PCB (printed circuit board) is printed circuit board, referred to as printed board, Rogers PCB is one of the important components of the electronic industry. Almost electronic device, from electronic watches and calculators to large computers, communication electronics weapon systems, where there are electronic components such as integrated circuits, uses printed boards to make the electrical interconnection between the components. Rogers PCB is one of them. Let me tell you about Rogers PCB.

We will cover the following topics in this blog

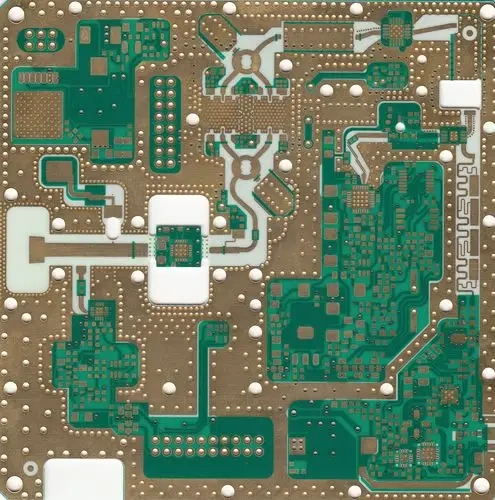

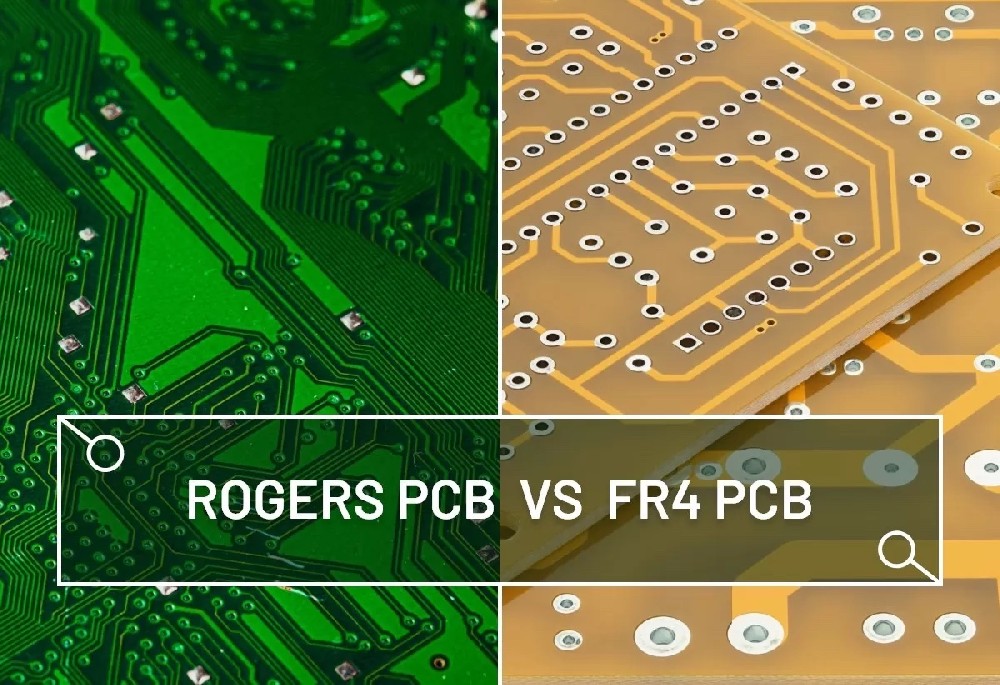

Rogers PCB is a high-frequency board model produced by Rogers Company. Unlike the conventional epoxy PCB board, it has no glass fiber in the middle, but a ceramic base as the high-frequency material. The board contains an epoxy core, metal plated with copper and aluminum. The surface is coated with aluminum.Rogers PCB are designed for use in high -frequency circuit board.

As a high-frequency PCB, Rogers PCB is one of the most widely used and widely sold FR-4 grade materials. These qualities make it suitable for a variety of applications, including antennas, wireless communications equipment, automotive electronics, home appliances, aerospace products.

Roger PCB is mainly used in high-frequency and high-speed design. Rogers' excellent dielectric constant and ability to withstand high temperatures make them the best quality PCBS for RF products and microwave equipment. They are available in a variety of types depending on the desired PCB board resistance and high dielectric constant. Roger PCB has low gas emission, which is an important characteristic necessary for the aerospace and aviation industry. Rogers PCB materials are often used in automotive collision avoidance systems, satellite systems, radio systems and other fields. With the continuous development of communication technology, applications in high-frequency, microwave, and radio frequency fields are becoming increasingly widespread. In these fields, high-performance circuit boards are crucial components. Rogers PCB is a type of printed circuit board made using Rogers material, which has excellent electrical, thermal, and mechanical properties, making it widely used in high-frequency, microwave, and radio frequency circuits. One of the advantages of Rogers PCB is low loss. Compared to ordinary FR-4 materials, Rogers PCB has lower dielectric loss and lower signal transmission loss, making it widely used in high-speed digital communication and satellite communication. In addition, Rogers PCB also has low dielectric constant, high reliability, and excellent heat resistance, making it widely used in fields such as radar, antennas, and high-speed digital communication. In summary, Rogers PCB is a high-performance circuit board material with excellent electrical, thermal, and mechanical properties, making it widely used in high-frequency, microwave, and radio frequency fields. FR4 is a grade of fire-resistant material, which means that the resin material must be able to self-extinguish after combustion. It is not a material name, but a material grade, so the general board used FR4 grade materials have a very wide variety. But most are composite materials made of tare-function epoxy resins with fillers and glass fibers. FR4 PCB is a common type of printed circuit board made from a substrate of glass fiber and epoxy resin. It has excellent mechanical strength, heat resistance, corrosion resistance, and electrical properties, making it widely used in electronic products. One of the advantages of FR4 PCB is its high strength. Its glass fiber reinforced material gives it excellent mechanical properties, making it able to withstand high loads and high temperature environments. In addition, FR4 PCB has good chemical resistance and can resist chemical solutions, acids, alkalis, and other corrosives. FR4 PCB also has excellent electrical properties. It has a low dielectric constant and dielectric loss, which can provide good signal transmission performance. In addition, it has good insulation properties, which can effectively prevent short circuits between circuit boards. In summary, FR4 PCB is an excellent printed circuit board material with high strength, heat resistance, corrosion resistance, and excellent electrical properties, making it widely used in electronic products. FR4 PCBS (printed circuit boards) are widely used low-cost PCBS that are classified as "best performance" under most environmental conditions. According to the standard, FR4 indicates the flame retardant properties of the composite. FR4 material is the most cost-effective type for circuit board manufacturing. They are lightweight, moisture-proof and have high dielectric strength. FR4 PCBS are suitable for through-hole technology in component installation. As a result, they are widely used in most manufacturing technologies and provide high yields.

Customer support