In today's fast-paced electronics industry, where performance, reliability, and cost-effectiveness drive decision-making, the double sided copper clad PCB board has emerged as a go-to solution for many engineers and product developers. This type of PCB design provides higher routing density, better thermal performance, and more flexible component placement than single-sided boards, without incurring the full cost of multi-layer designs. When it comes to manufacturing double sided copper clad PCB boards, SprintPCB stands out as a trusted partner. Specializing in precision engineering and high-quality fabrication, SprintPCB delivers boards that meet the demanding requirements of industries ranging from consumer electronics to industrial automation. With advanced capabilities in CNC drilling, solder mask printing, and automated optical inspection (AOI), every board is produced with exceptional accuracy and consistency—whether for rapid prototyping or large-scale production. In this article, we will explore the advantages of the SprintPCB double sided copper clad PCB board, illustrating why it is the ideal choice for engineers seeking a balance between performance and cost.

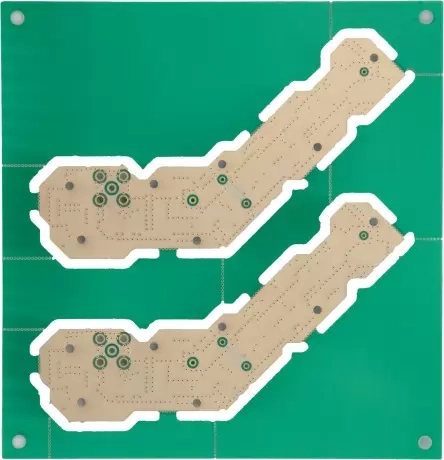

A double sided copper clad PCB board consists of a dielectric substrate with copper foil laminated on both the top and bottom surfaces. Both layers are patterned with conductive traces to form circuits, and interconnections between the two sides are made using plated through holes (PTHs) or vias. This construction enables complex and compact circuit designs that are impossible to achieve with single-sided boards.

For example, imagine designing a compact power supply module that integrates multiple voltage rails, control logic, and thermal management in a limited space. A single-sided PCB would require excessive jumper wires or a larger footprint, while a double sided copper clad PCB board allows you to route signals efficiently on both sides, reducing size and improving signal integrity.

The SprintPCB double sided copper clad PCB board offers a combination of structural and functional benefits that make it far superior to single-sided designs, especially in applications where both performance and cost-efficiency matter. By utilizing copper layers on both sides of the substrate and connecting them with plated through holes, SprintPCB enables designs that are more compact, thermally stable, and electrically reliable. These advantages make it the preferred choice for many mid-complexity electronics, from consumer gadgets to industrial automation equipment.

One of the most significant advantages of a SprintPCB double sided copper clad PCB board is the ability to achieve much higher circuit density compared to a single-sided alternative. With copper layers on both sides, routing possibilities double, allowing engineers to create intricate circuit layouts without increasing board size. This is critical for devices where space is limited, such as smartphones, smartwatches, medical monitoring devices, and compact industrial controllers.

In practice, this means designers can place signal traces on both layers, strategically using vias to connect them, which minimizes crossover issues and eliminates the need for bulky jumper wires. SprintPCB's advanced CNC drilling and precision copper patterning ensure that even the most complex two-layer designs maintain signal integrity and mechanical stability, while keeping the board footprint small and lightweight.

Thermal performance is a major concern in modern electronics, especially for high-power applications. A SprintPCB double sided copper clad PCB board addresses this challenge effectively by using copper layers on both sides to spread and dissipate heat evenly. The additional copper layer increases the total conductive area, helping to transfer heat away from heat-generating components like MOSFETs, voltage regulators, and high-brightness LEDs.

For example, in LED drivers or motor control circuits, poor thermal management can lead to reduced efficiency, shortened lifespan, and component failure. SprintPCB's manufacturing process ensures that both copper layers are laminated with excellent adhesion and uniform thickness, providing a stable thermal pathway. This, combined with optional thermal vias, allows heat to move efficiently from one side of the board to the other, where it can be dissipated through heatsinks or external enclosures.

With a SprintPCB double sided copper clad PCB board, components are not restricted to one surface of the board. Instead, engineers can place through-hole and surface mount devices (SMDs) on both sides, significantly improving layout flexibility. This dual-side placement not only optimizes signal routing but also reduces electromagnetic interference (EMI) by enabling better separation of sensitive and noisy signal paths.

For example, power-handling components can be positioned on one side while control and logic circuits are placed on the opposite side. This arrangement helps maintain clean signal integrity and prevents noise coupling. SprintPCB's precise solder mask printing and AOI inspection ensure that component pads on both sides are perfectly aligned, enabling high assembly yields and reducing rework during manufacturing.

A SprintPCB double sided copper clad PCB board improves electrical performance by enabling shorter, more direct signal paths. Distributing traces between two copper layers reduces the need for long routing detours, which in turn minimizes parasitic inductance and capacitance. This is especially critical in high-speed digital circuits, RF applications, and sensitive analog designs where signal degradation can impact overall functionality.

For instance, in communication modules or precision measurement equipment, signal reflections, crosstalk, and impedance mismatches can severely affect performance. By splitting the routing across both layers, SprintPCB helps maintain controlled impedance and stable signal propagation. The result is a board that delivers reliable, predictable electrical behavior under a wide range of operating conditions—whether in a consumer product or a mission-critical industrial system.

Selecting the right manufacturer is critical to ensuring the quality and reliability of your products. SprintPCB stands out by combining manufacturing precision, advanced technology, engineering support, and fast turnaround, making them a trusted choice for any project that requires a high-performance SprintPCB double sided copper clad PCB board.

From the start, SprintPCB provides a professional Design for Manufacturing (DFM) review to ensure your files are optimized for production, reducing potential errors and delays. Their advanced CNC drilling, precision solder mask printing, and automated optical inspection guarantee that every board meets exacting quality standards, whether for prototypes or large-scale production.

SprintPCB also offers flexible production capacity, enabling smooth transitions from small test batches to mass production without compromising consistency. Coupled with global delivery capabilities and competitive pricing, they deliver reliable PCB solutions on time, every time.

For businesses seeking a reliable partner to deliver double sided copper clad PCB boards with flawless performance, SprintPCB offers the expertise, advanced technology, and dedicated service to bring your designs to life.

For projects requiring a balance between cost, performance, and reliability, the SprintPCB double sided copper clad PCB board offers unmatched value. With advanced CNC drilling, precision solder mask printing, automated inspection, and thorough reliability testing, SprintPCB ensures every board meets exacting standards—whether for a small prototype batch or large-scale production.

If your next project demands compact, high-density, and durable PCB solutions, SprintPCB has the expertise and capability to deliver.

Customer support