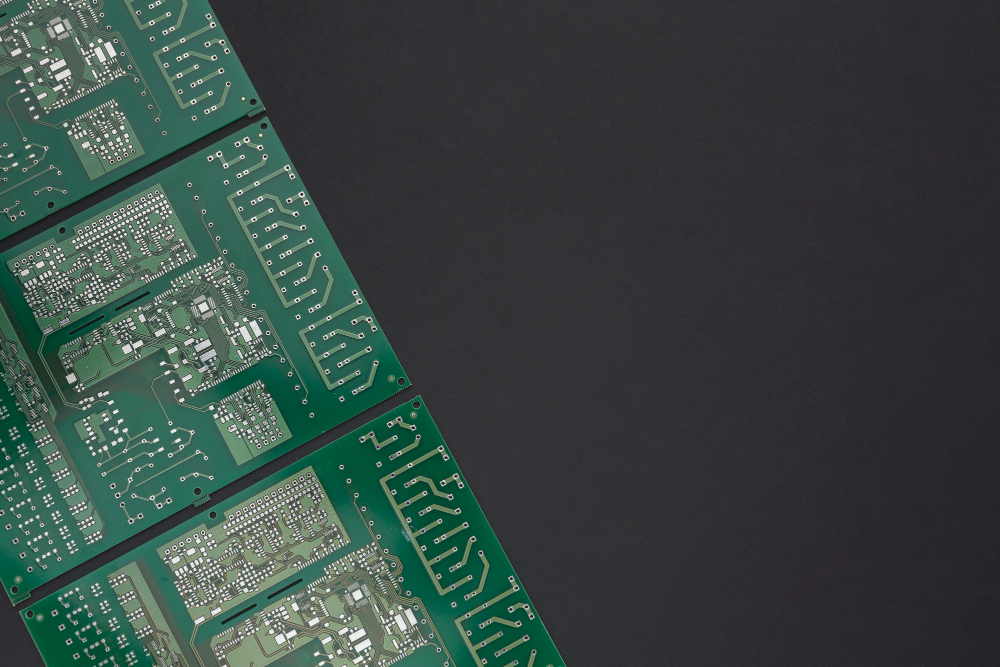

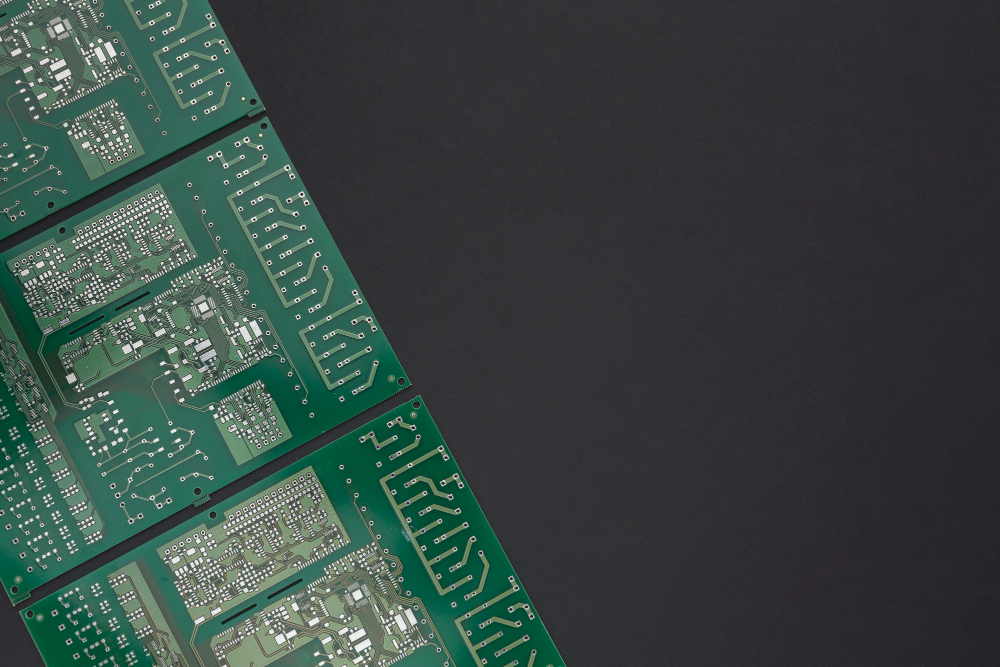

With the rapid development of electronic technology, increased devices and systems require high-quality, high-performance circuit boards. In the electronics industry, Printed Circuit Boards (PCBs), Flexible Printed Circuit Boards (FPCs), and Rigid-Flexible Printed Circuit Boards are the most used types of circuit boards. This article will explore the applications of these circuit boards in different industries.

The different application industries in PCB

PCB (Printed Circuit Board) is a common type of circuit board widely used in various fields.

Telecommunication Industry

Printed Circuit Boards play an important role in communication equipment. Whether it's mobile phones, wireless routers, base stations, or communication network devices, they rely on high-quality Printed Circuit Boards for electrical connections and signal transmission. Printed Circuit Boards in the telecommunications industry need to have stability, high-frequency performance, and anti-interference capabilities to ensure reliable communication.

Computer Industry

Printed Circuit Boards are widely used in the computer hardware field. Key components such as motherboards, graphics cards, and memory modules rely on Printed Circuit Boards to provide electrical connections and signal transmission. Printed Circuit Boards in computer systems not only need to meet the requirements of high-speed data transmission but also ensure stability, anti-interference, and scalability to provide a high-performance computing experience.

Automotive Industry

The electronic systems in modern cars are becoming increasingly complex, requiring high-performance Printed Circuit Boards to support various functionalities. Printed Circuit Boards are widely used in automotive electronics, including engine control units, in-car entertainment systems, navigation systems, and driver assistance systems.

These Printed Circuit Boards need to possess features such as vibration resistance, temperature stability, reliability, and safety to meet the demanding environmental requirements of the automotive industry.

Industrial Control Industry

Printed Circuit Boards are extensively used in industrial control equipment. They are employed for monitoring and controlling industrial processes, such as automated production lines, robot control systems, sensor, and actuator interfaces, and more. In industrial environments, Printed Circuit Boards need to exhibit high stability, durability, resistance to interference, and tolerance to high temperatures to ensure accurate and reliable control and operation.

Medical Industry

Medical devices have strict requirements for high-quality circuit boards. Printed Circuit Boards play a critical role in medical equipment such as cardiac monitors, patient monitors, medical imaging devices, and others. These Boards need to meet stringent electrical safety standards, stability, and reliability requirements. Additionally, they must consider features such as protective performance, interference resistance, and ease of cleaning and disinfection.

Energy Industry

The demand for high-performance circuit boards in the energy sector is constantly increasing. Printed Circuit Boards are widely used in solar energy, wind energy, and power equipment for critical functions such as energy conversion, power control, and monitoring. These Boards need to have high voltage and high current carrying capacity, low energy loss, and high efficiency to meet the requirements of the energy industry.

Printed Circuit Boards, as an important type of circuit board, play a critical role in industries such as telecommunications, computers, automotive, industrial control, medical, and energy. Different industries have different requirements for Printed Circuit Boards, demanding characteristics such as stability, high performance, anti-interference capabilities, safety, and reliability. With the advancement of technology, the application scope of Printed Circuit Boards will continue to expand to meet the ever-changing demands.

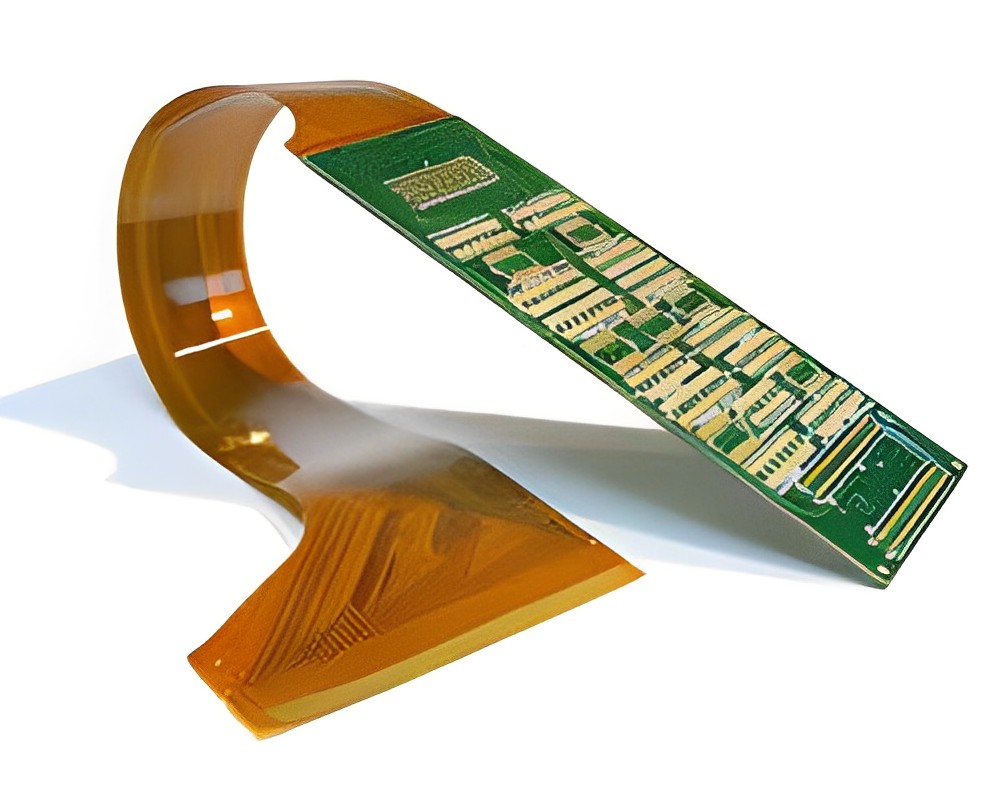

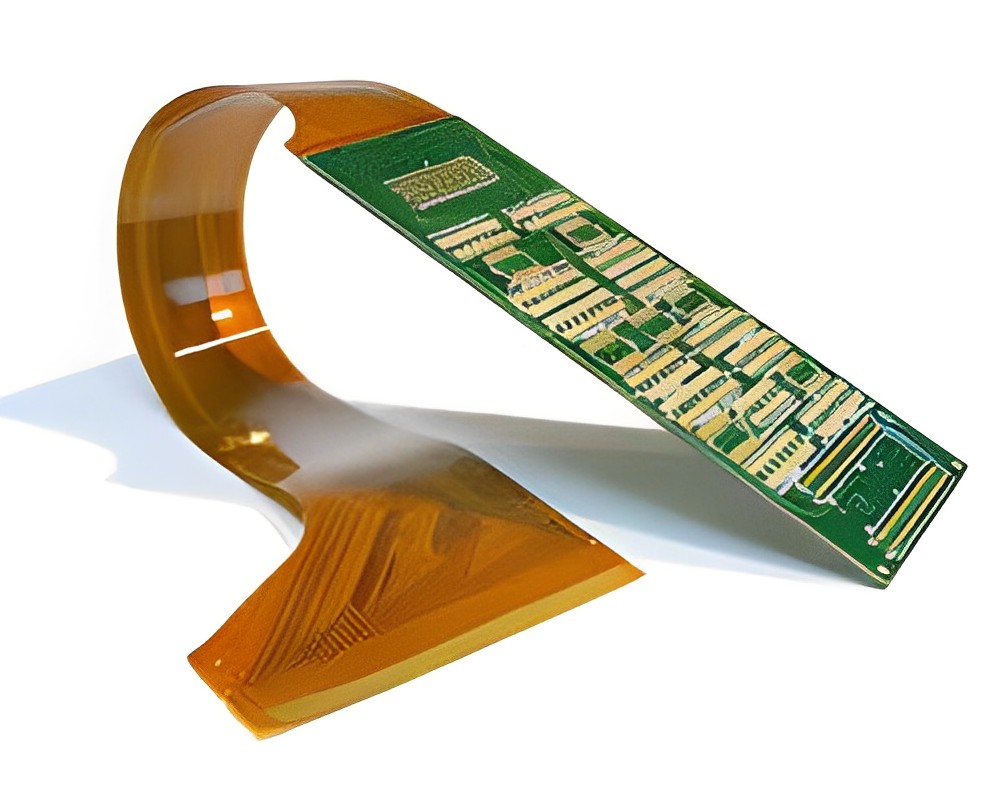

The different application industries in FPC

Mobile Device Industry

Flexible Printed Circuit Board is widely used in the mobile device industry. Devices such as smartphones, tablets, and wearable devices require circuit boards with high flexibility and bending capabilities. Flexible Printed Circuit Board can adapt to the curved designs and small size requirements of devices while providing stable electrical connections. They are used to connect the mainboard to the display screen, camera modules, touchscreens, and various other sensors.

Automotive Industry

In modern cars, the application of electronic systems is becoming increasingly widespread, and Flexible Printed Circuit Board plays an important role in them. There are many circuit board connections within cars that need to bend and adapt to different spatial constraints. Flexible Printed Circuit Board can provide reliable electrical connections for automotive electronic systems, dashboards, door controls, seat controls, and more.

Medical Industry

Flexible Printed Circuit Board has significant applications in medical devices. Its flexibility and bendability allow Flexible Printed Circuit Board to accommodate applications that come into contact with the human body. For example, medical devices like cardiac monitors, patient monitors, and implantable devices often require small-sized and flexible circuit boards to meet the specific needs of the medical industry.

Sumer Electronics Industry

The design of consumer electronic products pursues smaller, thinner, and more flexible designs. Flexible Printed Circuit Board plays a crucial role in meeting these requirements. For example, Flexible Printed Circuit Board is widely used as internal circuit board connectors in consumer electronic products like camera modules, flat-screen TVs, audio devices, and more. Its flexibility and bending capabilities allow circuit boards to adapt to different shapes and sizes of product designs.

For example:

Smartphones are one of the most common products in the mobile device industry. Flexible Printed Circuit Board plays a critical role inside smartphones. They are used to connect the mainboard to the display screen, camera modules, touchscreens, and buttons. Due to its high flexibility and bending capabilities, Flexible Printed Circuit Board can adapt to the curved designs and small size requirements of smartphones while providing reliable electrical connections.

Tablets also require flexible circuit boards to meet their slim design requirements. Flexible Printed Circuit Board connects the mainboard to components such as the display screen, touchscreen, and camera modules inside tablets. Its flexible characteristics enable tablets to be thinner and more portable.

Wearable devices such as smartwatches, smart glasses, and smart headphones also extensively use Flexible Printed Circuit Board. These devices often require flexible circuit boards to adapt to the curves of the user's body while providing electrical connections and signal transmission. Flexible Printed Circuit Board plays a crucial role in connecting different components in wearable devices, such as batteries, sensors, and display screens.

Camera modules play an important role in mobile devices. FPC is used to connect the circuit board of camera modules to the mainboard for image and signal transmission. Due to the flexible nature of FPC, it can adapt to the small size and slim design requirements of camera modules.

The different application industries in rigid-flex PCB

Rigid-Flexible Printed Circuit Board (PCB) is a special type of circuit board that combines rigid and flexible parts together. It harnesses the advantages of both rigid and flexible boards and can play a unique role in specific application scenarios.

Aerospace Industries

Rigid-Flexible boards play an important role in the aerospace sectors. Due to their flexible and reliable structure, they are widely used in missile systems, aircraft electronic control systems, spacecraft communication equipment, and more. These applications have strict requirements for high reliability, high temperature resistance, vibration resistance, and shock resistance in circuit boards, and rigid-flex boards can meet these demands.

Consumer Electronics Industry

With continuous innovation and development in consumer electronics, rigid-flex boards have also found wide application in this industry. Certain consumer electronic products require bendability and foldability while maintaining stability and reliability of the circuit board. For example, foldable smartphones, portable gaming devices, and other products utilize rigid-flex PCBs to meet design requirements. This structure allows the circuit board to adapt to unique product forms and usage patterns.

Medical Industry

Rigid-flex boards also play a crucial role in the medical device field. Medical devices often require miniaturization, flexibility, and wearable capabilities, while demanding high reliability and long-term stability.

Rigid-flex boards can meet these requirements and are applied in implantable medical devices, prosthetic control systems, pacemakers, and more. They can adapt to specific medical needs, come into contact with human tissues, and provide stable electrical connections.

Industrial Control Industry

Rigid-flex boards are widely used in the industrial control field as well. Industrial control equipment necessitates stable signal transmission, high temperature resistance, corrosion resistance, and the ability to adapt to different spatial constraints. The design and structure of rigid-flex PCBs make them an ideal choice for industrial control devices, applied in automated production lines, robot control systems, sensor devices, and more.

PCBs, FPCs, and rigid-flex boards play significant roles in various industries. PCBs are widely used in industries such as communication, computing, automotive, and industrial control. FPCs have unique advantages in industries like mobile devices, automotive, medical, and consumer electronics. Rigid-flex boards play an important role, aerospace, consumer electronics, and medical industries.

With the continuous advancement of technology, the application scope of these circuit board types will continue to expand to meet evolving demands.