PCB (Printed Circuit Board) is an indispensable core component in modern electronic devices, with significance and extensive application areas. PCBs play a significant role in electrical connectivity, mechanical support, signal transmission and space optimization. And PCB applications in a wide range of fields, such as communication equipment, computer and data storage equipment, medical equipment, Consumer appliances, Industrial control and automation, automotive electronics and so on. Effective management of PCB production costs is crucial for electronic device manufacturers and designers. In this article, we will explore the key factors that impact the cost of PCB production and why manage PCB production costs.

What key factors that influence the cost of PCB production?

The cost of PCB production is influenced by various factors, ranging from design complexity and material selection to manufacturing processes, production quantity, supply chain management, and technological innovations. By understanding and effectively managing these factors, manufacturers and designers can optimize PCB production costs while maintaining quality and competitiveness in the ever-evolving electronics industry.

Design and Layout

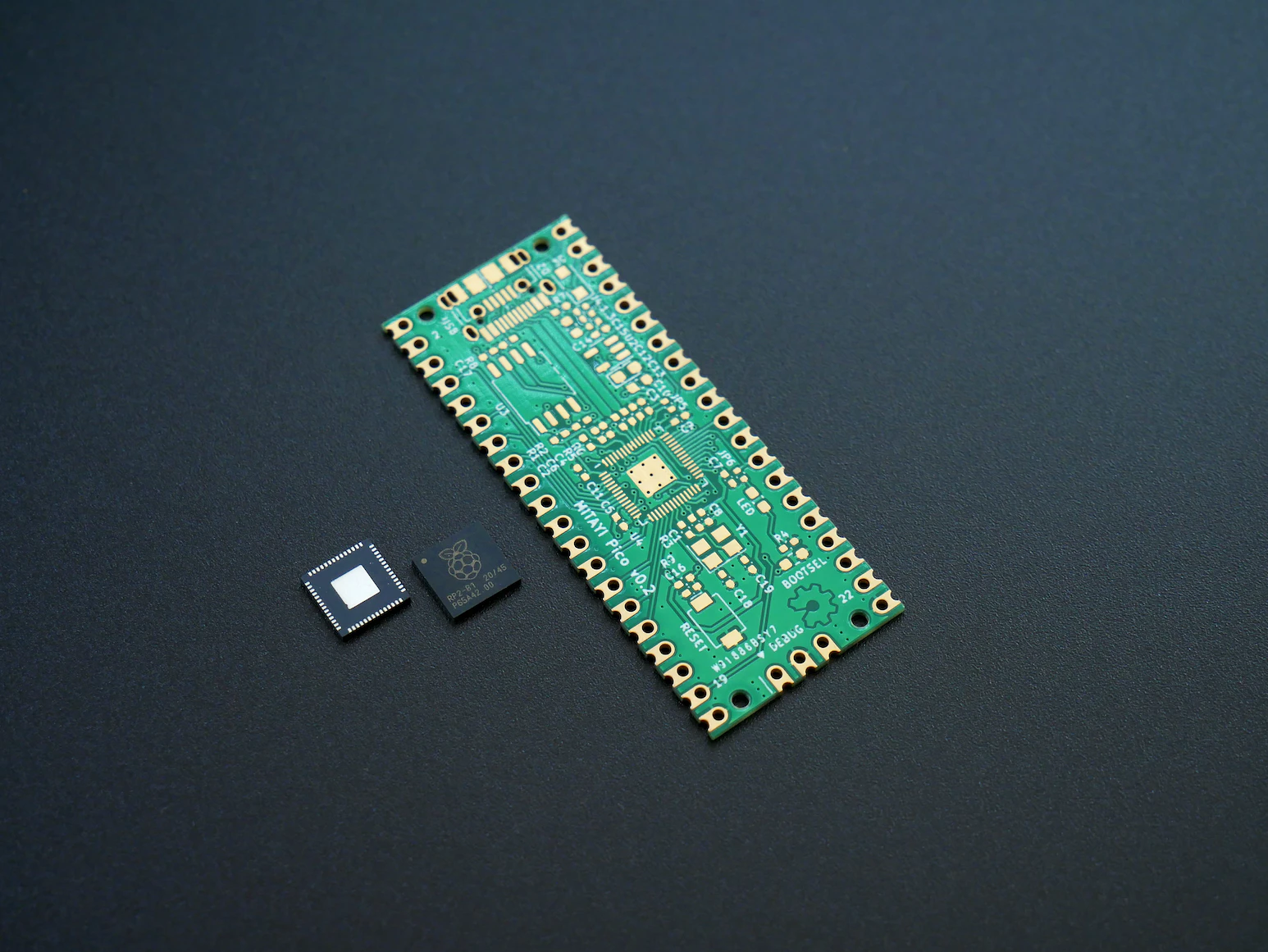

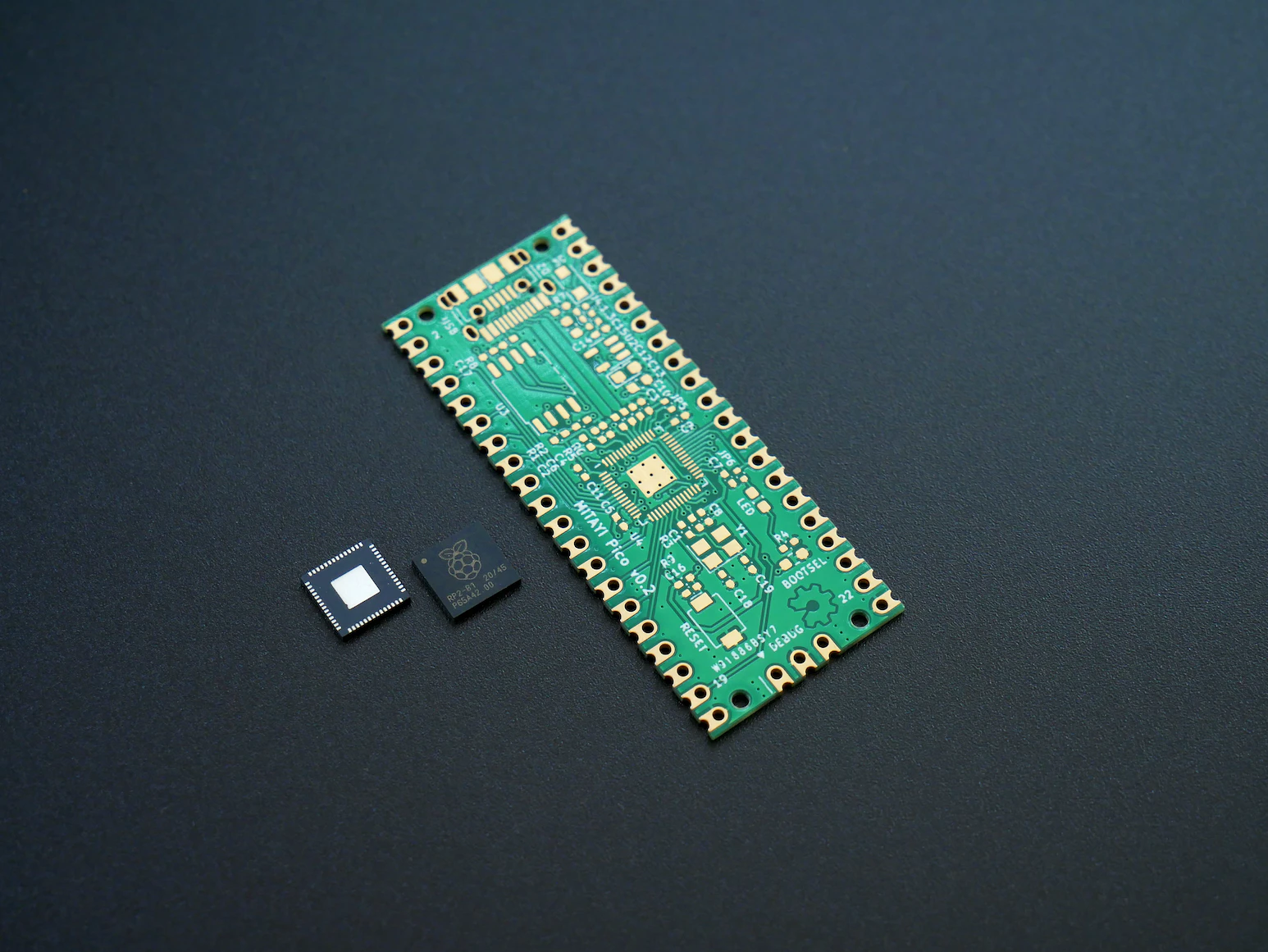

The complexity and layer count of the PCB design can significantly affect production costs. Complex designs with multiple layers require advanced fabrication techniques, specialized materials, and intricate manufacturing processes, resulting in higher costs. Component density, spacing, and the size of the PCB also contribute to the overall production expenses.

Material Selection

The choice of materials for the PCB has a direct impact on the cost of PCB production. Factors such as the type and quality of substrate materials, copper foil thickness, and the need for heat-resistant or chemically resistant materials influence the overall cost. Specialized materials required for high-frequency signal transmission or specific environmental conditions can further increase production expenses.

Manufacturing Processes

The manufacturing processes employed during PCB production greatly affect the overall cost of PCB production. Advanced assembly and soldering techniques, such as surface mount technology (SMT) or through-hole technology (THT), may involve higher equipment costs and skilled labor. Additional processes like solder mask application, tin plating, and printing techniques contribute to the overall cost of PCB production expenses.

Quantity and Scale

The production quantity of PCBs directly impacts the cost per unit. Large-scale production and batch manufacturing often benefit from economies of scale, reducing the overall cost per PCB. Smaller production runs or prototyping, on the other hand, tend to be costlier due to lower production volumes.

Supply Chain and Procurement

The choice of suppliers, material sourcing, and procurement strategies can influence PCB production costs. Selecting reliable suppliers with competitive pricing, managing material quality, and optimizing logistics and transportation can lead to cost savings. Additionally, exploring outsourcing options and establishing strong partnerships may offer cost advantages.

Technological Innovations and Market Trends

Technological advancements and market trends can influence PCB production costs. The introduction of new materials, manufacturing techniques, and automation technologies can impact production efficiency and costs. Furthermore, market competition and price pressures may drive manufacturers to optimize processes and reduce costs to remain competitive.

Why is it important for electronic equipment manufacturers and designers to manage the cost of PCB production?

Here are several reasons explaining its significance:

Competitiveness

Controlling the cost of PCB production enables manufacturers to maintain competitiveness in the market. In today's highly competitive electronics industry, reducing production costs helps companies offer more competitive product pricing and attract a larger customer base.

Profit Maximization

By managing and controlling the cost of PCB production, manufacturers can increase their profit margins. Lower costs mean companies can sell products with higher profit margins, leading to greater returns.

Resource Optimization

Properly managing the cost of PCB production helps companies effectively manage their resources. By optimizing material selection, manufacturing processes, and the supply chain, businesses can reduce waste, improve resource utilization, and lower unnecessary expenses during production.

Quality Assurance

Controlling the cost of PCB production ensures product quality and reliability. Investing the appropriate funds and resources in high-quality materials, processes, and testing equipment can enhance product quality and reduce the risk of product failures.

Design Flexibility

Understanding and managing the cost of PCB production provides designers with greater flexibility. Considering cost factors during the design process helps designers make informed decisions to balance functionality, performance, and cost requirements in product design.

Customer Satisfaction

By effectively managing the cost of PCB production, companies can offer more competitive prices and higher product quality, leading to increased customer satisfaction. Meeting customer demands and providing cost-effective products enhances a company's reputation and market share.

In summary, controlling PCB production costs is crucial not only for a company's competitiveness and profit maximization but also for resource optimization, quality assurance, design flexibility, and customer satisfaction. In today's highly competitive market environment, focusing on and managing PCB production costs is one of the key factors for success.

GET YOUR PCB SUPPORT FROM Shenzhen SprintPCB

Shenzhen Sprint PCB is a leading high-tech enterprise that provides one-stop and high-end PCB manufacturing services to clients worldwide. At Shenzhen Sprint PCB, our extensive experience and competitive pricing enable you to focus on the most critical needs in your organization with a streamlined process. Contact us today to learn more about how we can help you.