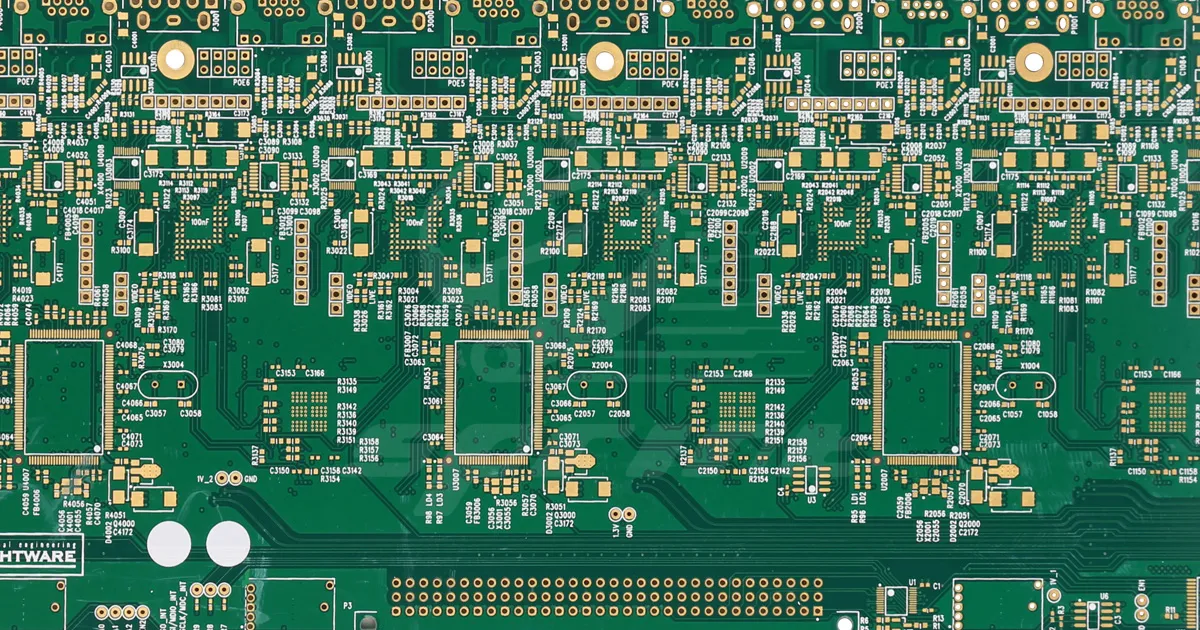

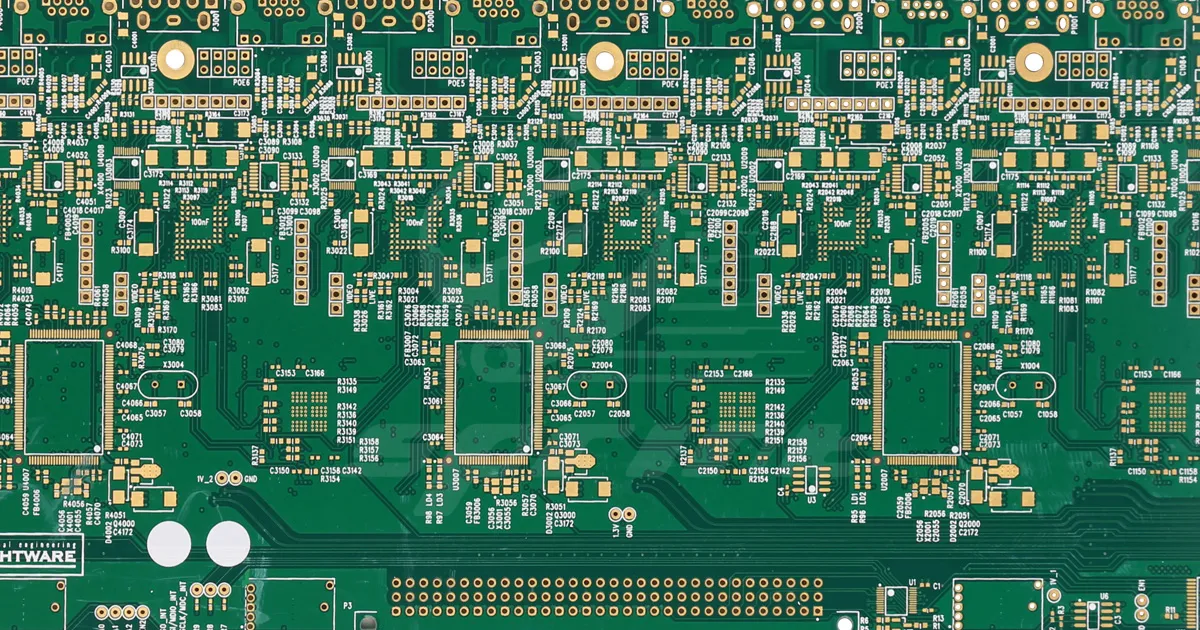

Introduction to Rigid PCBs

Rigid PCBs are a fundamental component in modern electronic devices, providing a stable and durable foundation for electronic circuits. Unlike flexible PCBs, which can bend and fold, rigid PCBs are inflexible and maintain their shape throughout their use. They are commonly found in a wide range of applications, from consumer electronics to industrial machinery, due to their robustness and reliability.

Classification of Rigid PCBs

Rigid PCBs can be classified into several types based on their structure and application:

Description: This type of PCB has only one layer of conductive copper on one side of the board, with the other side used for mounting electronic components.

Applications: Used in simple electronic devices such as calculators, power supplies, and LED lighting.

Double-Sided Rigid PCB:

Description: Features conductive copper layers on both sides of the board, allowing for more complex circuits.

Applications: Commonly used in industrial controls, power converters, and automotive electronics.

Multilayer Rigid PCB:

Description: Comprises three or more layers of conductive copper, with insulating material between each layer. This allows for high-density and complex circuit designs.

Applications: Found in sophisticated electronics like computers, servers, medical devices, and aerospace equipment.

High-Frequency Rigid PCB:

Description: Designed for high-frequency signal transmission, these PCBs use special materials like PTFE (Teflon) to minimize signal loss and interference.

Applications: Essential in communication systems, RF and microwave applications, and high-speed network equipment.

Metal Core Rigid PCB (MCPCB):

Description: Uses a metal core (aluminum or copper) to improve heat dissipation, making it suitable for high-power applications.

Applications: Ideal for LED lighting, power supply systems, and motor drives where heat management is critical.

Description: Combines both rigid and flexible substrates in a single PCB, allowing for complex, three-dimensional circuit designs.

Applications: Used in advanced electronics such as smartphones, wearable devices, and medical equipment where space is limited and flexibility is required.

Advantages and Disadvantages of Rigid PCBs

Advantages of Rigid PCBs:

Durability:

Rigid PCBs are robust and resistant to physical damage, making them ideal for applications that require long-term reliability.

High Density:

Multilayer rigid PCBs can support complex circuit designs with a high number of components and interconnections, suitable for sophisticated electronic devices.

Cost-Effectiveness:

Compared to flexible PCBs, rigid PCBs are generally cheaper to manufacture due to simpler production processes.

Stability and Reliability:

The fixed, non-flexible nature of rigid PCBs ensures consistent performance, which is crucial for applications requiring high reliability.

Disadvantages of Rigid PCBs:

Inflexibility:

Rigid PCBs cannot be bent or folded, limiting their use in applications where flexibility is needed, such as wearable electronics.

Weight:

Typically heavier than flexible PCBs, which can be a disadvantage in portable and lightweight electronic devices.

Size Constraints:

Larger and less adaptable to compact, three-dimensional designs compared to flexible alternatives, which can be a limitation in miniaturized electronics.

SprintPCB: Leading Rigid PCB Manufacturer in China

SprintPCB is a premier China rigid PCB manufacturer, specializing in high-quality rigid PCB production. With over 17 years of experience in rigid flex PCB manufacturing, SprintPCB has established itself as a trusted name in the industry. The company is ISO9001:2015 certified and UL certified, ensuring that their products meet stringent quality standards.

SprintPCB offers a comprehensive range of services, including rigid flex PCB fabrication and fast turn rigid flex PCB solutions. Their expertise extends to producing cheap rigid PCBs without compromising on quality, making them a competitive choice in the market.

The company's product lineup includes rigid flex rigid PCBs, pcb rigid flex boards, and flexi rigid PCBs. As one of the leading rigid PCB manufacturers in China, SprintPCB is committed to delivering high-performance rigid PCB boards at competitive prices. Their state-of-the-art facilities and experienced team enable them to handle both standard and ODM rigid PCB projects, catering to diverse customer needs.

Whether you're looking for a reliable rigid flex PCB manufacturer or a high-quality rigid PCB factory in China, SprintPCB is equipped to meet your requirements. Their dedication to excellence and customer satisfaction makes them a preferred choice for businesses seeking superior rigid PCBs and rigid flex PCBs.

In conclusion, SprintPCB's extensive experience and certifications underscore their capability to provide top-tier rigid PCBs at attractive rigid PCB prices, making them a standout player among rigid PCB manufacturers.