PCB Surface Treatment (Coating) refers to the application of a solderable coating or protective layer on the PCB's electrical connection points (such as pads, vias, and traces) outside the solder mask. These "surfaces" are the connection points on the PCB that provide electrical connections between electronic components or other systems and the PCB circuitry.

Bare copper itself has excellent solderability but easily oxidizes and gets contaminated when exposed to air, which is why

PCB surface treatment is necessary.

Spray Tin

Definition of Spray Tin:

Also known as Hot Air Solder Leveling (HASL). This involves coating the pads and vias on the PCB surface with molten Sn/Pb solder and leveling it using heated compressed air, forming a copper-tin intermetallic compound.

Types of Spray Tin:

Lead-free spray tin and leaded spray tin. Lead-free is required to comply with environmental (RoHS) regulations.

Advantages of Spray Tin:

- Low cost

- Mature process

- Strong oxidation resistance

- Excellent solderability

Disadvantages of Spray Tin:

- Pads may develop a rough surface (orange peel effect)

- Insufficient flatness for fine-pitch components

Definition of ENIG:

Also known as Electroless Nickel Immersion Gold. This process deposits a layer of nickel on the PCB surface conductors, followed by a layer of gold (0.025-0.075um).

Advantages of ENIG:

- Good pad flatness

- Protects both the pad surface and sides

- Suitable for various types of soldering, including bonding

Disadvantages of ENIG:

- Complex process

- High cost

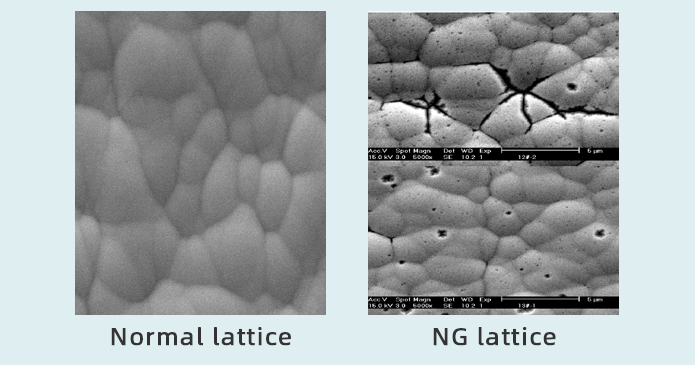

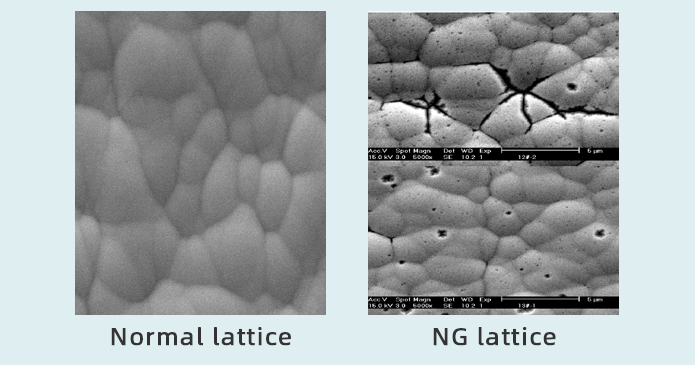

- Risk of black pad defect (nickel layer passivation)

- Nickel layer contains 6-9% phosphorus

- Gold thickness over 5U can cause solder joint brittleness

Immersion Silver

Involves depositing a layer of silver on the PCB pad surface by replacing the copper with silver, resulting in a porous microstructure (thickness typically 0.15-0.25um).

Advantages of Immersion Silver:

- Simple process

- Flat pad surface

- Protects pad surface and sides

- Lower cost than ENIG

- Good solderability

Disadvantages of Immersion Silver:

- Prone to oxidation

- Discolors (yellows or blacks) upon contact with halides/sulfides

- Can cause galvanic corrosion if not controlled, leading to short circuits

- Multiple soldering cycles may degrade solderability

Immersion Tin

Deposits a tin layer on the PCB pad surface by replacing the copper with tin, forming a copper-tin intermetallic compound.

Advantages of Immersion Tin:

- Good solderability similar to HASL

- Flatness comparable to ENIG without intermetallic diffusion issues

Disadvantages of Immersion Tin:

- Short storage life

- Prone to tin whisker formation

- Tin whiskers and tin migration can cause reliability issues during soldering

OSP (Organic Solderability Preservative)

Definition of OSP:

Also known as Organic Surface Protection. This involves coating the PCB surface conductors with an organic compound (typically alkyl-benzimidazole) to protect the pads and vias.

Advantages of OSP:

- Flat pad surface

- Protects pad surface and sides

- Low cost

- Simple process

Disadvantages of OSP:

- Thin coating (0.25-0.45um)

- Poor solderability if not handled properly

- Unsuitable for multiple soldering cycles, especially in lead-free environments

- Short shelf life

- Cannot be used for bonding