Flex and rigid-flex printed circuit boards (PCBs) offer a range of advantages over rigid PCBs, including flexibility, lightweight materials, and durability. Flex PCBs and rigid-flex PCBs can bend and twist, making them ideal for small and lightweight electronic products that require space and weight optimization. However, these types of PCBs are generally more expensive than rigid PCBs. To reduce costs, there are several strategies you can use. First, it's important to understand the basics of rigid, flex, and rigid-flex PCB materials and their associated costs. Additionally, there are important design-for-manufacturing (DFM) considerations that can impact PCB costs. By taking these factors into account, you can design cost-effective flex and rigid-flex PCBs without sacrificing performance or reliability.

What Are Flex and Rigid-Flex PCBs?

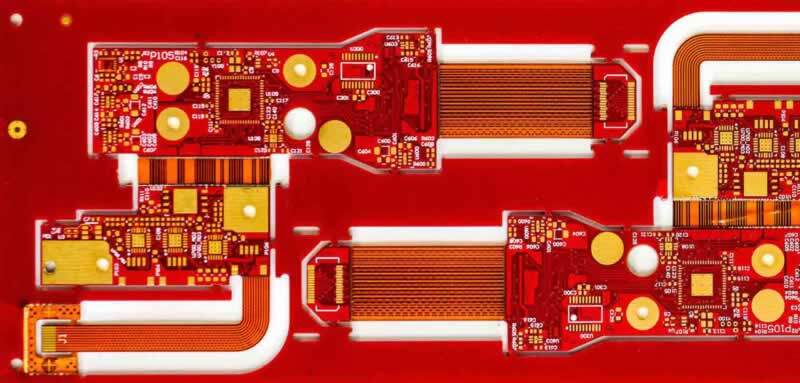

Flex PCBs, also known as flex circuits, are made by laminating a layer of transparent polyester film, such as polyamide, to a thin sheet of copper, which is then etched away to leave the specific PCB pattern in place. These circuits can be fully bent to a specific shape. Rigid-flex PCBs combine rigid PCB materials with flexible circuits, providing the advantages of both. While flex and rigid-flex PCBs are generally more expensive than rigid PCBs, they can help reduce costs in other ways. These boards require less material and offer quicker assembly, as well as a range of design flexibility advantages.

Cost Drivers for Rigid-Flex PCBs and Flexible PCBs

The cost of manufacturing a printed circuit board (PCB) can be heavily influenced by the number of manufacturing steps required and the materials used. Therefore, it is important to understand where the biggest costs come from so that you can design a more economical board that still meets your performance and cost requirements. By optimizing your design and considering factors such as the number of layers, board size, and the complexity of the circuitry, you can help reduce manufacturing costs without compromising on quality or functionality. Additionally, choosing cost-effective materials and finding a reputable PCB manufacturer who can offer competitive pricing can also help bring down the overall cost of production.

Least Influential

To keep your PCB manufacturing costs low, there are some factors that have only a minor impact on your PCB's cost. These include:

More Influential

To maintain the structure and keep costs down, here are some factors to consider for your flex or rigid-flex PCB:

Most Influential

Finally, the following factors significantly affect the cost of your PCB:

Trade-Offs in Cost for Flex and Rigid-Flex PCBs

The previous factors we discussed are important in driving up the cost of PCB design, but it is important to consider the trade-offs that come with lower-cost designs. When considering the affordability of your PCB design, you should keep in mind the following factors: Production panel placement: It is essential to consider how your PCBs will integrate into the production panel. Proper placement can help maximize material utilization and minimize waste. Adhesiveness and reliability: Although adhesive boards are generally cheaper, the addition of acrylic resin in the via stack can impact the reliability of the board, especially in high-temperature or high-stress environments. Line width and spacing: Before adding more layers, consider if you can reduce the width and space of the traces. This can allow you to pack more lines into one layer, minimizing the price. However, consider how these changes may affect the final product and if it may negatively impact performance. Overall, reducing the cost of your flex or rigid-flex PCB design can be achieved by minimizing layers, reducing material thickness, and carefully selecting materials. However, it is important to consider the trade-offs and potential impacts on the performance and reliability of the final product.

Learn More About Flex and Rigid-Flex PCBs

Flex and rigid-flex PCBs offer unique design options that can benefit many projects. By considering the factors that drive up their costs and making design choices that prioritize efficiency and reliability, you can create high-quality PCBs while keeping costs down. If you have any questions about designing flex or rigid-flex PCBs, the team at Sprintpcb can help. As an ISO 9001-certified company, we offer a range of high-quality bare PCBs, including flex and rigid-flex designs. Explore our selection today to learn more about how we can support your project.

Customer support