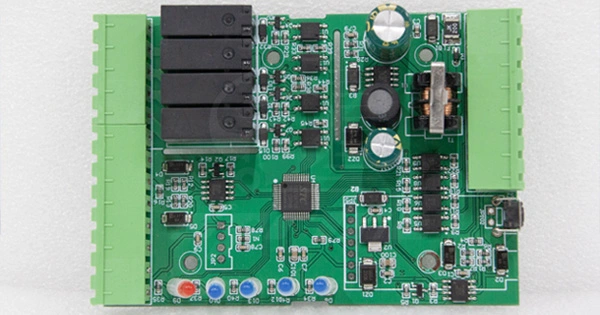

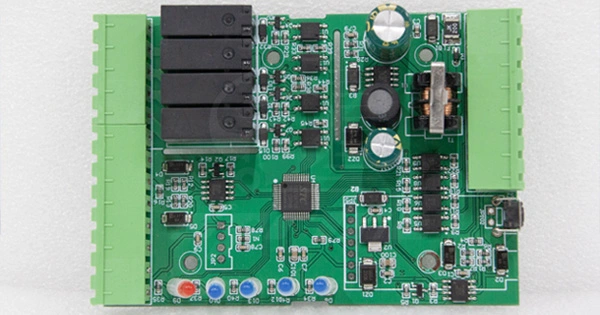

Introduction to PCB Assembly

PCB Assembly (Printed Circuit Board Assembly) is a crucial process in electronics manufacturing that involves mounting various electronic components onto a pre-designed printed circuit board (PCB). The assembly process ensures that the circuit board is functional and ready for use in a variety of electronic devices.

For businesses looking to streamline production, a

low-cost PCB Assembly manufacturer is essential for maintaining both affordability and quality. SprintPCB is dedicated to providing top-tier PCB Assembly services, offering cost-effective solutions without compromising on performance or reliability.

The PCB Assembly Process

The PCB Assembly process consists of several key steps that transform a bare board into a fully operational circuit. Here's an overview of the main stages:

Solder Paste Application:

The assembly process begins by applying solder paste to the areas of the PCB where components will be mounted. This is done using a stencil that matches the layout of the PCB. The solder paste contains tiny particles of solder mixed with flux, which helps in the bonding process.

Component Placement:

Once the solder paste is applied, the components are carefully placed onto the PCB. In modern low-cost PCB Assembly manufacturers, this is typically done using automated machines, such as pick-and-place machines, to ensure precision and speed. These machines are programmed to place components like resistors, capacitors, and integrated circuits in their correct positions.

Soldering:

After the components are placed, the board is passed through a reflow oven where the solder paste is heated until it melts, creating strong electrical connections between the components and the PCB. For through-hole components, wave soldering is commonly used. This method involves passing the board over a wave of molten solder, ensuring all through-hole components are securely attached.

Inspection and Testing:

Quality control is a vital step in the PCB Assembly process. Each assembled board undergoes inspection to ensure that all components are correctly placed and that the soldering is defect-free. Automated Optical Inspection (AOI) is widely used by low-cost PCB Assembly manufacturers to check for soldering issues, misplaced components, and other potential defects. Additionally, functional testing may be performed to ensure the board works as intended.

Packaging and Shipping:

After passing all inspections and tests, the completed PCB assemblies are packaged securely and shipped to customers. SprintPCB ensures timely delivery, whether for small prototype orders or large-scale production runs.

Types of PCB Assembly Services

At SprintPCB, we offer a wide range of PCB Assembly services to meet diverse customer needs:

Surface Mount Technology (SMT):

SMT is one of the most popular methods in PCB Assembly, where components are mounted directly onto the surface of the board. SMT allows for the use of smaller components, making it ideal for high-density circuits used in smartphones, computers, and other compact devices. As a low-cost PCB Assembly manufacturer, SprintPCB ensures that our SMT services remain affordable while maintaining high precision and reliability.

Through-Hole Technology (THT):

Through-hole technology involves inserting component leads through pre-drilled holes on the PCB. This method is often used for components that require a strong mechanical bond, such as connectors or larger components that endure more stress. THT assembly is commonly used in industrial equipment and power supplies, and SprintPCB offers both manual and automated through-hole assembly services.

Mixed Technology Assembly:

In some cases, a combination of SMT and THT components is required for a PCB design. SprintPCB specializes in mixed technology assembly, ensuring seamless integration of both component types for complex, high-performance boards.

Turnkey PCB Assembly:

SprintPCB provides full turnkey PCB Assembly services, managing the entire process from procuring components to manufacturing and assembly. This service is ideal for companies looking for a complete solution without having to manage multiple vendors. As a low-cost PCB Assembly manufacturer, SprintPCB sources high-quality components at competitive prices, passing the savings on to our customers.

Prototyping and Low-Volume Production:

For companies looking to validate their designs before full-scale production, SprintPCB offers rapid prototyping and low-volume PCB Assembly services. This allows for quick iterations and testing of designs, ensuring the final product meets all specifications.

Why Choose SprintPCB as Your Low-Cost PCB Assembly Manufacturer?

SprintPCB is a trusted partner for businesses seeking affordable yet reliable PCB Assembly solutions. Here's why we stand out as a leading low-cost PCB Assembly manufacturer:

Cost Efficiency:

At SprintPCB, we understand the importance of cost savings in electronics manufacturing. Our streamlined processes, advanced automation, and global component sourcing allow us to offer low-cost PCB Assembly services without sacrificing quality. We provide transparent pricing with no hidden fees, ensuring our customers get the best value for their investment.

High-Quality Standards:

While we emphasize affordability, quality remains a top priority. Our state-of-the-art equipment and rigorous testing procedures ensure that every PCB assembly meets industry standards for performance and reliability. SprintPCB is committed to delivering defect-free products that exceed customer expectations.

Fast Turnaround Time:

Time is critical in today's fast-paced markets. SprintPCB offers rapid turnaround times for both prototypes and large-scale production orders. Our efficient assembly lines and experienced team enable us to meet tight deadlines without compromising on quality.

Customizable Solutions:

Every project is unique, and SprintPCB provides tailored solutions to meet specific customer needs. Whether you require a quick prototype, a custom component, or a high-volume production run, we adapt our services to fit your requirements.

Global Reach:

As a low-cost PCB Assembly manufacturer in China, SprintPCB serves customers worldwide. We have the capacity to handle international orders while maintaining affordable shipping options and competitive pricing.

PCB Assembly is a critical aspect of bringing electronic designs to life, and choosing the right manufacturer is essential for success. SprintPCB is a leading low-cost PCB Assembly manufacturer, offering affordable, high-quality assembly services that cater to various industries and applications. With our expertise, advanced technology, and commitment to customer satisfaction, SprintPCB is the go-to choice for businesses seeking reliable PCB Assembly solutions at a competitive price.