PCB (Printed Circuit Board) is an essential component in electronic products, carrying the connections and electrical signal transmission between electronic components. As one of the largest PCB manufacturing countries globally, China plays a significant role in the PCB manufacturing industry. However, with rapid technological advancements and intensified global market competition, China's PCB manufacturing industry is facing new opportunities and challenges.

This article aims to delve into the future development trends and opportunities in China's PCB manufacturing industry. Firstly, we will review the current status of China's PCB manufacturing industry, including its scale, development trajectory, and China's position and competitive advantages in the global PCB market. Simultaneously, we will analyze the challenges and issues that China's PCB manufacturing industry currently faces. Secondly, we will focus on the impact of emerging technologies on China's PCB manufacturing industry. The rise of technologies such as Artificial Intelligence (AI), Internet of Things (IoT), and 5G is reshaping the landscape of the global PCB manufacturing industry. We will explore the influence of these technologies on PCB manufacturing and analyze their potential and opportunities for enhancing China's PCB manufacturing competitiveness. Next, we will discuss the development opportunities in China's PCB manufacturing industry. As one of the largest electronic consumer markets globally, China possesses enormous market potential domestically. We will analyze the demand and growth trends in China's domestic market, as well as the impact of the global electronic consumer market on China's PCB manufacturing industry. Additionally, we will introduce the supportive policies and measures implemented by the Chinese government for the PCB manufacturing industry. Lastly, we will present strategies to address challenges and achieve future development. This includes tackling environmental requirements and sustainable development issues, as well as emphasizing the importance of enhancing technological research and development capabilities and innovation. Furthermore, we will highlight the necessity of cultivating talent and improving employee skills to ensure the continuous development and competitiveness of China's PCB manufacturing industry in the global market. Through a comprehensive analysis of the future development of China's PCB manufacturing industry, this article aims to provide readers with insights into the current status, challenges, and opportunities in China's PCB manufacturing industry. It also aims to inspire and guide Chinese companies in their innovation and development within the PCB manufacturing industry in the future.

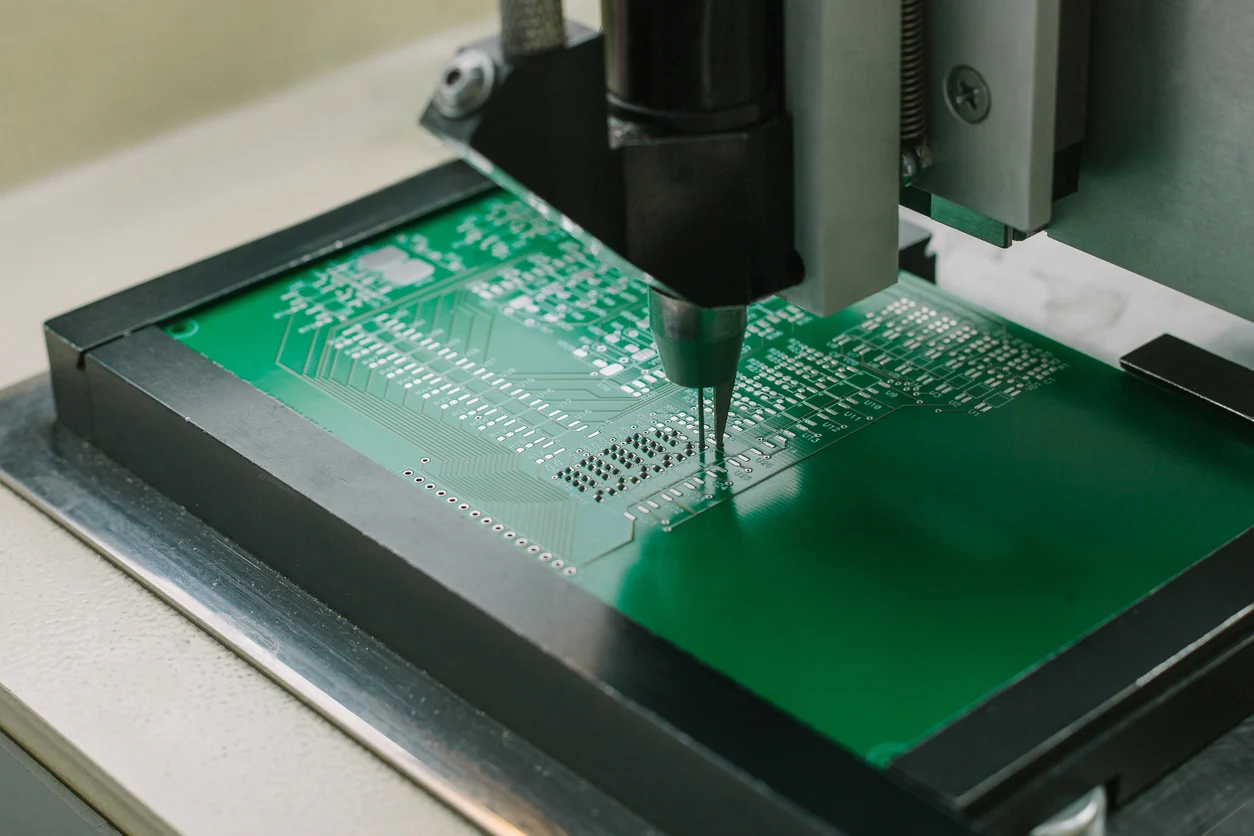

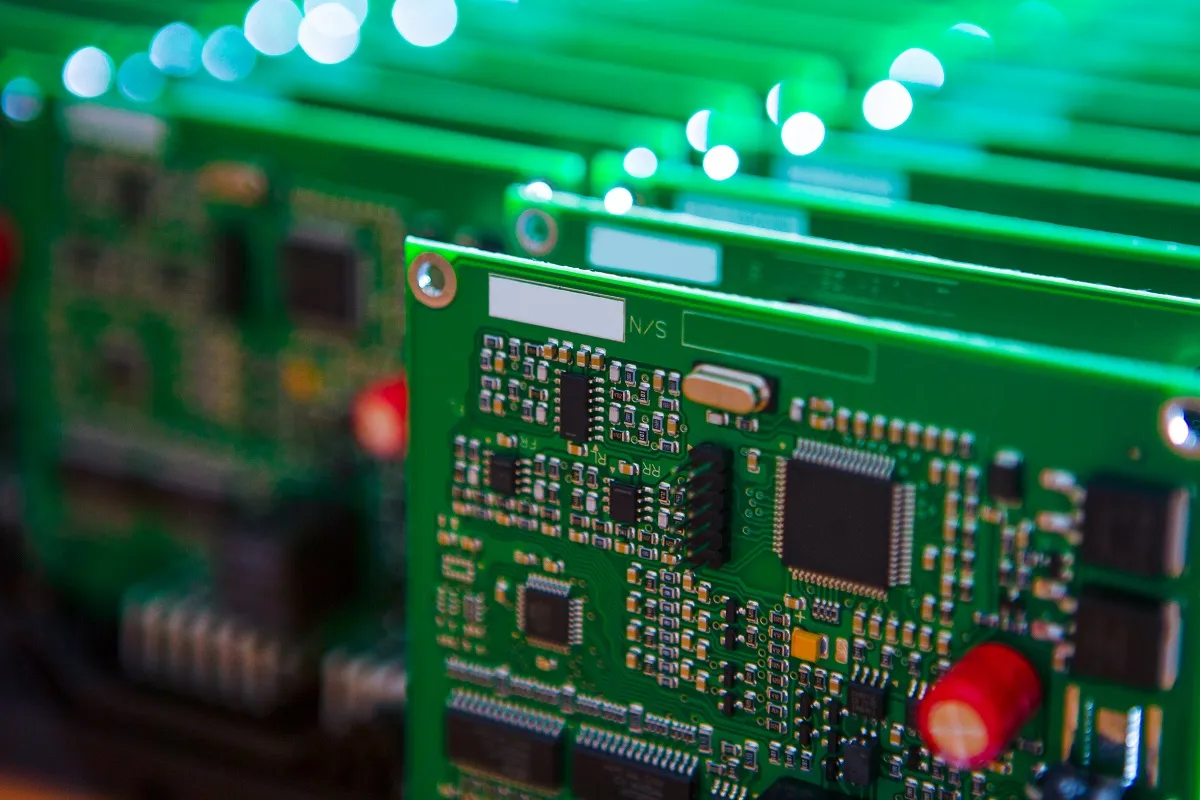

China PCB manufacturing industry boasts a massive scale on a global level. According to statistical data, the Chinese PCB market has maintained high-speed growth over the past few decades. Currently, China has become one of the largest PCB manufacturing countries worldwide. It is projected that the size of China's PCB manufacturing industry will continue to expand and experience robust growth in the coming years. The development of China's PCB manufacturing industry can be traced back to the late 1980s and early 1990s. During that time, China initiated economic reforms and an open-door policy, attracting a substantial amount of domestic and foreign investment and collaboration. This presented significant development opportunities for various manufacturing industries in China, including the PCB manufacturing sector. Initially, PCB manufacturing in China was primarily concentrated in state-owned enterprises and joint ventures. As market demand increased and technology advanced, more and more private enterprises entered the industry. These private companies gained market share due to their flexibility, efficiency, and innovation capabilities, eventually becoming the driving force of the sector. Over time, China's PCB manufacturing industry has undergone continuous rapid development. Chinese manufacturers have enhanced their production efficiency and product quality by introducing advanced technology, equipment, and management practices from abroad. Additionally, the Chinese government has implemented a series of supportive policies to facilitate the industry's growth. China's PCB manufacturing industry has also made significant progress in market diversification. In addition to providing PCBs for the electronics consumer goods and telecommunications industries, Chinese manufacturers have begun to venture into producing PCBs for sectors such as automotive, medical, and aerospace. This diversification of market demand further drives industry growth and innovation. Currently, China's PCB manufacturing industry has established a vast supply chain system. From raw material supply to PCB design, manufacturing, and assembly, Chinese companies offer comprehensive solutions and are capable of meeting the needs of domestic and international customers. China holds a crucial position in the global market for PCB manufacturing. Chinese manufacturers are renowned for their ability to deliver high-quality products at low costs and with fast turnaround times. Chinese PCB manufacturers have also made significant advancements in technological innovation, production efficiency, and economies of scale. These competitive advantages have made China one of the primary destinations for global PCB sourcing. However, the Chinese PCB manufacturing industry also faces certain challenges and issues: Environmental pollution and sustainable development: The PCB manufacturing process generates wastewater, emissions, and waste materials that exert pressure on the environment. The Chinese government's environmental protection requirements are continuously increasing, and PCB manufacturing enterprises need to adapt to environmental standards and seek sustainable development solutions. Technological innovation and research and development (R&D) capabilities: Despite having a competitive edge in scale and cost, the Chinese PCB manufacturing industry still lags behind international advanced levels in terms of technological innovation and R&D capabilities. Strengthening technological research and development and fostering innovation capabilities are critical to enhancing competitiveness. Talent cultivation and employee skills: The PCB manufacturing process requires highly skilled operators and technical professionals. Nurturing high-quality talent and improving employee skills are essential for enhancing product quality and manufacturing efficiency.

Artificial Intelligence (AI) Artificial Intelligence technology is increasingly being applied in the field of PCB manufacturing. AI can enhance the efficiency and accuracy of PCB design through data analysis and pattern recognition, reducing error rates. AI can also be applied to quality control and predictive maintenance during the production process, detecting potential issues in real-time and responding appropriately to improve production efficiency and reduce costs. Chinese PCB manufacturing companies can optimize their design and production processes by adopting AI technology. Moreover, China possesses vast manufacturing data resources that can be utilized for machine learning and model training, thus enhancing the application of AI in PCB manufacturing. Additionally, China can strengthen research, development, and innovation in the field of AI, cultivate more AI talents, and drive further industry advancement.

Internet of Things (IoT) The rise of IoT technology presents new opportunities for the PCB manufacturing industry. With the proliferation of IoT devices, an increasing number of electronic products require the integration of various sensors and connectivity, which rely on PCBs. As one of the world's largest consumer electronics markets, China's development of IoT has generated significant market demand for PCB manufacturing. Chinese PCB manufacturing companies can meet the growing market for IoT devices by researching and producing high-performance PCBs tailored to IoT requirements. Furthermore, IoT applications are driving innovation in PCB manufacturing technology, such as flexible PCBs and embedded PCBs, providing China's PCB manufacturing industry with competitive advantages.

5G Communication Technology With the deployment and application of 5G communication technology worldwide, the demand for high-speed, low-latency communication is increasing. PCBs play a crucial role in 5G devices as they need to support high-frequency and high-speed signal transmission. As a significant participant in the global 5G market, China has immense demand for 5G communication technology. Chinese PCB manufacturing companies can seize this opportunity by providing high-performance PCBs that meet the requirements of 5G communication. Additionally, China can strengthen research, development, and innovation in 5G technology, promote localized production of 5G communication equipment, and enhance its position in the global 5G industry chain.

The development of China's PCB manufacturing industry faces various challenges and obstacles. To achieve sustainable future growth, it is crucial to implement appropriate strategies to address these challenges and drive industry progress. With increasing global demands for environmental protection, Chinese PCB manufacturing companies need to prioritize environmentally friendly production practices and reduce their impact on the environment. This can be achieved by adopting cleaner and more efficient manufacturing processes, such as implementing efficient thermal management systems, energy-saving lighting equipment, and automated control systems. Process optimization, process improvement, and stringent process control can enhance production efficiency and resource utilization. Promoting lead-free processes helps minimize environmental and health hazards. Improving waste treatment and recycling methods, such as treating and purifying wastewater, filtering and purifying exhaust gases, and classifying, recycling, and safely disposing of waste materials, contribute to sustainability. Additionally, leveraging waste recycling and reuse can generate renewable energy or produce recycled materials. Enhancing energy efficiency is also vital. Encouraging companies to obtain green certifications and establish environmental management systems ensures the achievement of sustainable development goals. The future development of the PCB manufacturing industry relies on technological innovation and improved R&D capabilities. Chinese companies should intensify their research and application of emerging technologies, such as high-density interconnect (HDI) technology, flexible circuit boards, and embedded technologies. Actively participating in international cooperation and exchanges allows for the absorption of advanced technologies and management experiences, constantly enhancing innovation capabilities. Furthermore, establishing research and development teams and innovative mechanisms while encouraging employee innovative thinking and knowledge sharing are crucial for future development. Talent is a core element driving the development of the PCB manufacturing industry. Chinese companies should invest in talent development and recruitment, establishing comprehensive talent cultivation systems. This includes collaboration with universities and research institutions, establishing specialized talent development programs, and providing relevant skills training. Additionally, emphasizing employee skill enhancement and career development, encouraging employees to participate in industry associations and international conferences, and continuously learning and updating knowledge are essential. Quality is a key factor for enterprises to thrive in the market. Chinese PCB manufacturing companies should strengthen quality management, establish robust quality control systems, and obtain internationally recognized quality certifications. This enhances competitiveness, improves customer satisfaction, and provides strong support for further expansion into international markets. In the globalized market environment, supply chain management is crucial. Chinese PCB manufacturing companies should enhance communication and collaboration with suppliers and partners, establishing stable and reliable supply chain relationships. By sharing information, improving responsiveness, and fostering collaborative innovation, the efficiency and flexibility of the entire supply chain can be enhanced to adapt to changing market demands. In this article, we have discussed the future trends and opportunities in China's PCB manufacturing industry. Despite facing challenges, the emergence of new technologies presents significant opportunities for the PCB manufacturing industry in China. Technologies such as artificial intelligence, Internet of Things, and 5G will have a profound impact on PCB manufacturing and offer potential for enhancing competitiveness. Additionally, the potential of the domestic market in China and the growth trends in the global consumer electronics market provide favorable conditions for the development of China's PCB manufacturing industry. To address challenges and achieve future growth, it is essential to prioritize environmental sustainability, enhance research and development capabilities, foster innovation, and invest in talent development and skills improvement. Therefore, we encourage Chinese companies to seize the opportunities and drive innovation and development in the PCB manufacturing industry.

Customer support