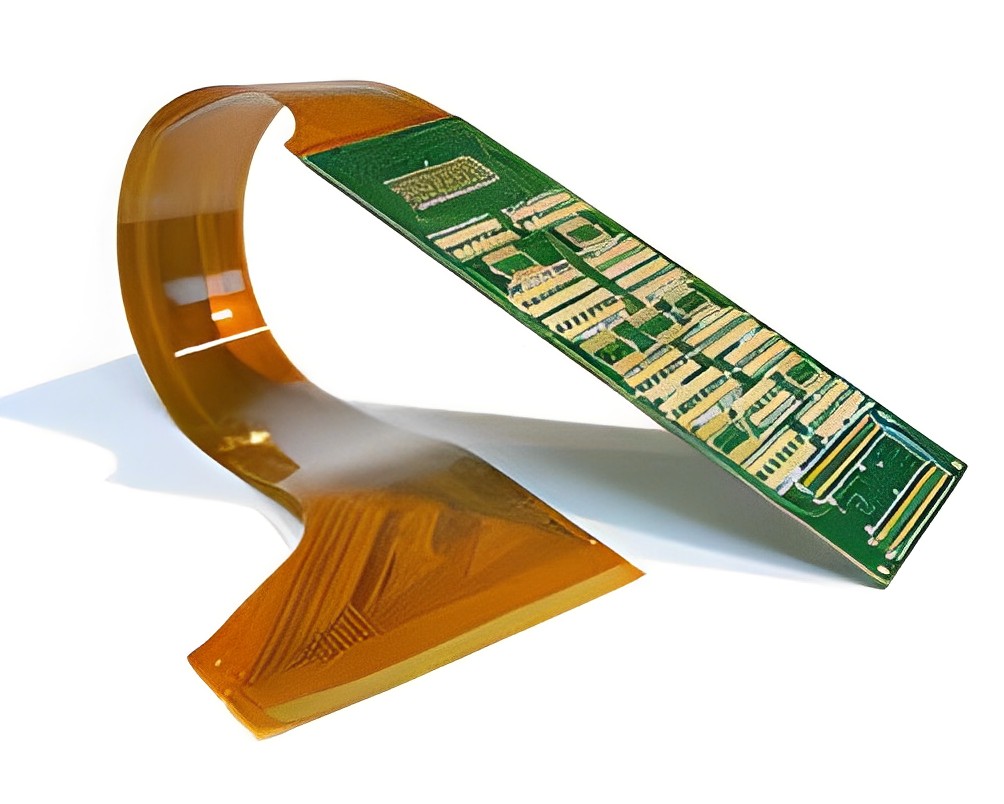

Rigid-flex board is an increasingly common innovative technology in electronic devices. The emergence and development of FPC and PCB have led to the creation of this new product, which combines flexible and rigid boards. Through processes such as lamination, the flexible circuit board and rigid circuit board are combined according to relevant technological requirements, resulting in a combination of the characteristics of rigid boards and flexible circuit boards. This combination provides both strong mechanical stability and reliability, as well as flexibility and adaptability. The advent of rigid-flex boards has changed the design and application of traditional rigid circuit boards, bringing many new opportunities and challenges to the electronics industry. Compared to traditional rigid circuit boards, FPCBs have significant advantages in terms of shape, weight, and space utilization. This provides designers with greater freedom, enabling them to achieve more innovative and precise product designs.

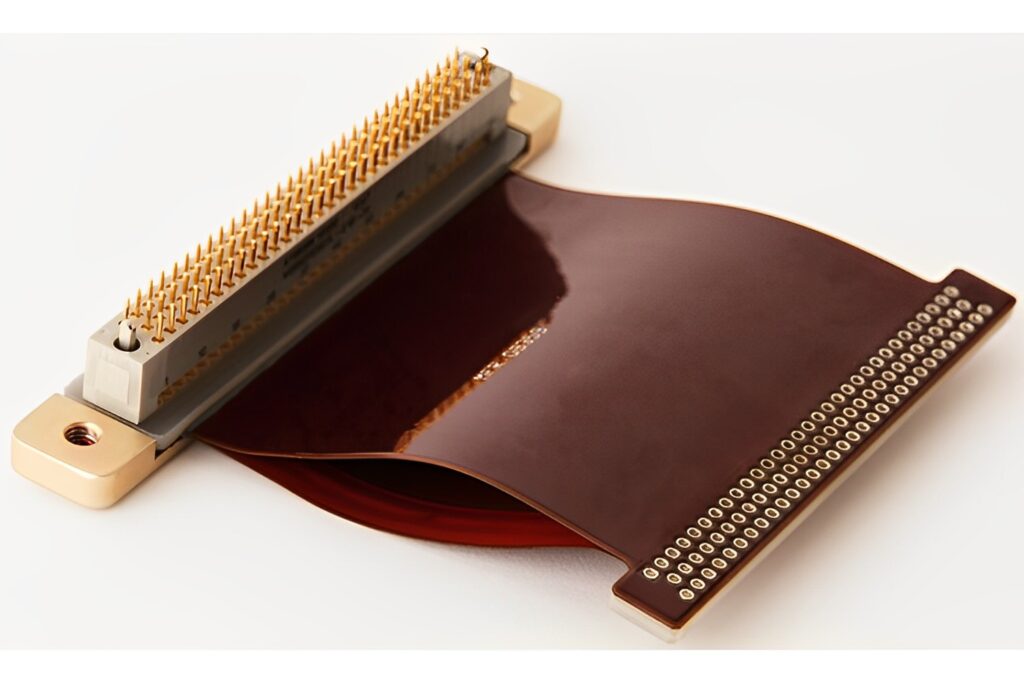

Type 1: Flexible-Rigid Board. A flexible PCB and a rigid PCB are bonded together without plated-through holes (PTH) connections, and the number of layers is more than one.

Type 2: Multi-Layer Flexible-Rigid Board. This type has plated-through holes (PTH) and includes more than two conductor layers.

A coin has two sides, and rigid-flex board is no exception. Let's first discuss the advantages of rigid-flex boards .

Flexibility - With their unique design and manufacturing process, FPCBs demonstrate excellent flexibility and adaptability. These boards can be bent, folded, or flexed to the desired shape to meet various product design requirements. For example, when designing smartphones or wearable devices, FPCBs can be freely bent and molded to accommodate complex shapes. This flexibility provides designers with greater freedom to create more intricate and elegant products. The flexibility of rigid-flex board makes it an ideal choice for wearable device design. For instance, devices like smartwatches, health monitors, and smart glasses need to adapt to various sizes and shapes of wrists, bodies, or faces. The flexibility and bendability of rigid-flex boards allow these devices to snugly fit the user's body contours, providing a comfortable wearing experience.

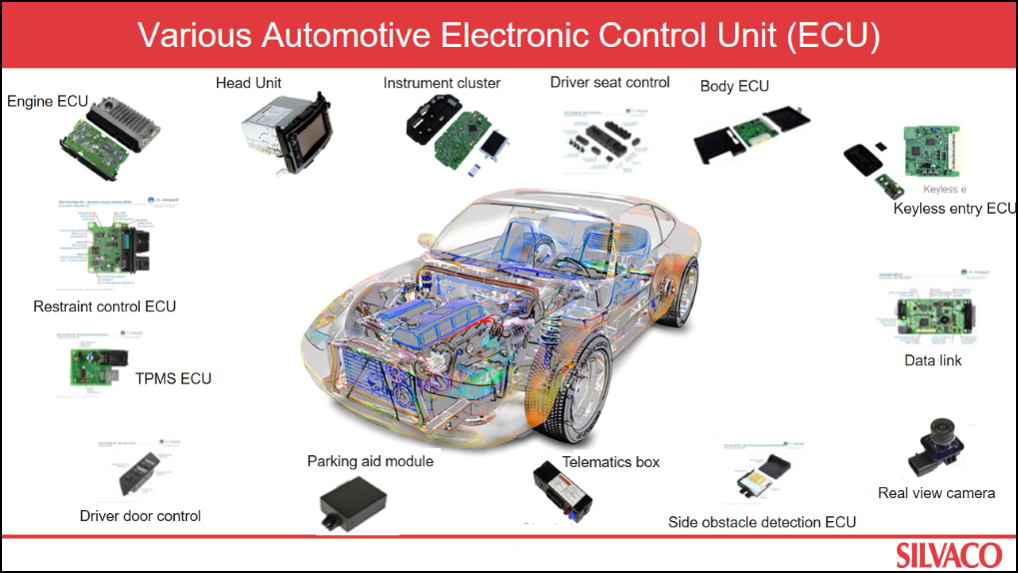

Rigid-flex boards play a crucial role in the design of curved display screens. Modern devices such as smartphones, televisions, and automotive displays are increasingly adopting curved designs to provide a better visual experience. The flexibility of boards allows the display screen to bend along the curve without the need for rigid connectors, enabling seamless curved designs. The adaptability of rigid-flex boards makes it an essential component of foldable devices. For example, products like foldable smartphones and foldable tablets require the circuitry to maintain connectivity when opened and folded. The design of boards allows the circuit board to bend and fold smoothly, enabling seamless transitions between various forms of the device while maintaining reliable circuit connections. The flexibility and adaptability of rigid-flex boards provide innovative solutions for the design of automotive electronic systems. Electronic devices in automobiles need to adapt to narrow spaces and complex shapes while withstanding environmental factors such as automotive vibrations and temperature variations. The flexibility of rigid-flex boards allows circuit boards to be installed compactly within various shaped vehicle components while providing reliable electrical connections.

From wearable devices to curved displays, and even foldable devices and automotive electronic systems, the flexibility and adaptability of rigid-flex boards enable electronic products to accommodate different shapes, sizes, and environmental conditions, providing enhanced user experience and functionality. In addition, rigid-flex boards also offer higher reliability. Compared to traditional rigid boards, rigid-flex boards eliminate connectors or plug-in connections, thereby reducing potential points of failure. This design also reduces issues with inter-circuit connectivity and the risk of electrical noise, providing a more stable and reliable electronic device. In the aerospace field, rigid-flex boards are widely used in equipment such as aircraft and satellites. These devices face harsh operating conditions, including high temperatures, low temperatures, vibrations, and impacts. The high-temperature resistance of rigid-flex boards allows them to operate stably in high-temperature environments while maintaining the reliability of circuit connections. At the same time, their vibration and impact resistance enable them to withstand the intense vibrations and impacts experienced during flight, ensuring the normal operation of electronic equipment. In medical devices such as pacemakers, implanted sensors, and wearable medical devices, the reliability of rigid-flex boards is crucial. These devices need to operate steadily for extended periods, while also requiring durability and resistance to corrosion. The special design and material selection of rigid-flex boards enable them to adapt to changes in the body's environment and withstand the influence of bodily fluids and chemicals. This ensures long-term reliability and stability of medical devices. Industrial control systems often face harsh working environments, including high humidity, corrosive gases, and vibrations, among others. Rigid-flex boards are widely used in these systems to meet their requirements for reliability and durability. The special materials and protective measures of rigid-flex boards enable them to resist moisture intrusion in high humidity environments, while also providing corrosion resistance and oxidation resistance. Furthermore, the vibration resistance of rigid-flex boards ensures the normal operation of the system in vibrating environments, preventing circuit interruptions or malfunctions. Another factor that makes rigid-flex boards popular is their space efficiency. Due to their flexibility and thin design, rigid-flex boards occupy less space in compact electronic devices. This is crucial for modern consumer electronics such as smartphones, tablets, and wearable devices. The use of rigid-flex boards makes the devices thinner and lighter while still meeting complex circuit connectivity requirements. In modern smartphones, space is crucial. The use of rigid-flex boards allows for more compact and lightweight phone designs. These boards can bend and fold according to the shape of the phone, accommodating various tight spaces and closely integrating with other electronic components. Rigid-flex boards can connect different modules within the phone, such as the display screen, camera, battery, and touchpad, resulting in a more compact device structure while providing stable electrical circuit connections. Rigid-flex boards are also widely used in the field of wearable devices. Traditional rigid boards cannot meet the requirements of wearable devices as they need to adapt to the curvature and movement of the human body. Rigid-flex boards can be bent, folded, and rolled to fit the shape of the wrist, arm, or other body parts. This makes wearable devices more comfortable and reduces the space occupied on the body. In the field of automotive electronics, spatial efficiency is one of the key factors. The use of rigid-flex boards allows for more compact automotive electronic modules, thus freeing up more space for other functions and designs. For example, on the car dashboard, rigid-flex boards can connect various instruments and displays in a compact manner, reducing the space requirements for wiring. Additionally, rigid-flex boards can bend and adapt to the curved surfaces inside the vehicle, enabling better space utilization. Medical devices often need to accommodate multiple electronic components and sensors within limited space. The application of rigid-flex boards allows for a more compact design of medical devices, thereby saving space. For example, in implantable medical instruments, rigid-flex boards can bend and flex to conform to the shape of the instrument and establish reliable connections with other components. As a result, medical instruments can better adapt to the patient's internal environment and provide accurate medical monitoring and treatment. Rigid-flex boards are highly favored for their excellent reliability and durability. These boards undergo special treatment and possess characteristics such as vibration resistance, impact resistance, and high-temperature resistance. This makes rigid-flex boards highly suitable for applications that require high reliability and stability, such as aerospace, medical devices, and industrial control systems. Rigid-flex boards are also capable of operating in harsh environmental conditions, such as high humidity, extreme temperatures, and chemical corrosion, without losing performance or causing failures. After discussing the advantages, let's look at the drawbacks of rigid-flex boards.

Customer support