As a leading

China one-stop PCB assembly factory, SprintPCB specializes in providing comprehensive PCB assembly services tailored to meet the diverse needs of our clients. Our expertise spans from the initial design phase through to full-scale production, ensuring that every aspect of your PCB project is handled with precision and care. Our state-of-the-art facilities and advanced manufacturing techniques position us as a premier provider in the industry.

At SprintPCB, we understand that the success of your electronic products depends on the reliability and performance of the PCBs within them. Our PCB assembly services are designed to deliver high-quality products that meet rigorous industry standards. Here’s a closer look at our core capabilities:

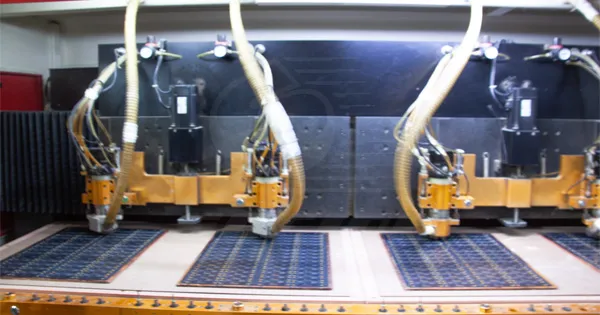

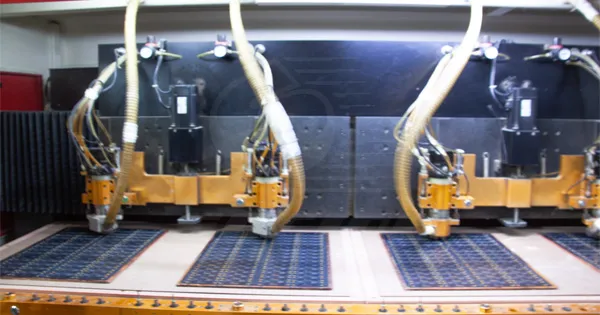

Surface Mount Technology (SMT) Assembly

Our SMT assembly lines are equipped with the latest pick-and-place machines, capable of placing components with exceptional accuracy and speed. This ensures that even the most complex PCB designs can be assembled efficiently. Our SMT assembly process includes:

- Automated solder paste application

- Precise component placement

- Reflow soldering in controlled environments

- Automated optical inspection (AOI) to ensure quality

Through-Hole Technology (THT) Assembly

For components that require strong mechanical bonds, our THT assembly services provide robust and reliable solutions. Our THT process involves:

- Manual and automated component insertion

- Wave soldering for consistent solder joints

- Visual inspection and testing for quality assurance

Mixed Technology Assembly

We are adept at handling PCBs that require a combination of SMT and THT components. Our mixed technology assembly process integrates both techniques seamlessly to produce highly reliable and functional PCBs.

SprintPCB is also renowned for its expertise in specialized PCB fabrication, including HDI printed circuit boards and rigid-flex PCBs.

High-Density Interconnect (HDI) PCBs are essential for applications that demand high performance and compact design. Our HDI PCB fabrication capabilities include:

- Microvias and buried vias

- Laser drilling for precision

- Fine line trace and spacing

- Multilayer stack-ups for enhanced functionality

Combining the advantages of both rigid and flexible PCBs, our rigid-flex PCB fabrication services cater to industries requiring durable and versatile board designs. These PCBs are ideal for applications in aerospace, medical devices, and consumer electronics, offering:

- Enhanced mechanical stability

- Improved signal integrity

- Reduced weight and space requirements

Quality Assurance and Testing

Quality is at the heart of everything we do at SprintPCB. As a China one-stop PCB assembly factory, we implement rigorous quality control measures throughout the manufacturing process. Our quality assurance procedures include:

- Automated Optical Inspection (AOI)

- X-ray inspection for BGA and QFN components

- Functional testing to ensure electrical performance

- Environmental stress testing to verify durability

In addition to full-scale production, SprintPCB offers PCB assembly prototype services. Our rapid prototyping capabilities allow you to test and refine your designs quickly, ensuring they meet your specifications before moving into mass production. Our prototype services are characterized by:

- Fast turnaround times

- Flexibility in design iterations

- Detailed feedback and support from our engineering team

Why Choose SprintPCB?

As a trusted China one-stop PCB assembly factory, SprintPCB is committed to delivering excellence in every project. Our customers choose us because of our:

- Expertise in a wide range of PCB technologies

- Commitment to quality and reliability

- Advanced manufacturing capabilities

- Personalized customer service and support

SprintPCB is also renowned for its expertise in specialized PCB fabrication, including HDI printed circuit boards and rigid-flex PCBs.

SprintPCB is also renowned for its expertise in specialized PCB fabrication, including HDI printed circuit boards and rigid-flex PCBs.