The electronics industry is undergoing a transformation where devices are expected to be smaller, lighter, and more versatile without compromising on performance. To meet these expectations, engineers and designers are increasingly turning to flexible circuit solutions. At the forefront of this transformation stands the flex PCB board—a design breakthrough that allows electronic circuits to bend, twist, and fold without breaking. Among global manufacturers, SprintPCB flex PCB board solutions set themselves apart through superior engineering, uncompromising reliability, and adaptability to high-performance applications. In this article, we will explore two critical aspects: the core advantages of SprintPCB flex PCBs and their real-world applications across industries.

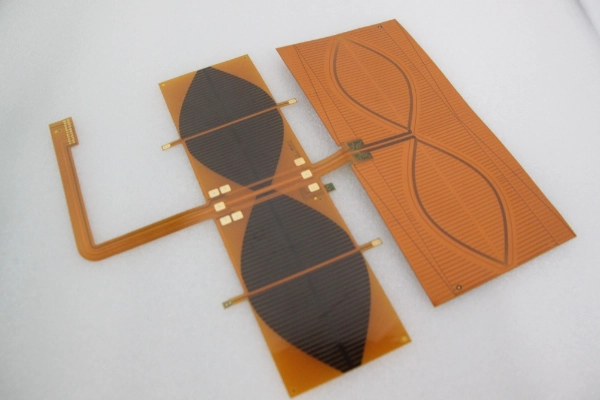

One of the most significant benefits of choosing a SprintPCB flex PCB board is its ultra-thin and lightweight profile. Unlike traditional rigid PCBs, which occupy more space and limit design creativity, SprintPCB offers boards as thin as 0.05 mm with layer counts ranging from 1 to 6.

This compact form factor enables the SprintPCB flex PCB board to integrate seamlessly into devices where every millimeter counts, such as smartphones, medical sensors, and automotive dashboards. The lightweight design also reduces reliance on bulky wiring harnesses and connectors, simplifying assembly and lowering the overall system weight—an essential advantage in today’s drive for miniaturization.

Modern products like aerospace modules, robotic arms, and defense equipment require electronics that can endure constant movement. A SprintPCB flex PCB board is engineered to tolerate continuous bending, folding, and repeated motion cycles without any loss in electrical performance.

For instance, in foldable smartphones, hinge mechanisms subject circuits to thousands of bending cycles. The SprintPCB flex PCB board maintains stable conductivity and mechanical strength even under such stress. This adaptability makes it not only ideal for consumer electronics but also indispensable for robotics and aerospace applications, where long-term durability under dynamic conditions is essential.

Heat management is a key factor in electronic performance. The SprintPCB flex PCB board is designed with excellent thermal dissipation properties, ensuring reliable operation even in confined or high-stress environments.

In automotive dashboards, for example, exposure to sunlight and prolonged system operation can lead to elevated temperatures. The SprintPCB flex PCB board maintains stability and consistent thermal performance in these challenging conditions. By combining flexibility with superior heat resistance, SprintPCB guarantees long-term reliability, even in demanding industrial or automotive environments.

The unique advantages of SprintPCB flex PCBs translate directly into real-world applications. By combining design freedom with reliability, these flexible circuits are now powering some of the most innovative technologies across multiple industries.

Automotive manufacturers are under constant pressure to deliver smarter, more connected vehicles. Instrument panels and dashboard displays have evolved from simple analog gauges into fully digital, multi-functional interfaces.

SprintPCB flex PCB boards play a vital role in these systems. Their ability to withstand vibration, mechanical stress, and temperature fluctuations makes them ideal for the automotive environment. Additionally, the lightweight nature of flex PCBs contributes to vehicle weight reduction, which supports improved fuel efficiency and electric vehicle range.

By eliminating bulky connectors and cables, SprintPCB enables cleaner, more compact dashboard assemblies that not only enhance reliability but also simplify production.

Spacecraft and satellites demand lightweight, compact, and highly reliable electronics that can survive harsh launch conditions and long-term operation in orbit. SprintPCB flex PCB boards are perfectly suited for these missions.

They reduce weight compared to traditional wiring harnesses, improve reliability under continuous vibration, and ensure stable performance despite extreme thermal cycling in space. From navigation modules to communication payloads, SprintPCB delivers the flexibility and dependability required for aerospace innovations.

In medical and healthcare technology, compact and lightweight electronics are critical. SprintPCB flex PCB boards enable advanced medical devices such as diagnostic imaging modules, implantable sensors, and portable monitoring equipment.

For example:

In patient monitoring systems, SprintPCB circuits support reliable signal transmission while allowing compact, ergonomic device design.

In surgical tools and diagnostic probes, flex PCBs withstand repeated sterilization and mechanical stress.

In healthcare wearables, SprintPCB provides thin, skin-friendly electronic layers that remain comfortable and durable.

In industrial environments, robotics and IoT devices must operate reliably under vibration, dust, and temperature fluctuations. SprintPCB flex PCB boards provide the ruggedness and design adaptability required for these scenarios.

Flexible circuits simplify wiring in robotic arms, allow compact sensor integration in IoT nodes, and reduce failure points in high-vibration settings. This results in higher uptime, lower maintenance, and improved data reliability for automation systems.

While many manufacturers provide flexible PCB solutions, SprintPCB distinguishes itself with a combination of technical expertise and customer-focused service.

Precision specifications: SprintPCB offers copper thickness from 8 μm to 70 μm, board sizes up to 250 mm × 610 mm, and multiple finishing options including ENIG, OSP, and gold fingers.

Engineering support: Their team works closely with clients to customize flex PCBs for specific project requirements.

Quality and reliability: Every SprintPCB flex PCB board undergoes rigorous testing to ensure consistency and defect-free performance.

Scalable production: Whether you need prototypes or high-volume production, SprintPCB delivers with speed and reliability.

This combination of cutting-edge specifications and dependable service makes SprintPCB the preferred partner for companies innovating in fast-moving industries.

The rise of lightweight, compact, and high-performance devices has made the flex PCB board an essential technology in modern electronics. SprintPCB has taken this innovation further by delivering boards that are ultra-thin, adaptable to folding, and thermally reliable under stress. From automotive dashboards to foldable displays and flexible sensors, SprintPCB flex PCB boards are powering the next wave of electronic innovation. By combining engineering excellence with practical versatility, SprintPCB ensures that manufacturers can create devices that are not only functional but also future-ready. For businesses looking to integrate flexible circuits into their designs, partnering with SprintPCB means choosing reliability, innovation, and performance.

Customer support