China PCB manufacturing industry plays a crucial role globally and continues to demonstrate enormous growth potential. PCBs are essential components in electronic devices and are widely used in various sectors such as consumer electronics, communication devices, automotive electronics, and industrial controls. The following will present the scale, position, as well as the challenges and opportunities facing China PCB manufacturing industry. China is one of the largest PCB manufacturing countries in the world, with substantial manufacturing capacity and industry scale. According to data statistics, China PCB production accounts for a significant proportion of the global total output. China PCB manufacturing companies range from small-scale manufacturers to large multinational corporations, covering the entire industry chain from raw material supply to production. Well-known enterprises include Foxconn, Boardtek Electronics Corporation, and Ri-Teng Computer Accessory. China PCB manufacturing level and quality have gradually gained international recognition, with many renowned brands such as Apple, HP, Dell, Samsung, Sony, Huawei, Microsoft, and Intel choosing to manufacture PCBs in China. Many global companies have a high dependence on China PCB manufacturing industry. China PCB manufacturing companies play a crucial role in the global supply chain, providing PCB products to various industries worldwide. This is because Chinese manufacturers can offer diversified products to meet the needs of different industries and supply them at competitive prices. The China PCB manufacturing industry also faces some challenges and opportunities. One of the major challenges is environmental and sustainable development issues. Due to the environmental impact of the chemicals used and the waste generated during the PCB manufacturing process, environmental requirements and regulations are becoming increasingly stringent. Manufacturers need to invest more resources and technology to achieve green manufacturing. Another challenge is the need for technological upgrades and innovation. With the rapid development of the electronics industry and the ever-changing demands, PCB manufacturers need to continually improve their manufacturing processes, design capabilities, and production efficiency to meet market demands. This requires continuous investment in research and development, innovation, and the introduction of new technologies and equipment. However, the China PCB manufacturing industry also presents significant opportunities. With the development of emerging technologies such as artificial intelligence, the Internet of Things, and 5G, the demand for high-performance and highly reliable PCBs is continuously increasing. Chinese manufacturers can leverage these opportunities to gain a competitive advantage in providing innovative solutions and meeting high-end market demands. Additionally, China vast domestic market provides extensive development prospects for PCB manufacturers. China PCB manufacturing industry has a massive scale and position, becoming a crucial link in the global PCB supply chain. Despite facing challenges in environmental and technological aspects, the China PCB manufacturing industry still possesses tremendous development opportunities with technological advancements and the growth of market demand. Continuous technological innovation and investment will be the key drivers for the thriving development of China PCB manufacturing industry.

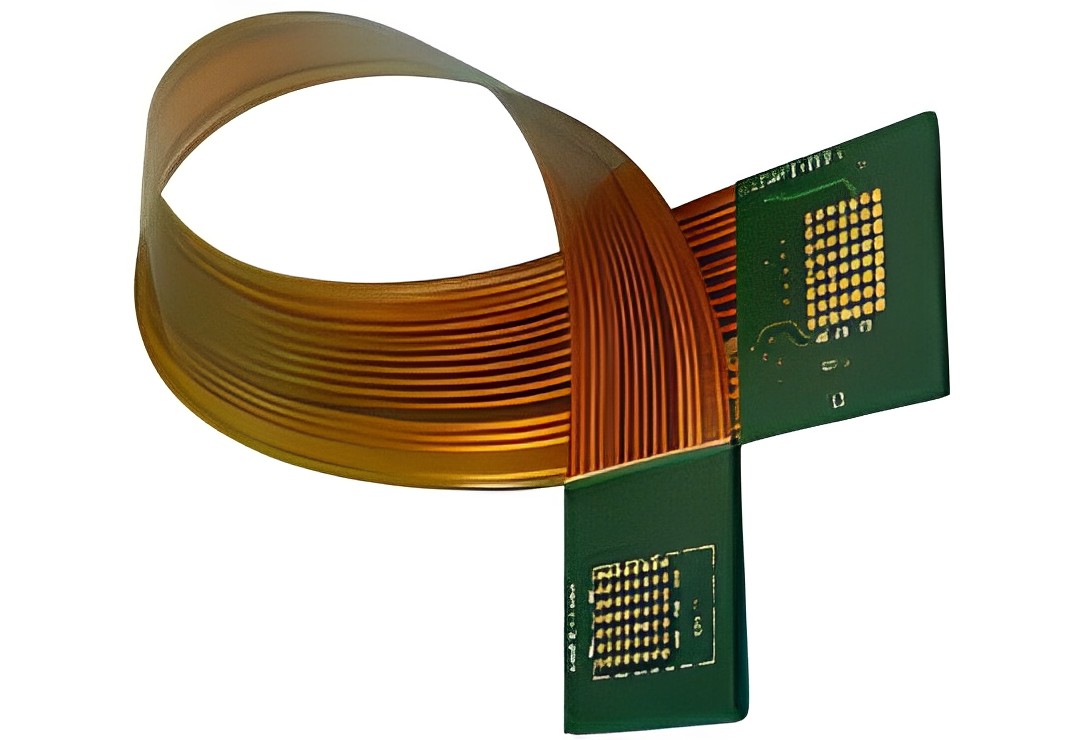

In the Chinese PCB manufacturing industry, there have been some breakthrough innovations that have brought significant changes and advancements to the industry. Flexible electronics technology is a revolutionary innovation that allows electronic components to be made in flexible forms, such as bending, curving, and folding.

Chinese PCB manufacturers have actively engaged in the research and production of flexible electronics technology, driving the development of flexible displays, wearable devices, and bendable electronic products. This innovation not only expands the design and application areas of electronic products but also provides users with more comfortable and portable electronic devices.

High-density interconnection technology is an innovation that achieves higher integration of electronic devices through fine circuitry and miniature components.

Chinese PCB manufacturers have made significant breakthroughs in high-density interconnection technology, enabling electronic products to achieve more functions and performance in smaller sizes. This innovation has propelled the rapid development of smartphones, tablets, and other portable devices, offering consumers more powerful and diverse functional experiences. China PCB manufacturing industry has made significant breakthroughs in green and environmental protection technologies. By adopting eco-friendly materials, improving production processes, and reducing energy consumption, Chinese PCB manufacturers have successfully protected the environment and achieved sustainable development. For example, they have developed lead-free soldering technology, effectively reducing potential harm to the environment and human health. This innovation not only enhances the reputation of China PCB manufacturing industry but also promotes the sustainable development of the global electronics manufacturing industry. To meet the market demand for rapid delivery and customized products, Chinese PCB manufacturers have introduced rapid prototyping manufacturing technology. This technology utilizes advanced manufacturing equipment and processes to produce high-quality prototype circuit boards in a shorter time frame. Through rapid prototyping manufacturing technology, companies can quickly validate and improve their designs, reducing development costs and risks. This innovation accelerates the product development cycle, making the China PCB manufacturing industry more competitive. These breakthrough innovations have had a positive impact on China PCB manufacturing industry. They have driven the industry's development and enhanced the competitiveness of Chinese companies in the global market. In the future, the China PCB manufacturing industry can further explore and develop new areas of innovation, such as high-speed signal transmission, application of new materials, and sustainable manufacturing, to meet evolving market demands and continue leading industry trends. The PCB manufacturing industry in China has made significant progress in innovation and has demonstrated strong development potential. Through discussions on the industry's current situation, innovation trends, and breakthroughs, we can draw the following conclusions: Firstly, innovation is crucial for the development of the PCB manufacturing industry in China. The application of automation and intelligent technologies has made the manufacturing process more efficient and reliable, greatly improving production efficiency. Additionally, the development and use of new materials have brought more options to PCB manufacturing, offering better performance and reliability. Furthermore, breakthroughs have been achieved in PCB design and layout through innovation, improving circuit performance and stability. Secondly, breakthrough innovations have emerged in the PCB manufacturing industry in China. The introduction of new PCB manufacturing processes and technologies has significantly enhanced performance, cost-effectiveness, and functionality. These breakthrough innovations have an important impact on the PCB manufacturing industry in China. They enhance the competitiveness and market position of companies and drive innovative development throughout the industry. With the continuous introduction of new breakthrough innovations, China PCB manufacturing industry is expected to maintain a leading position in the global market. To continue promoting innovation and development in China PCB manufacturing industry, we propose the following recommendations: Firstly, the government and industry organizations should increase support for innovation. Providing funding and policy support to encourage companies to increase research and development investment and promote technological innovation and process breakthroughs. Secondly, strengthen industry-academia research collaboration. Establish closer cooperation relationships to facilitate knowledge sharing and technological exchanges between academia and industry, accelerating the transformation and application of innovative achievements. Furthermore, cultivating and attracting high-quality talents is also crucial. Enhance vocational education and skills training, provide a favorable talent development environment, and attract outstanding scientific and technological talents to join the PCB manufacturing industry. Lastly, strengthen international cooperation and market expansion. Collaborate with international advanced companies and institutions, introduce advanced technologies and management experience, expand international markets, and enhance the global competitiveness of China PCB manufacturing industry. In conclusion, the PCB manufacturing industry in China has achieved significant breakthroughs and progress in innovation. Through continuous innovation and development, China PCB manufacturing industry is expected to play a more important role in the global market, bringing more opportunities and challenges to the industry.

Customer support