In today's fast-paced and interconnected world, electronic products have become an integral part of our everyday lives. From smartphones and laptops to medical devices and automotive systems, we rely on these electronic marvels to perform seamlessly and reliably. The importance of electronic product reliability cannot be overstated.

We expect our devices to function flawlessly, ensuring that critical tasks are completed, communications are uninterrupted, and safety is maintained. Whether it's a medical device providing life-saving treatments or a GPS system guiding us on our travels, the reliability of electronic products directly impacts our quality of life and productivity. Consequently, the pursuit of enhancing electronic product reliability is a paramount concern for manufacturers and consumers alike.

One crucial step in the manufacturing process that significantly contributes to enhancing electronic product reliability is solder mask expansion.

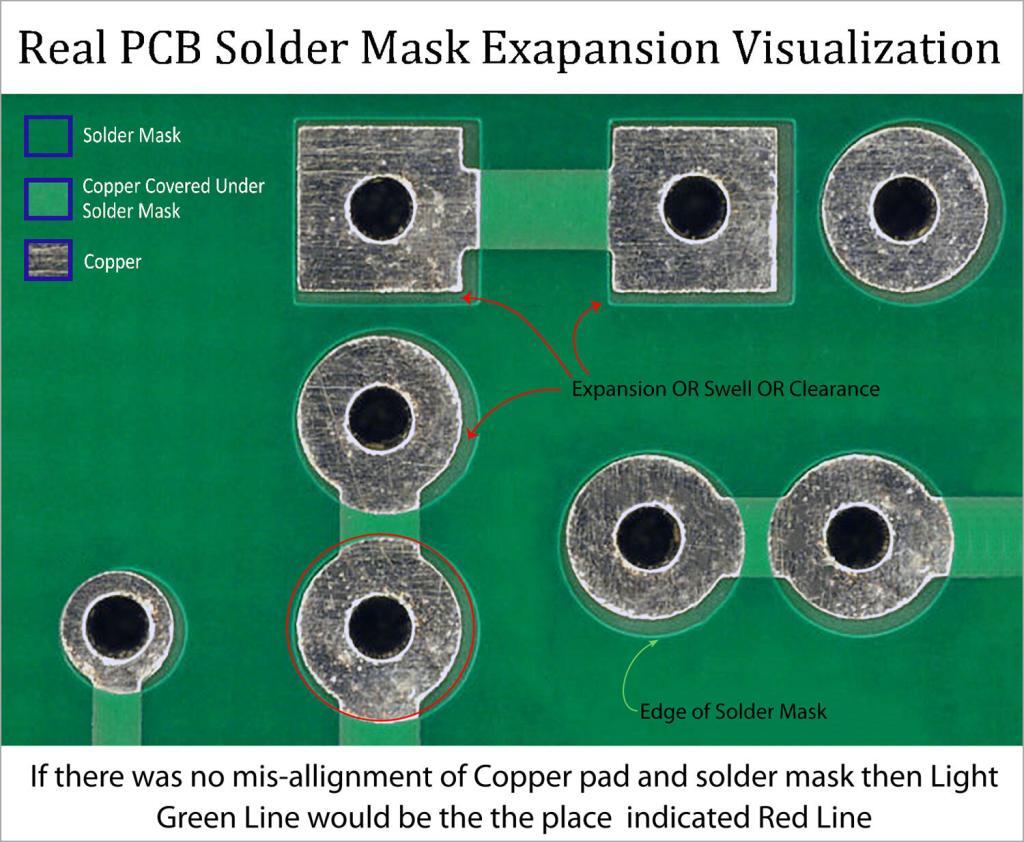

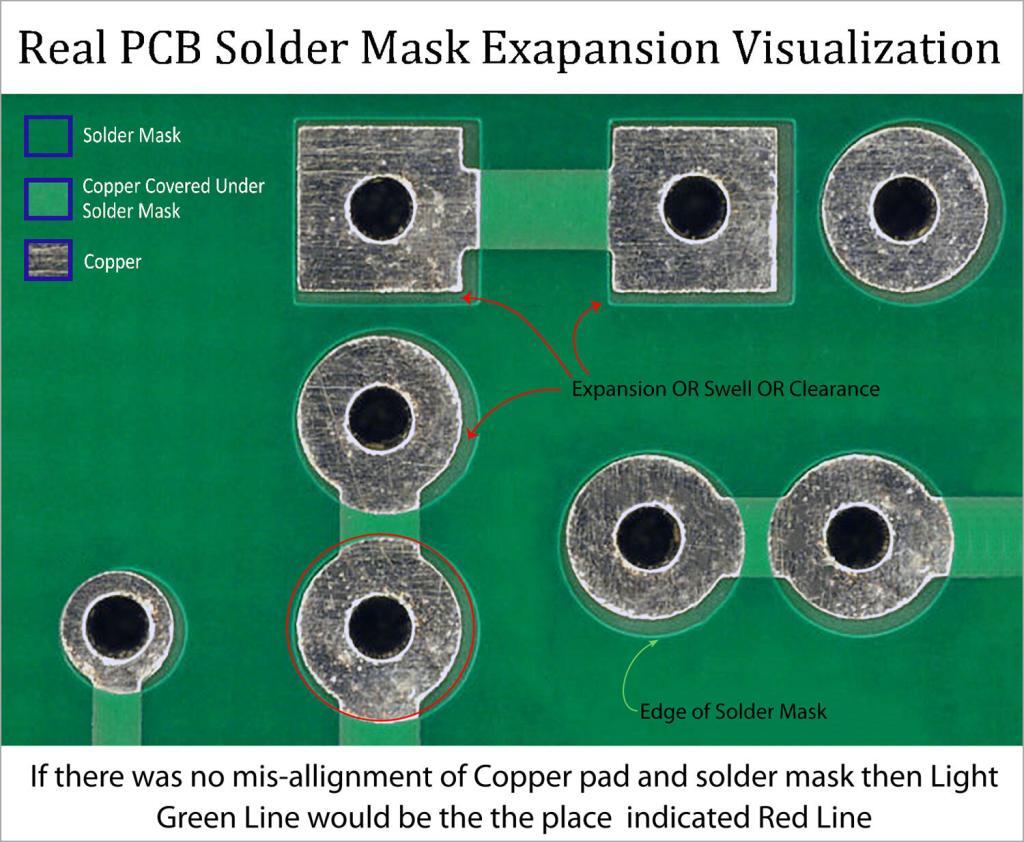

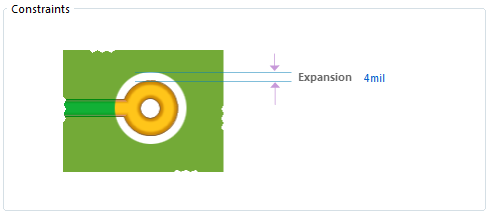

Solder mask expansion, also known as solder mask relief or solder mask dam, refers to the deliberate enlargement of the openings in the protective layer applied to printed circuit boards (PCBs). This protective layer, known as the solder mask, shields the underlying copper traces from accidental contact with solder during the assembly process. By expanding the solder mask openings, we can achieve several critical goals in enhancing electronic product reliability.

Firstly, solder mask expansion ensures proper solder joint coverage. It guarantees that each solder joint on the PCB is adequately protected and insulated from neighboring joints, preventing solder bridges or short circuits that can lead to malfunctions or failures.

Secondly, solder mask expansion minimizes the risk of solder bridging, a phenomenon where solder unintentionally connects adjacent conductive elements. By carefully expanding the solder mask, the spacing between copper traces is increased, reducing the probability of solder bridges, and improving the overall reliability of the electronic product.

Moreover, solder mask expansion provides protection against environmental factors that can compromise the integrity of electronic components. The expanded solder mask acts as a barrier, preventing moisture, dust, and contaminants from coming into contact with sensitive areas of the PCB. Moisture can cause corrosion and electrical leakage, while dust and contaminants can interfere with proper circuit operation.

By effectively sealing and protecting the PCB's components, solder mask expansion ensures that electronic products can withstand challenging operating conditions and maintain their reliability over time.

In summary, solder mask expansion plays a crucial role in enhancing electronic product reliability.

By ensuring proper solder joint coverage, minimizing the risk of solder bridging, and providing protection against environmental factors, this step in the manufacturing process significantly contributes to the longevity and performance of electronic devices. Manufacturers and designers must recognize the importance of solder mask expansion and implement it as an integral part of their manufacturing processes to deliver high-quality, reliable electronic products to consumers.

Understanding Solder Mask Expansion

As we delve into the world of solder mask expansion, it is essential to first grasp the concept itself. Solder mask expansion refers to the deliberate enlargement of the solder mask openings, which are applied to printed circuit boards (PCBs). This protective layer shields the underlying copper traces and prevents solder from flowing onto unintended areas during the assembly process. By expanding the solder mask openings, we can enhance the reliability and performance of electronic products.

Understanding Solder Mask Expansion

As we delve into the world of solder mask expansion, it is essential to first grasp the concept itself. Solder mask expansion refers to the deliberate enlargement of the solder mask openings, which are applied to printed circuit boards (PCBs). This protective layer shields the underlying copper traces and prevents solder from flowing onto unintended areas during the assembly process. By expanding the solder mask openings, we can enhance the reliability and performance of electronic products.

By expanding the solder mask openings, we create a buffer zone around the copper traces, providing additional protection against potential issues like solder bridging and short circuits. This expansion allows for a more reliable and robust assembly, reducing the risk of electrical failures and improving the overall performance of the electronic product.

The role of solder mask in protecting electronic components

The solder mask layer plays a vital role in protecting electronic components on a PCB. It acts as a barrier between the sensitive copper traces and the external environment, safeguarding against various potential sources of damage.

Firstly, the solder mask provides insulation, preventing adjacent copper traces from coming into contact with each other and causing short circuits. This is especially important in densely packed electronic devices where the proximity of traces is high.

Secondly, the solder mask protects the copper traces from environmental factors such as moisture, dust, and contaminants. Moisture, for example, can corrode the copper and degrade the performance of the electronic components, leading to malfunctions or failures. The solder mask acts as a moisture barrier, preventing water or other liquids from reaching the traces and ensuring the long-term reliability of the product.

Additionally, the solder mask offers protection during the soldering process. It acts as a resist to prevent solder from adhering to areas where it shouldn't, such as between closely spaced traces or on non-pad areas. This prevents solder bridges, which occur when solder unintentionally forms connections between adjacent traces or pads, potentially causing short circuits and compromising the functionality of the device.

Explaining the concept of expansion and its benefits

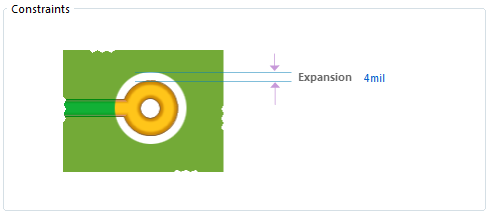

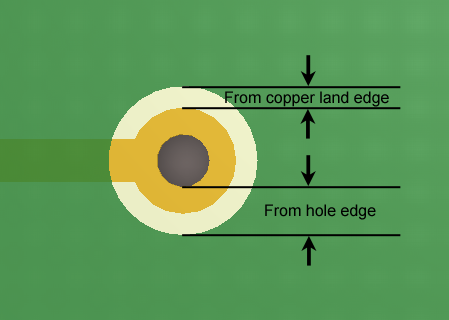

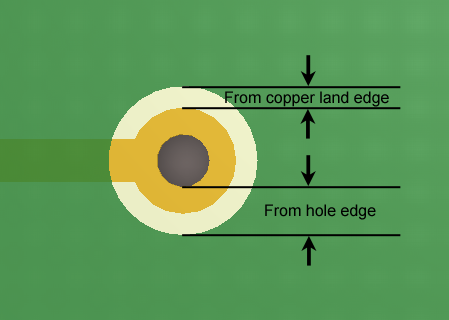

In the context of solder mask, expansion refers to the deliberate increase in the size of the solder mask openings. The purpose of this expansion is to create a margin of error and provide additional space around the copper traces.

By expanding the solder mask openings, we allow for a more forgiving soldering process. This means that even if there are slight misalignments or variations in component placement during assembly, the expanded solder mask will still cover the intended areas and prevent solder from flowing where it shouldn't. It provides a buffer zone that accommodates small deviations, ensuring that the solder joints are well-formed and reliable.

Furthermore, solder mask expansion helps to mitigate the risk of solder bridging. The enlarged openings reduce the likelihood of adjacent solder joints coming into contact with each other, minimizing the possibility of short circuits, and ensuring proper electrical isolation.

Moreover, the concept of expansion enables better manufacturability. It provides a tolerance for potential variations in the manufacturing process, such as misalignments during the application of the solder mask or slight variations in the size of the copper traces. This tolerance contributes to the yield and quality of PCB production, reducing the chances of defects and increasing overall manufacturing efficiency.

In summary, solder mask expansion is a crucial step in PCB manufacturing. By enlarging the solder mask openings, we enhance the protection of electronic components, minimize the risk of short circuits, and provide a tolerance for manufacturing variations. This results in improved reliability, functionality, and performance of electronic products.

The Importance of Solder Mask Expansion

Proper solder mask expansion is vital for various reasons. Firstly, it ensures the coverage of solder joints, ensuring that each joint is adequately protected. Additionally, solder mask expansion minimizes the risk of solder bridging and short circuits, which can lead to malfunctions and failures. Moreover, it provides a barrier against environmental factors such as moisture, dust, and contaminants that could compromise the integrity of the electronic components.

Ensuring Proper Solder Joint Coverage

One of the primary reasons for solder mask expansion is to ensure proper solder joint coverage on printed circuit boards (PCBs). Solder joints are the connections between electronic components and the PCB, and their integrity is crucial for the reliable functioning of the product. Solder mask expansion helps in achieving consistent and reliable solder joint coverage by creating a protective barrier around the exposed copper traces.

When the solder mask openings are appropriately expanded, they align precisely with the copper pads on the PCB. This alignment ensures that the solder paste, which is applied during the assembly process, is confined to the designated areas.

As a result, the solder paste adheres to the copper pads and forms secure and reliable solder joints. Proper solder joint coverage helps prevent issues like insufficient solder volume or incomplete connections, which can lead to malfunctions or failures in electronic devices.

Minimizing the Risk of Solder Bridging and Short Circuits

Solder bridging and short circuits pose significant risks to the functionality and reliability of electronic products. Solder bridging occurs when excess solder connects adjacent pads or traces, forming unintended electrical connections. Short circuits, on the other hand, happen when two or more conductive paths come into contact, allowing an undesired flow of current.

Solder mask expansion plays a crucial role in minimizing the risk of solder bridging and short circuits. By properly expanding the solder mask openings, the distance between adjacent copper traces and pads is increased, reducing the likelihood of unintended solder connections. The expanded solder mask acts as a barrier, preventing the solder from flowing beyond its intended boundaries during the reflow soldering process.

This additional space provided by solder mask expansion also helps prevent short circuits caused by dust, debris, or other contaminants settling on the PCB surface. The solder mask acts as a protective layer, preventing foreign particles from making contact with the conductive areas and causing unintended electrical connections. By minimizing the risk of solder bridging and short circuits, solder mask expansion significantly enhances the reliability and performance of electronic products.

Providing Protection against Environmental Factors

Electronic devices are often exposed to various environmental factors that can adversely affect their reliability and functionality. Moisture, dust, chemicals, and temperature variations are among the common elements that can cause damage or corrosion to electronic components.

Solder mask expansion provides an additional layer of protection against these environmental factors. The expanded solder mask acts as a barrier, preventing moisture or liquids from penetrating the PCB surface and reaching the underlying copper traces or components. Moisture can lead to corrosion, oxidation, or electrical leakage, all of which can compromise the reliability of the product.

Moreover, the solder mask offers resistance to dust and contaminants that may settle on the PCB surface. These contaminants can cause short circuits or interfere with the electrical signals, leading to malfunctions or failures. The expanded solder mask restricts the access of dust and contaminants to the conductive areas, thereby reducing the risk of such issues.

Additionally, solder mask expansion can provide a degree of protection against temperature variations. The expanded solder mask helps to distribute heat evenly during soldering and prevents localized hotspots, which can stress the components and affect their reliability. Furthermore, it offers some insulation against extreme temperatures, shielding the components from thermal shocks or thermal cycling.

By providing protection against moisture, dust, chemicals, and temperature variations, solder mask expansion enhances the durability and reliability of electronic products, especially in challenging operating environments.

Overall, solder mask expansion plays a vital role in ensuring proper solder joint coverage, minimizing the risk of solder bridging and short circuits, and providing protection against environmental factors. These benefits contribute significantly to the overall reliability and performance of electronic devices, making solder mask expansion a crucial step in the manufacturing process.

SprintPCB: Your Reliable PCB Support ProviderSprintPCB is a renowned high-tech enterprise offering comprehensive PCB manufacturing services to clients globally. With our extensive expertise and cost-effective solutions, you can prioritize your organization's critical requirements while enjoying a seamless process. Get in touch with us today and discover how we can assist you.