High-speed communication systems rely on accurate, low-loss signal transmission. As operating frequencies move into the RF and microwave range, conventional PCB solutions are no longer sufficient. High frequency PCB technology is specifically engineered to support stable signal performance at gigahertz-level frequencies, where material properties, impedance control, and manufacturing precision directly determine system reliability. This article SprintPCB explores materials and real-world applications of high frequency PCB.

A high frequency PCB is a printed circuit board designed to transmit signals typically above 1 GHz, with many modern applications operating well beyond 10 GHz or even 30–40 GHz. At these frequencies, electrical behavior changes significantly compared to low-speed digital circuits.

Key electrical phenomena such as dielectric loss, skin effect, impedance mismatch, and signal reflection become dominant factors affecting performance. As a result, high frequency PCBs demand:

Specialized low-loss dielectric materials

Extremely tight dimensional tolerances

Consistent dielectric constant (Dk) across the board

Accurate impedance-controlled routing

Stable performance over wide temperature and frequency ranges

These requirements distinguish high frequency PCBs from standard FR-4 designs and make material choice and fabrication precision absolutely critical.

In a high frequency PCB design, the dielectric constant (Dk) of the substrate plays a decisive role in signal propagation. High-speed and RF signals travel through the dielectric layer, and any fluctuation in Dk can change signal velocity and impedance. For high frequency PCB applications, maintaining a stable and uniform Dk across the entire board is essential to prevent signal distortion, phase delay, and impedance mismatch. Materials engineered specifically for high frequency PCB manufacturing offer tighter Dk control than standard PCB laminates, making them more suitable for precision signal transmission.

Signal loss becomes increasingly critical as operating frequency rises. In a high frequency PCB, the dissipation factor (Df) indicates how much electrical energy is converted into heat while signals pass through the dielectric material. A high Df leads to excessive insertion loss and reduced signal strength, which can severely impact system performance. Low-loss materials with a low dissipation factor are therefore widely used in high frequency PCB designs to ensure minimal attenuation and stable signal integrity, especially in RF, microwave, and high-speed digital applications.

High frequency PCB systems often operate in demanding thermal environments, such as telecommunications equipment, automotive electronics, and industrial control systems. Temperature changes can affect dielectric properties, leading to frequency drift and performance instability. High-quality materials designed for high frequency PCB applications maintain consistent electrical characteristics over a wide temperature range. This thermal stability is critical for ensuring long-term reliability, repeatable performance, and reduced risk of signal degradation in real-world operating conditions.

At higher frequencies, current tends to flow along the surface of the conductor due to the skin effect. In a high frequency PCB, copper surface roughness directly impacts conductor loss and insertion loss. Rough copper surfaces increase resistance and degrade signal quality, particularly at microwave frequencies. For this reason, high frequency PCB materials often use smooth or low-profile copper foil to minimize signal loss and improve overall transmission efficiency.

Selecting the right materials is a fundamental step in high frequency PCB design. While conventional FR-4 materials may be suitable for low-speed circuits, they often fail to meet the performance requirements of high frequency PCB applications. Advanced laminates with low dielectric constant variation, low dissipation factor, and excellent thermal stability are preferred for RF, microwave, and high-speed communication systems. Proper material selection ensures better signal integrity, lower loss, and consistent electrical performance throughout the product lifecycle.

Modern 5G infrastructure relies heavily on high frequency PCB technology to support extremely fast data transmission and complex signal processing. In 5G base stations and small cells, high frequency PCB boards are used to handle massive MIMO antenna arrays, high-speed RF front-end modules, and millimeter-wave signal transmission. These applications require precise impedance control, low dielectric loss, and excellent phase consistency across multiple signal paths.

A well-designed high frequency PCB ensures low insertion loss and stable electrical performance at high operating frequencies, which is essential for achieving the high data rates, low latency, and network reliability demanded by 5G communication systems. As 5G continues to expand, the role of high frequency PCB materials and manufacturing quality becomes increasingly critical.

Radar systems place extremely high demands on signal integrity and timing accuracy, making high frequency PCB performance a key factor in overall system reliability. High frequency PCBs enable accurate target detection, minimal signal distortion, and precise timing control, even at very high operating frequencies.

In applications such as automotive radar, weather monitoring, and defense systems, high frequency PCBs must maintain consistent electrical characteristics under varying temperatures, humidity levels, and mechanical stress. High-quality PCB materials with stable dielectric properties help ensure reliable radar resolution and long-term performance in harsh operating environments.

High frequency PCBs are widely used in RF antennas and microwave devices where signal loss and impedance stability directly affect system efficiency. Typical applications include RF antenna feed networks, microwave amplifiers, power dividers, couplers, and satellite communication equipment.

In these systems, a high frequency PCB must provide low insertion loss, consistent impedance, and excellent phase stability across the operating frequency range. Advanced PCB materials and precise manufacturing processes help minimize signal attenuation and reflection, enabling efficient power transmission and improved overall system performance in RF and microwave applications.

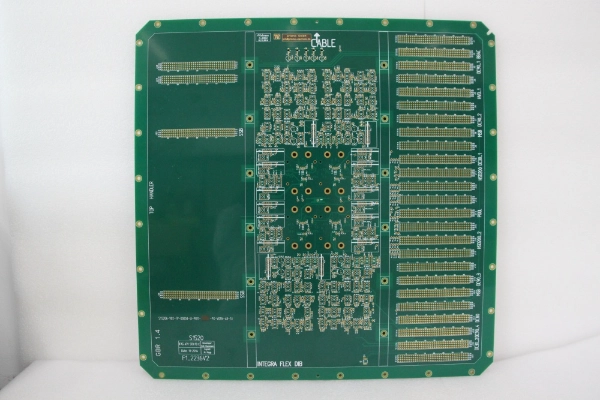

SprintPCB high frequency PCB solutions are developed for RF, microwave, and 5G applications where signal integrity and low loss are critical. By using advanced low-loss dielectric materials capable of supporting frequencies up to tens of GHz, SprintPCB helps minimize signal attenuation and maintain stable performance across wide temperature and frequency ranges.

Through precise impedance control and strict trace geometry tolerances, SprintPCB reduces reflection and insertion loss in high-speed signal paths. These capabilities are particularly valuable for applications such as 5G base stations, radar systems, and RF antenna designs, where electrical consistency directly affects system performance.

SprintPCB specializes in manufacturing high frequency PCBs using PTFE, Rogers laminates, and hybrid laminate structures, and supports customers from prototype development to mass production. For engineers and sourcing teams looking for a reliable high frequency PCB partner with proven RF expertise, SprintPCB offers a practical path from design to production.

High frequency PCB technology is the foundation of modern RF, microwave, and 5G systems. As operating frequencies continue to rise, the importance of low-loss materials, precise impedance control, strict manufacturing tolerances, and signal stability becomes even more critical.

By understanding the technical requirements and working with experienced manufacturers such as SprintPCB, engineers and businesses can achieve superior signal integrity, reduced losses, and long-term reliability across demanding applications.

A well-designed and well-manufactured high frequency PCB is not just a component—it is a strategic advantage in high-performance electronic systems.

Customer support