In the fast-moving electronics industry, innovation depends heavily on the ability to translate creative ideas into physical, working products. At the heart of every electronic device lies the printed circuit board (PCB), a foundation that enables power distribution, signal transmission, and system functionality. While generic boards may meet some basic requirements, true innovation often demands something more precise and customized. This is where custom PCB fabrication becomes indispensable.

Custom PCB fabrication is not simply about producing a board—it's about creating a tailored solution that matches the unique requirements of a project. Whether for high-frequency communication systems, compact consumer electronics, or life-saving medical devices, the PCB must be designed and manufactured to exact specifications. That requires a fabrication partner with not only technical capability but also the experience, flexibility, and certifications to guarantee results.

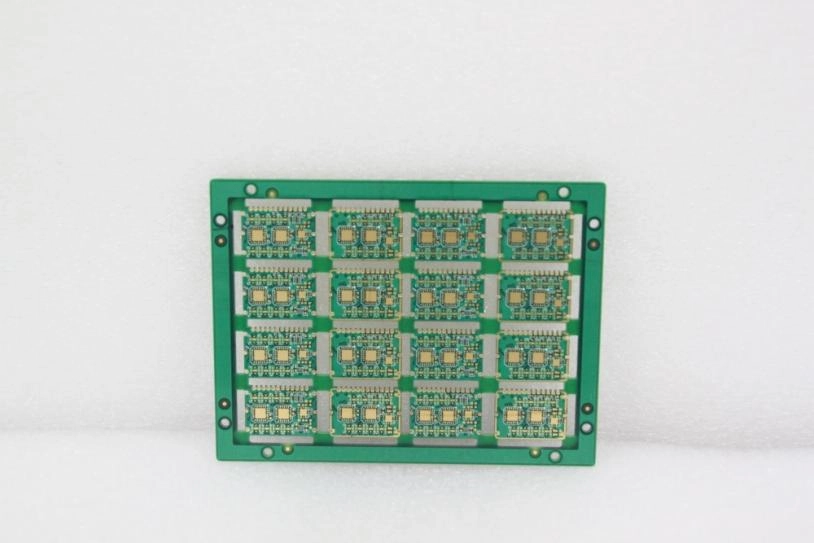

SprintPCB has emerged as a trusted provider in this space, offering a complete range of solutions for small- and medium-batch PCB manufacturing, assembly, and electronic manufacturing services (EMS). From prototyping to mass production, SprintPCB ensures speed, reliability, and quality, backed by cutting-edge facilities and a team of experienced engineers. This article explores why SprintPCB is the right choice for businesses seeking dependable custom PCB fabrication.

Printed Circuit Boards (PCBs) are more than just the physical foundation of electronics—they directly influence performance, reliability, and manufacturability. Unlike off-the-shelf solutions, custom PCB fabrication ensures that every design is perfectly aligned with the specific requirements of each project. Here's why it makes a difference:

Every electronic product has unique needs in terms of size, power, and mechanics. A wearable device may require a flexible PCB that bends with motion, while an automotive system may demand a rigid, high-temperature-resistant PCB. With custom PCB fabrication, engineers can select the right materials, adjust layouts, and optimize dimensions to ensure products perform exactly as intended.

Performance depends heavily on material selection and manufacturing precision. In high-frequency applications like 5G networks or radar systems, low-loss substrates are essential to minimize signal degradation. In LED lighting, metal-core PCBs provide superior thermal management, preventing overheating and extending lifespan. Without a customized fabrication approach, these performance goals would be impossible to achieve.

A successful PCB must be both functional and manufacturable at scale. SprintPCB applies design-for-manufacturability (DFM) principles to help clients simplify structures, reduce unnecessary layers, maximize panel efficiency, and choose cost-effective finishes. This approach ensures that projects meet technical targets while staying within budget, making custom PCB fabrication a smart long-term investment.

Different industries impose strict standards that generic PCBs cannot meet. Medical devices require traceability and certifications, automotive electronics must withstand vibration and extreme temperatures, and aerospace PCBs need uncompromising safety and reliability. Custom PCB fabrication delivers the precision, compliance, and durability needed for these demanding sectors.

By focusing on flexibility, performance, manufacturability, and industry-specific needs, SprintPCB ensures that customers are never limited by off-the-shelf solutions. Instead, they receive custom PCB fabrication tailored to their applications—unlocking opportunities for higher performance, cost efficiency, and true innovation.

In the world of custom PCB fabrication, reliability is never optional—it is a non-negotiable requirement. Certifications serve as proof that a manufacturer follows globally recognized standards, which is critical for industries such as aerospace, automotive, and healthcare. SprintPCB distinguishes itself with a comprehensive certification portfolio that ensures quality, safety, and compliance at every stage of production:

ISO 9001: Establishes robust quality management systems, ensuring consistent processes and customer satisfaction.

UL Certifications: Confirm that SprintPCB's PCBs meet strict international safety and performance benchmarks.

RoHS Compliance: Demonstrates environmentally responsible manufacturing by restricting hazardous substances.

QC080000: Focuses on hazardous substance process management, essential for eco-conscious industries.

IATF 16949: The gold standard for automotive PCBs, guaranteeing reliability under extreme conditions.

ISO 13485: Validates SprintPCB's capability to produce PCBs for medical devices, where patient safety is paramount.

AS9100: Certifies compliance with aerospace standards, proving SprintPCB's strength in high-reliability sectors.

These certifications elevate SprintPCB beyond being just another fabricator. They position the company as a globally recognized, compliance-driven partner in custom PCB fabrication, capable of meeting both technical and regulatory expectations without compromise. Many competitors lack such breadth of certifications, limiting their ability to serve regulated industries. By contrast, SprintPCB provides customers with complete confidence that every PCB is manufactured to the highest standards of safety, performance, and reliability.

What truly sets SprintPCB apart is its engineering-first philosophy. In today's competitive electronics industry, custom PCB fabrication is not just about having advanced machines—it's about combining technical expertise with customer-focused design support. Many projects fail not because of ideas, but because designs aren't optimized for manufacturability, cost, or performance. SprintPCB bridges this gap by offering hands-on engineering assistance at every stage.

DFM Guidance: Comprehensive design reviews that reduce unnecessary layers, improve panel utilization, and enhance production yield—saving time and cost.

Material Selection Expertise: Helping clients choose the right laminates, copper thickness, or special substrates for high-speed, high-frequency, or thermal-demanding applications.

Cost-Saving Techniques: Practical advice such as stack-up simplification, selective finishing, and optimized layouts to balance quality and budget.

File Verification & Minor Edits: Detailed checks of Gerber and CAD files to correct issues before production, preventing delays and costly rework.

By embedding these services into our workflow, SprintPCB turns custom PCB fabrication into a smoother, safer, and more cost-effective journey for customers. The result is not only a high-quality PCB, but also a smarter path to market success.

In a market full of PCB vendors, SprintPCB stands out by offering more than just boards—we deliver complete solutions and long-term reliability. Here's what makes us different:

Technical Expertise: A skilled engineering team supports every stage, from layout review to production optimization.

Comprehensive Certifications: Covering automotive (IATF 16949), medical (ISO 13485), aerospace (AS9100), and more.

Customer-First Service: Dedicated account managers provide personalized support and rapid response.

End-to-End Solutions: From quick prototyping to high-volume production, assembly, logistics, and after-sales.

Cost Efficiency: Lean processes reduce waste and lower costs while maintaining high quality standards.

Unlike many fabricators that only fulfill orders, SprintPCB builds lasting partnerships. Choosing SprintPCB means choosing a trusted ally in custom PCB fabrication, capable of driving innovation, ensuring compliance, and delivering value at every stage.

In an era where electronics define progress, the importance of reliable custom PCB fabrication cannot be overstated. Choosing the right partner ensures not only smooth project execution but also long-term success. SprintPCB stands at the forefront of this industry, combining technical expertise, engineering support, global certifications, and personalized service to deliver unmatched value. From the earliest prototype to full-scale production, SprintPCB is committed to helping clients innovate with confidence. For businesses seeking more than just a manufacturer, SprintPCB is the clear choice. With SprintPCB, you gain a partner dedicated to precision, quality, and customer satisfaction.

SprintPCB custom PCB fabrication: where innovation meets reliability.

Customer support