In professional electronics development, time pressure and technical accuracy often collide. Engineering teams are expected to move fast, validate designs quickly, and still deliver boards that meet strict electrical, mechanical, and regulatory requirements. This is exactly where quick turnaround PCB manufacturing becomes a strategic advantage rather than a simple convenience. A well-executed quick turnaround PCB service does not focus on speed alone. Its real value lies in how fast delivery improves engineering efficiency and how consistent quality safeguards project outcomes. This article SprintPCB explores these two critical dimensions and explains why they are the true benchmarks of a reliable quick turnaround PCB solution.

In modern electronics projects, most risks are not discovered on screen—they appear after the first physical board is powered on. Signal integrity issues, EMI behavior, thermal distribution, and assembly constraints often require real hardware validation.

A quick turnaround PCB dramatically shortens the time between design completion and physical testing. Instead of waiting weeks, engineers can receive boards within days, enabling immediate validation and faster iteration. This tight feedback loop allows teams to:

Confirm electrical performance early

Identify layout or stack-up issues before mass production

Adjust component placement based on real assembly behavior

Validate mechanical fit and connector alignment

Faster feedback means fewer late-stage design changes and more confident decision-making.

In many projects, firmware and software development cannot progress without real hardware. Delays in PCB delivery often force teams to rely on simulations or incomplete test setups, slowing overall progress.

With quick turnaround PCB manufacturing, hardware availability keeps pace with software development. Engineers can run real-world tests sooner, allowing firmware optimization, interface tuning, and system-level debugging to begin earlier. This parallel progress significantly reduces overall project timelines.

Engineering resources are expensive. When teams are waiting for boards, productivity drops and schedules slip. A reliable quick turnaround PCB service minimizes idle time by providing predictable delivery windows.

This predictability allows project managers to:

Schedule testing and validation activities accurately

Allocate engineering resources more efficiently

Maintain momentum across development phases

In fast-moving development environments, the ability to plan with confidence is just as valuable as speed itself.

Hardware development is increasingly adopting agile principles. Instead of one long design cycle, teams work through multiple controlled iterations. Each iteration benefits from real-world testing and incremental refinement.

A professional quick turnaround PCB workflow enables this approach by making small-batch production practical and repeatable. Engineers can validate assumptions step by step rather than committing to a final design prematurely.

True quick turnaround PCB efficiency is not achieved by rushing production—it is achieved by avoiding mistakes before production begins. Engineering support plays a critical role in this process.

High-quality quick turnaround PCB services typically include:

DFM checks to identify manufacturability risks

Stack-up validation for controlled impedance designs

Review of drill sizes, tolerances, and annular rings

Early detection of file inconsistencies

By addressing these details upfront, the manufacturing process moves faster with fewer interruptions.

Speed without quality introduces risk. In professional electronics manufacturing, a failed board can cost far more than a delayed one. This is why quality control and service reliability are the second defining pillar of any serious quick turnaround PCB solution.

Quick turnaround PCB manufacturing requires mature, stable processes. Compressing lead time amplifies the impact of any inconsistency, making process control even more critical.

Reliable manufacturers maintain quality through:

Controlled lamination and drilling processes

Stable copper plating and etching parameters

Consistent solder mask and surface finish application

Standardized inspection criteria

Speed must be built on process discipline, not shortcuts.

Even in accelerated production, inspection cannot be reduced. Electrical performance and connectivity must be verified to ensure that boards function as intended.

Professional quick turnaround PCB services typically include:

Electrical testing for opens and shorts

Automated Optical Inspection (AOI)

Visual inspection against defined acceptance standards

These steps protect engineering teams from receiving boards that look complete but fail under power.

Industry certifications are not just formalities—they reflect the maturity of a manufacturer’s quality system. For quick turnaround PCB projects, certifications indicate that speed is supported by documented processes and traceability.

Common certifications in professional PCB manufacturing environments include:

ISO 9001 for quality management

UL for product safety

RoHS for environmental compliance

Industry-specific standards for automotive, medical, and aerospace sectors

Such frameworks help ensure that fast delivery does not compromise compliance or reliability.

For many projects, PCB fabrication is only part of the equation. Assembly quality directly affects functional performance and long-term stability.

When quick turnaround PCB fabrication is combined with in-house assembly, benefits include:

Fewer handoffs and communication gaps

Faster issue identification between fabrication and assembly

Better alignment between design intent and assembly execution

Integrated services reduce risk and further compress total project timelines.

In fast-paced projects, communication matters as much as manufacturing capability. Clear, timely updates allow teams to react quickly if adjustments are needed.

A reliable quick turnaround PCB partner provides:

Fast and transparent quotations

Clear confirmation of manufacturability

Ongoing order status updates

Rapid response to technical questions

This level of service reduces uncertainty and helps teams stay focused on engineering rather than logistics.

Quality does not end at shipment. If an issue arises, how it is handled determines whether a supplier is a true partner.

Professional quick turnaround PCB suppliers typically offer:

Clear and responsive complaint handling

Root-cause analysis through structured reports

Collaborative problem-solving rather than blame

This approach ensures continuous improvement and long-term reliability.

A representative example of a professional quick turnaround PCB provider is SprintPCB. SprintPCB focuses on small to medium batch PCB manufacturing, PCB assembly, and full electronic manufacturing services (EMS), offering end-to-end support from prototype to mass production.

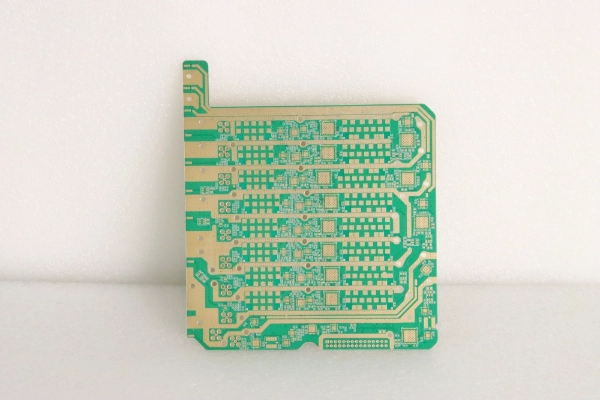

Their manufacturing portfolio covers a broad range of PCB types, including multilayer PCBs, HDI PCBs, high-frequency PCBs, mixed-laminate PCBs, rigid-flex PCBs, flexible PCBs, double-sided PCBs, and metallized half-hole PCBs. This diversity allows quick turnaround PCB projects to be handled without compromising design intent.

Beyond fabrication, SprintPCB provides integrated assembly capabilities such as stencil fabrication, component sourcing, SMT assembly, IC programming, and functional testing. This one-stop approach is particularly valuable for quick turnaround PCB projects where time coordination is critical.

SprintPCB operates under a comprehensive quality framework, holding certifications such as ISO 9001, UL, RoHS, IATF 16949, ISO 13485, AS9100, and QC080000, which reflects their ability to support demanding applications across automotive, medical, and industrial sectors.

What further distinguishes SprintPCB is its emphasis on personalized service. From DFM guidance and material selection advice to one-on-one customer management and responsive after-sales support, the company positions itself not merely as a manufacturer, but as a collaborative PCB solution partner.

A successful quick turnaround PCB solution is built on two essential pillars: engineering efficiency and quality assurance. Fast delivery only creates real value when it enables rapid design validation, shortens development cycles, and keeps hardware progress aligned with software and system-level testing. At the same time, speed must be supported by stable manufacturing processes, disciplined inspection, responsive communication, and structured quality management to prevent costly rework or functional risk. When these two pillars operate together, quick turnaround PCB manufacturing becomes a reliable enabler of project momentum rather than a compromise, allowing engineering teams to move faster with confidence and control.

Customer support